A heavy duty starter is the backbone of every high-performance diesel and industrial engine system. Whether you’re running earthmoving equipment, mining haul trucks, oilfield rigs, or large agricultural machinery, your starter needs to deliver maximum torque under pressure—every single time.

At MultiTorque, we supply, repair, and maintain heavy duty starters across Australia. With 15+ years of experience and a reputation for precision workmanship and dependable service, we help industrial clients reduce downtime and get the job done—no matter how tough the terrain.

🔗 Visit MultiTorque Homepage

🔗 Connect on LinkedIn

What Is a Heavy Duty Starter?

A heavy duty starter is a high-torque motor designed to crank large engines used in commercial and industrial applications. These starters are built to handle the high compression ratios found in diesel engines, and they must operate reliably in harsh conditions such as heat, dust, cold, and vibration.

Heavy duty starters are commonly found in:

- Trucks and heavy haul vehicles

- Construction machinery (excavators, loaders, graders)

- Agricultural equipment (tractors, sprayers, harvesters)

- Oil & gas rigs and support vehicles

- Mining haul trucks and drill rigs

- Marine engines and generators

Types of Heavy Duty Starters

1. Electric Starters

Powered by a 12V or 24V battery, electric heavy duty starters are the most common. They are simple to operate and maintain and are ideal for trucks, buses, and general construction machinery.

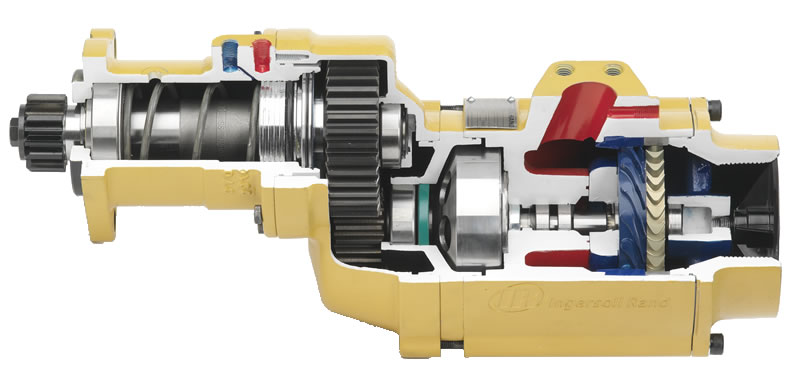

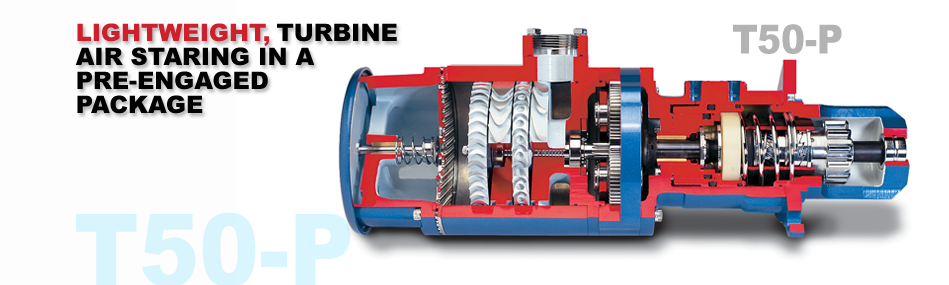

2. Pneumatic (Air) Starters

Used in explosive or hazardous environments, air starters use compressed air to crank engines. These are preferred in oil & gas, marine, and mining operations where spark-free equipment is essential.

3. Hydraulic Starters

Reliable and spark-free, hydraulic heavy duty starters are used in extremely remote or rugged environments. They’re compact and don’t rely on batteries or air tanks.

MultiTorque supplies all three types depending on your application and operating environment.

Why a Reliable Heavy Duty Starter Matters

When your starter fails, everything grinds to a halt. A reliable heavy duty starter ensures:

- Reduced Downtime: Keeps critical machines running on schedule

- Operational Safety: Prevents dangerous manual cranking or emergency workarounds

- Lower Maintenance Costs: A robust starter reduces stress on electrical and battery systems

- Cold Weather Performance: Essential for starting diesel engines in freezing conditions

- Fuel Efficiency: A fast, strong start means less idle time and more efficient operation

At MultiTorque, we help businesses stay one step ahead with proactive maintenance and top-tier replacement options.

Common Signs of Starter Trouble

A failing starter can usually be detected before it completely dies. Look out for:

- Clicking sound when trying to start the engine

- Slow or no crank when the ignition is turned

- Grinding or whining noises from the engine bay

- Intermittent starting

- Visible smoke or a burning smell

- Starter motor stays engaged after ignition

If you’re seeing these symptoms, it may be time to service or replace your heavy duty starter. MultiTorque offers fast diagnostics and full system checks.

Our Heavy Duty Starter Services

At MultiTorque, we offer a comprehensive range of services tailored to the needs of commercial and industrial operators:

✔ Starter Motor Supply

We stock high-quality starters for major engine brands including Cummins, Caterpillar, Detroit Diesel, Hino, Isuzu, Scania, and Volvo.

✔ Starter Rebuilds & Repairs

Our technicians can disassemble, clean, rebuild, and test your existing starter for a cost-effective solution.

✔ Custom Installations

We retrofit or replace starters on all types of industrial equipment, from single units to entire fleets.

✔ Preventative Maintenance

We perform voltage checks, pinion inspections, load tests, and connection reviews to catch problems before they happen.

Compatible Engine Types

Our heavy duty starters are compatible with a wide range of diesel and industrial engines:

- Cummins ISX, QSK, and B-series

- CAT C-series and 3400 engines

- Detroit Diesel Series 60 and DD15

- Volvo D-series

- Scania DC13 and DC16

- Perkins and Deutz diesel engines

- John Deere and Kubota industrial engines

Need help identifying the right starter? Contact our technical team—we’ll spec the perfect fit.

Benefits of Choosing MultiTorque

🛠 Expertise You Can Trust

With 15+ years in the industry, we’ve handled every starter type under the sun.

🚛 Nationwide Reach

From remote mining sites to urban fleets, we support clients across Perth, Brisbane, and beyond.

⚙️ Custom Starter Solutions

We provide tailored recommendations based on your environment, application, and engine type.

🔍 Quality Control

Every rebuild or supply unit goes through strict inspection and testing to ensure OEM performance.

👷 Client-First Service

Our team is fast, responsive, and focused on long-term client success—not just one-off sales.

How to Extend the Life of a Heavy Duty Starter

Want your starter to go the distance? Follow these pro tips:

- Maintain Battery Health – A weak battery increases current draw and stresses the starter.

- Clean Connections – Corrosion or loose cables reduce starting power.

- Avoid Over-Cranking – Continuous cranking can overheat and damage internal components.

- Listen for Changes – Catch problems early by noting grinding, whining, or stalling sounds.

- Routine Inspections – Schedule regular checks to catch wear before failure.

Ask us about starter motor servicing as part of your equipment maintenance plan.

Get a Heavy Duty Starter That Won’t Let You Down

If you need a heavy duty starter that performs in the harshest conditions, MultiTorque is your go-to partner. We understand the pressure of keeping equipment running—and we deliver fast.

📞 Call now: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: www.multitorque.com.au

🔗 LinkedIn: MultiTorque Industries