Industrial operations across mining, transport, logistics, civil construction, agriculture, marine, and manufacturing depend on fire suppression equipment that performs when conditions are extreme. MultiTorque supplies high-grade suppression components, extinguishers, and advanced aerosol systems designed specifically for heavy-duty, high-risk environments where reliability isn’t negotiable.

With more than 15 years supporting Australian industry—and backed by our acquisition of Fire Safety Equipment (FSEquip)—MultiTorque delivers one of the strongest fire safety supply networks in the country. Our goal is simple: provide the fire suppression equipment that keeps your site operating safely and without interruption.

For orders or product enquiries:

📞 1300 726 525

📧 sales@multitorque.com

Explore our industrial product range:

👉 MultiTorque

Industrial Fire Suppression Equipment You Can Rely On

MultiTorque supplies a wide range of components and equipment tailored to the demands of heavy industry. Whether you’re replacing system parts, upgrading suppression capabilities, or needing fast supply of extinguishers, we deliver the gear that frontline operators trust.

Our fire suppression equipment range includes:

- FirePro condensed aerosol suppression units

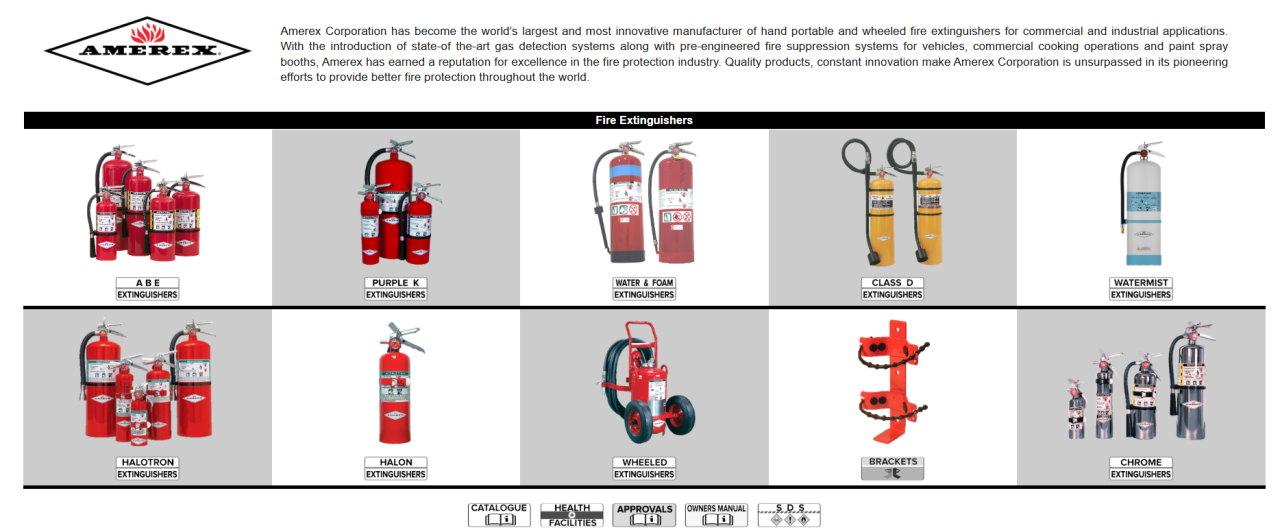

- Amerex fire extinguishers for mining, transport, warehouse, and marine applications

- Electrical activators and detection components

- Fire system hardware, hoses, nozzles, and mounting brackets

- Suppression consumables and replacement parts

- High-temperature detection options

- Thermal actuators and automatic activation components

All equipment is sourced to meet strict Australian standards and withstand high vibration, heat, dust, and demanding operational environments.

