Managing water buildup on worksites is more than a maintenance issue—it’s a mission-critical factor for safety, productivity, and compliance. Whether it’s groundwater, surface runoff, slurry, or stormwater, you need a dewatering pump system that works fast, reliably, and with minimal oversight.

At MultiTorque, we specialise in designing, supplying, and supporting industrial-grade dewatering pump systems tailored to the unique conditions of Australian industries. From deep mine shafts to civil construction pits and remote agricultural sites, our pump systems are trusted across the country.

What Is a Dewatering Pump System?

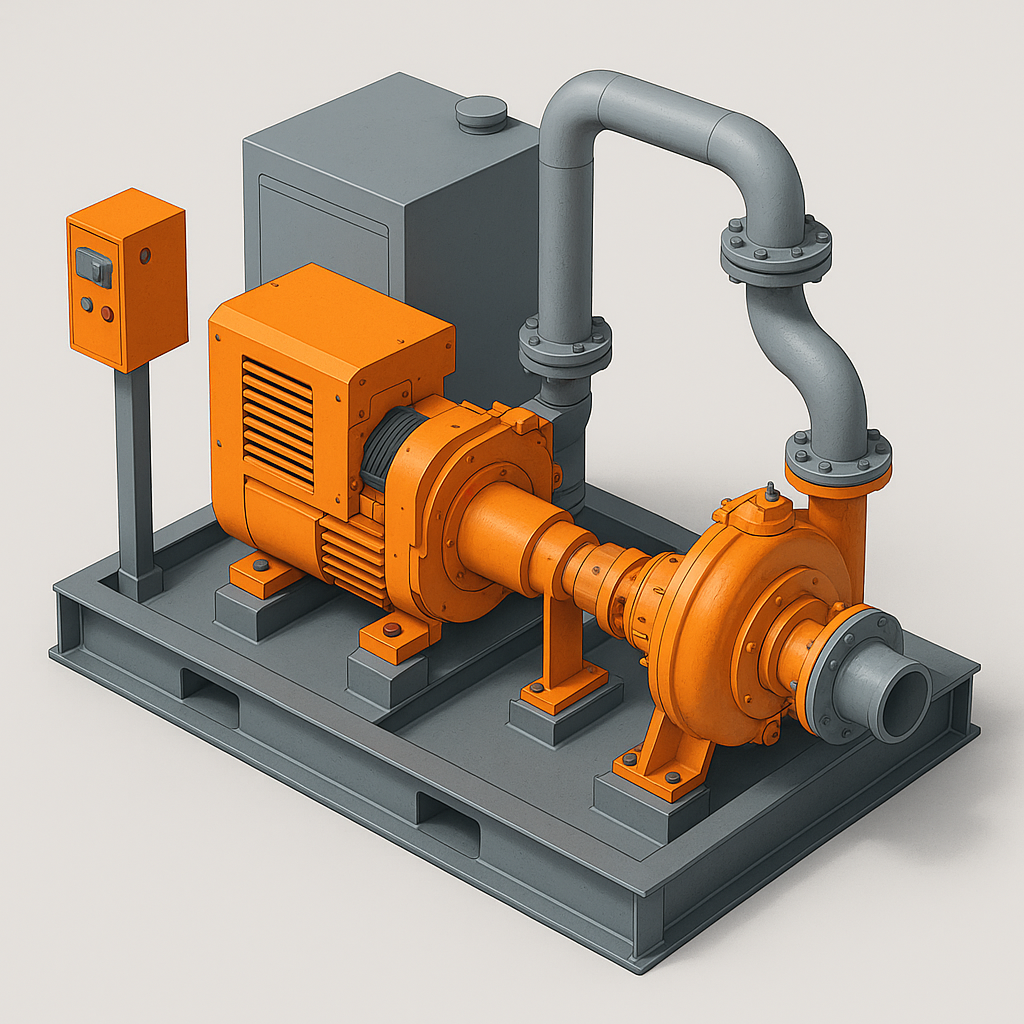

A dewatering pump system is an integrated setup designed to remove unwanted water or fluid from a worksite. It typically includes:

- A primary pump (diesel or electric)

- Intake and discharge hoses

- Float switches or sensors

- Power/control panel or auto-start kit

- Optional: bunded skid or trailer setup for mobility and safety

These systems are essential for keeping areas dry during construction, mining, tunnelling, or emergency flood response operations.

Common Applications of Dewatering Pump Systems

Our dewatering systems are used extensively across:

- Mining – open-cut and underground pit dewatering

- Civil Construction – excavations, trenching, basements, foundations

- Tunnelling & Infrastructure – rail, road, and utilities

- Flood Management – rapid-response setups for stormwater and disasters

- Agriculture & Irrigation – removal of excess water in controlled paddocks or dams

- Industrial Sites – washdown bays, sumps, and waste ponds

Whether you’re pumping clean water or thick sludge, we’ll spec and build the right setup.

Pump Types Used in Dewatering Systems

MultiTorque supplies a wide range of pump types, depending on fluid type, flow rate, and pressure requirements:

- Centrifugal diesel pumps – Ideal for high-volume surface dewatering

- Electric submersible pumps – Perfect for silent, continuous operation

- Trash & slurry pumps – Handle solids, mud, and sludgy water

- Air-driven diaphragm pumps – Great for ATEX zones and tight spaces

- High-head pumps – Designed for deeper pits and longer discharge distances

Each pump is matched to the flow, head, and environment for optimal performance.

Why MultiTorque’s Dewatering Pump Systems Stand Out

✔ Custom-Built

Our team can design and fabricate systems specific to your project. From compact electric submersibles to rugged diesel trailer systems—we build to order.

✔ Built for Australia

Every MultiTorque system is engineered for heat, dust, mud, and distance. With heavy-duty frames, corrosion-resistant components, and easy field service access, these systems last.

✔ Modular & Scalable

Need to expand? No problem. Our systems are designed to scale with your project—just add pumps or extend discharge runs with ease.

✔ Automation Options

Add auto float switches, remote telemetry, or PLCs for hands-free operation—ideal for long-term dewatering.

✔ Fast Dispatch & On-Site Setup

With bases in Perth and Brisbane, we ship quickly and can assist with setup and training on-site.

End-to-End Support and Servicing

When you buy from MultiTorque, you’re backed by a full-service team ready to keep your pump system running:

- Preventative maintenance

- Emergency breakdown support

- Full pump rebuilds and diagnostics

- Spare parts supply

- System audits and upgrades

We also offer on-site servicing across Australia with experienced technicians ready to respond fast.

Trusted Brands We Work With

MultiTorque supplies pump systems from the world’s most trusted names, including:

- Napco

- Wilden

- Orbit

- Atlas Copco

- NOV Mono

- Kubota

- Yanmar

Each pump system is hand-picked and assembled for quality and durability.

Why Choose MultiTorque?

- ✅ Over 15 years of experience in dewatering

- ✅ Custom engineering for unique site needs

- ✅ Service centres in both QLD and WA

- ✅ Fast shipping and honest, local support

- ✅ Long-term partnerships with mining, civil, and industrial clients

We don’t just sell pumps—we build relationships.

Need a Dewatering Pump System? Let’s Talk.

Don’t wait for your site to flood. MultiTorque is ready to supply, service, and support your dewatering needs with systems built for Australian worksites.

📞 Call us on 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: www.multitorque.com.au

🔗 LinkedIn: MultiTorque LinkedIn