The mining industry relies on a wide range of heavy-duty equipment to extract minerals and ores safely and efficiently. Among these, pumps used in the mining industry are critical for water management, slurry transport, and dewatering operations. From small-scale mines to large industrial operations, the right pump ensures smooth production and minimizes downtime.

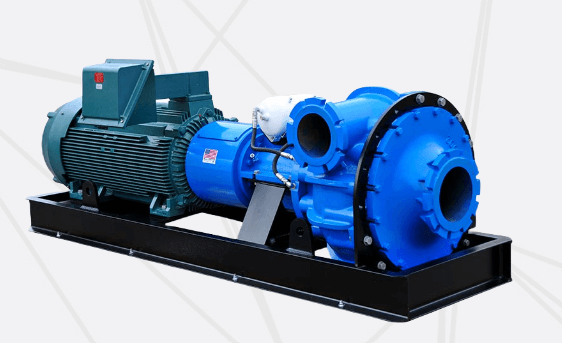

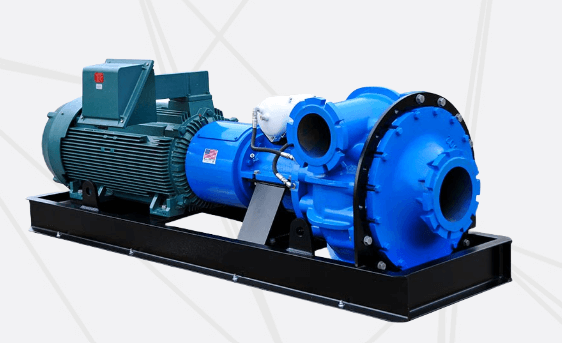

At MultiTorque, we specialize in supplying, servicing, and repairing a wide range of industrial pumps designed specifically for mining applications. With over 15 years of experience, our team delivers reliable, high-quality pumping solutions across Australia.

📞 Call us on 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

https://www.linkedin.com/company/3176927

The Role of Pumps in Mining Operations

Mining operations often involve handling abrasive slurries, contaminated water, and other challenging fluids. The pumps used in the mining industry serve multiple purposes:

- Dewatering: Removing groundwater or process water to keep mines dry and safe.

- Slurry Transport: Moving mixtures of water and ore for processing.

- Chemical Handling: Transporting chemicals used in mineral processing.

- Cooling Systems: Circulating water for machinery and processing equipment.

Choosing the right pump for each application is critical to maintaining operational efficiency and safety.

Common Types of Pumps Used in Mining Industry

Mining operations require specialized pumps built to withstand harsh conditions. Some of the most commonly used pumps include:

1. Centrifugal Pumps

Centrifugal pumps are widely used for water and slurry transport. They work by converting rotational energy into kinetic energy, moving fluid efficiently over long distances. MultiTorque provides a range of centrifugal pumps designed to handle abrasive slurries and high volumes.

2. Progressive Cavity Pumps

These pumps are ideal for viscous fluids and sludge. They provide a smooth, non-pulsating flow, which is essential for delicate processing operations. Progressive cavity pumps are commonly used in tailings management and chemical transport.

3. Slurry Pumps

Specially designed to handle abrasive and solid-laden fluids, slurry pumps are crucial in mineral processing. They can move thick mixtures of water and ore without damage, ensuring consistent production.

4. Dewatering Pumps

Dewatering pumps are essential for removing excess water from mine sites, preventing flooding, and ensuring a safe working environment. MultiTorque’s BoreBoss dewatering units are a prime example of mobile, reliable solutions for mining sites.

5. Chemical Pumps

For transporting acids, alkalis, and other chemicals used in ore processing, chemical pumps offer corrosion resistance and high durability. These pumps protect both the equipment and the environment from leaks and failures.

Factors to Consider When Selecting Mining Pumps

Selecting the right pump for mining industry operations requires consideration of several critical factors:

- Fluid Type: Slurries, clean water, or chemicals each require specific pump materials and designs.

- Flow Rate & Pressure: Pumps must meet the required throughput without overloading.

- Durability: Mining pumps must withstand abrasive materials and continuous operation.

- Energy Efficiency: High-efficiency pumps reduce operational costs over time.

- Maintenance Access: Easy access for repairs and replacement parts minimizes downtime.

MultiTorque works with clients to identify the best pump for their specific mining applications, ensuring maximum productivity and minimal maintenance costs.

Maintenance and Reliability

Pumps in mining environments face extreme conditions, from abrasive slurries to heavy usage. Proper maintenance and servicing are crucial to ensure reliability and long operational life. MultiTorque provides:

- In-house Workshop Repairs: Expert technicians repair and rebuild pumps efficiently.

- Genuine Spare Parts: Only high-quality parts are used to extend equipment life.

- Custom Fabrication: Tailored solutions for unique mining requirements.

- Routine Inspection Services: Preventive maintenance to reduce downtime.

With the right maintenance, mining pumps can operate effectively for many years, saving costs and avoiding costly operational interruptions.

Innovations in Mining Pump Technology

The mining industry continually adopts new technologies to enhance efficiency and reduce costs. Modern pumps used in mining often feature:

- Wear-resistant materials to handle abrasive fluids.

- Variable frequency drives (VFDs) for energy efficiency and precise control.

- Automated monitoring systems for predictive maintenance.

- Mobile dewatering units for rapid deployment on site.

At MultiTorque, we keep our clients ahead of the curve by providing the latest pump technologies and solutions tailored to mining operations.

Applications of Mining Pumps Across Operations

Mining pumps are essential across various stages of mining:

- Extraction: Pumping groundwater and mine water to maintain safe conditions.

- Processing: Transporting slurry to crushers, mills, and concentrators.

- Tailings Management: Moving processed ore and water to tailings ponds.

- Environmental Management: Handling wastewater and chemical runoff responsibly.

Every stage of mining relies on robust and reliable pumping systems to maintain production and comply with environmental regulations.

Why Choose MultiTorque for Mining Pumps

MultiTorque is a trusted supplier and service provider for mining pumps across Australia. Our advantages include:

- Experience: Over 15 years in industrial and mining pump solutions.

- Expertise: Knowledge of all major pump types and applications.

- Customization: Tailored solutions to meet specific mining site requirements.

- Nationwide Service: Supporting mines from Perth to Brisbane with prompt service.

Whether you need centrifugal pumps, slurry pumps, or mobile dewatering units, MultiTorque ensures your mining operations stay efficient and reliable.

Contact MultiTorque Today

If you’re looking for dependable pumps used in the mining industry, MultiTorque can provide expert advice, supply, and repair services to keep your operation running smoothly.

📞 Call us on 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au