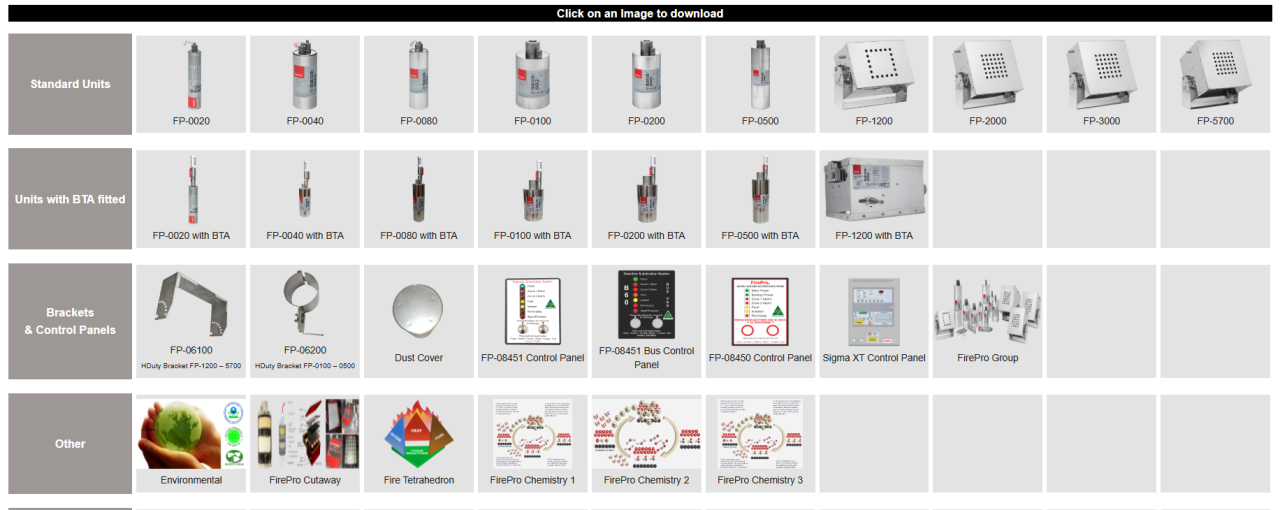

FirePro: The Next Generation of Fire Suppression

MultiTorque is an official distributor of FirePro across Australia and New Zealand, supplying one of the most advanced and compact fire suppression technologies available.

Why FirePro Leads the Industry

- No pressurised cylinders

- No complicated pipework

- Minimal maintenance

- Compact, long-life aerosol generators

- Thermally or electrically activated

- Certified to AS 4487 and AS 5062

- Designed for harsh industrial and mobile plant environments

FirePro Applications:

- Mining & civil mobile plant

- Electrical cabinets and switchboards

- Lithium battery enclosures

- Agriculture and harvesting equipment

- Transport fleets (trucks, buses, rail)

- Marine vessels

- Manufacturing & industrial machinery

- Power infrastructure and telecom cabinets

FirePro provides powerful, fast-acting suppression—making it one of the most versatile fire suppression equipment solutions available on the market.

National Distribution Through FSEquip

Thanks to MultiTorque’s acquisition of Fire Safety Equipment (FSEquip), customers benefit from faster access to fire suppression parts, consumables, and hardware through warehouses located in Brisbane and Sydney.

FSEquip supplies:

- Fire system fittings

- Suppression system consumables

- Brackets, mounts, hoses, and connectors

- Extinguisher parts and hardware

- Industrial fire protection components

Explore Australia’s fire safety supply network:

👉 FSEquip

Fire Suppression Equipment Designed for Industrial Risk

Mining & Heavy Machinery

Mobile plant requires dependable automatic suppression that withstands vibration, dust, extreme heat, and diesel ignition risks. MultiTorque supplies equipment engineered specifically for excavators, dozers, graders, loaders, and haul trucks.

Transport & Logistics

Our suppression solutions support truck fleets, buses, and trailer operations needing reliable extinguishers and component replacement.

Manufacturing & Industrial Facilities

Switchboards, electrical cabinets, process machinery, and automation systems require advanced detection and suppression with minimal downtime.

Marine & Ports

Space-efficient aerosol systems and marine-rated extinguishers provide essential protection for engine rooms and confined spaces.

Agriculture

Equipment like tractors, harvesters, and seeders faces high fire risk due to dust, crop material, and engine temperature. FirePro and our suppression hardware provide dependable coverage.

Power & Energy

Telecom systems, battery banks, and electrical infrastructure demand targeted suppression that activates fast and leaves minimal residue.

Wherever the risk is highest, MultiTorque provides the fire suppression equipment needed to keep your operation safe.

Why MultiTorque Is the Preferred Supplier for Industrial Fire Suppression

- 15+ years supporting heavy-industry operations

- Official FirePro distributor across Australia & New Zealand

- Strong national supply chain through FSEquip

- Large range of industrial extinguishers and suppression components

- Fast dispatch and reliable availability

- Trusted across mining, transport, marine, logistics, agriculture, and manufacturing

- Commercially focused support with industry-specific product guidance

Stay updated with MultiTorque’s latest fire suppression solutions:

👉 LinkedIn

Conclusion: Industrial Fire Suppression Equipment That Performs

For operations that demand reliability, MultiTorque delivers fire suppression equipment built for harsh Australian environments. From FirePro aerosol suppression to Amerex extinguishers and complete suppression component supply, we equip businesses with the products needed to stay safe, compliant, and operational.

For orders or product enquiries:

📞 1300 726 525

📧 sales@multitorque.com