Mining sites across Australia deal with one common challenge: water. Whether it’s groundwater inflow, surface water intrusion, or slurry accumulation, every mine needs a robust and reliable dewatering solution. That’s where a quality dewatering pump mining system comes in.

At MultiTorque, we supply and support powerful dewatering pump solutions specifically tailored for mining operations. Built for the toughest jobs, our systems are designed to keep your pits dry, your equipment safe, and your production flowing without delay.

What Is a Dewatering Pump for Mining?

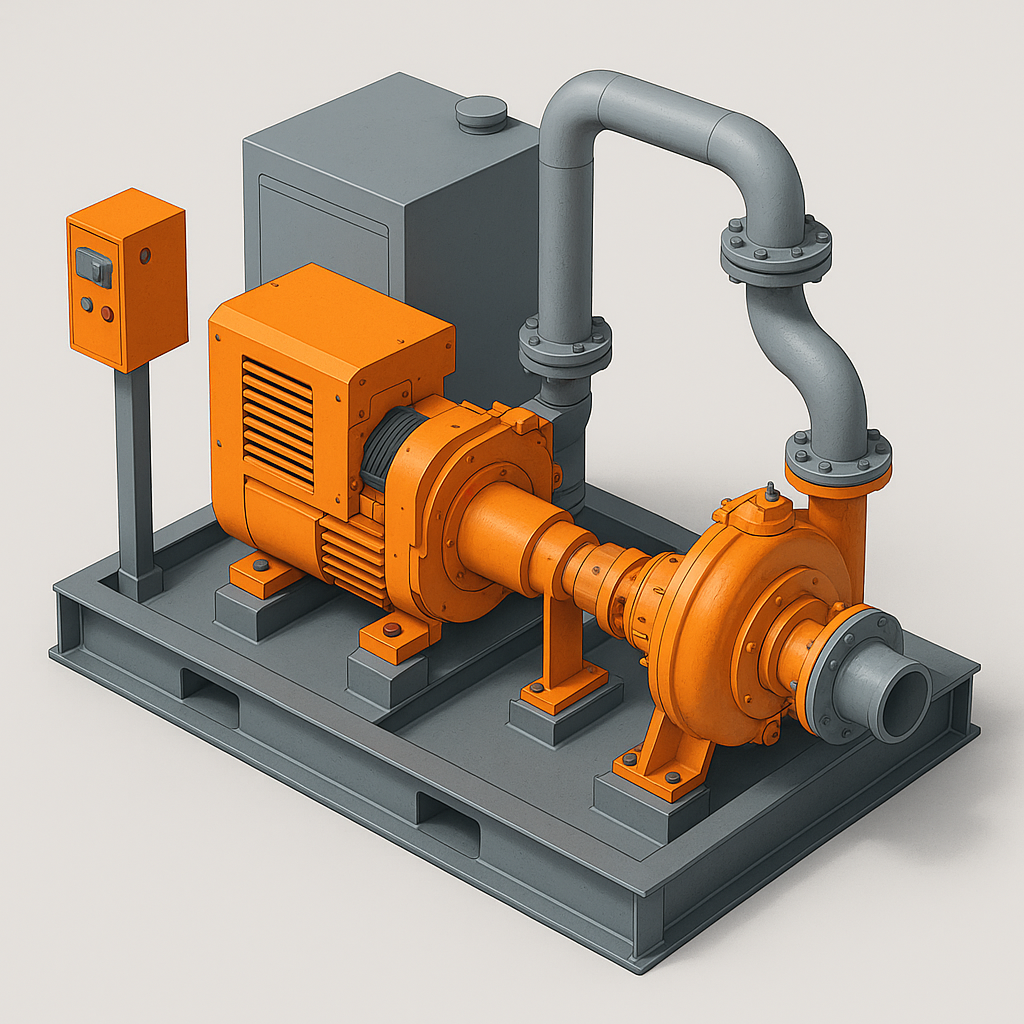

A dewatering pump mining system is a high-capacity pump setup designed to remove water from mine sites. These pumps manage water that collects in open pits, underground tunnels, tailings dams, and processing plants.

MultiTorque provides a range of mining-ready pump types, including:

- Diesel-driven centrifugal pumps

- Electric submersible dewatering pumps

- High-head vertical turbine pumps

- Slurry pumps for solids-laden water

- Custom-built trailer and skid-mounted systems

From shallow sump management to high-volume pit dewatering, we’ll match the pump to your site conditions and performance requirements.

Why Is Dewatering Essential in Mining?

Water is a constant threat to mine productivity. Without effective dewatering, operators face:

- Flooded pits and production stoppages

- Damaged machinery and safety hazards

- Poor working conditions for crew

- Erosion and instability of haul roads

- Delays in blasting, loading, and haulage

- Non-compliance with environmental standards

With the right dewatering pump mining setup, you gain control over groundwater and weather impacts, ensuring uninterrupted operations.

Where Are Mining Dewatering Pumps Used?

Our dewatering pump systems are deployed across:

- Open-pit coal and iron ore mines

- Gold and copper operations

- Underground decline dewatering

- Lithium and rare earth extraction sites

- Quarry and sand pit drainage

- Processing plant wastewater control

From the Pilbara to the Hunter, MultiTorque is trusted by mining contractors, site managers, and plant operators to keep things flowing.

Features of MultiTorque Dewatering Pumps

✔ High Flow & Head Capacity

Our mining pumps can move thousands of litres per minute, with options for deep pit dewatering and long-distance discharge.

✔ Durable Construction

Built with abrasion-resistant materials, hardened impellers, and heavy-duty seals to handle abrasive, corrosive, and solids-laden water.

✔ Flexible Mounting Options

Available as trailer-mounted, skid-based, or submersible systems to suit any mine layout or relocation need.

✔ Automated Control Options

We offer float switches, level sensors, and PLC integration for hands-free operation and reduced labour cost.

✔ Reliable Power Choices

Choose between diesel-powered units for off-grid work or electric motors for fixed installations with generator or mains supply.

Repairs, Parts, and Support

Downtime in mining costs more than just time—it costs productivity. That’s why MultiTorque offers full-service support including:

- Pump rebuilds and diagnostics

- Seal and impeller replacement

- Engine and motor servicing

- Emergency breakdown assistance

- Rapid dispatch of critical spare parts

Our service centres in Brisbane and Perth are backed by mobile techs who can get your gear back online fast.

Trusted Brands, Proven in Mining

We work with leading pump and engine brands such as:

- Napco

- Wilden

- NOV Mono

- Orbit

- Atlas Copco

- Kubota & Perkins diesel engines

These are names that mine operators across Australia trust—and so do we.

Why Choose MultiTorque?

✔ 15+ years in industrial and mining pump supply

✔ End-to-end support, from system design to servicing

✔ On-demand mobile service teams

✔ Heavy-duty, site-ready pump builds

✔ Custom fabrication and control system integration

We’re not just another supplier—we’re your on-the-ground pumping partner.

Let’s Get Your Site Pumping

If you need a dependable, high-performance dewatering pump mining system, MultiTorque delivers every time. From procurement and supply to service and support, we’ve got you covered—nationwide.

📞 Call 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

🔗 Connect with us on LinkedIn: MultiTorque LinkedIn

dewatering pump mining

dewatering pump mining

dewatering pump mining