In the world of fluid handling, accuracy is everything. Whether you’re working with chemicals, water treatment, or food-grade substances, precision dosing ensures safety, compliance, and cost-efficiency. That’s where the electronic metering pump shines. These technologically advanced pumps have revolutionized fluid dosing, bringing automation, control, and accuracy to the forefront.

At MultiTorque, we specialise in supplying reliable, high-quality fluid handling systems, including electronic metering pumps tailored to suit diverse industries across Australia.

What Is an Electronic Metering Pump?

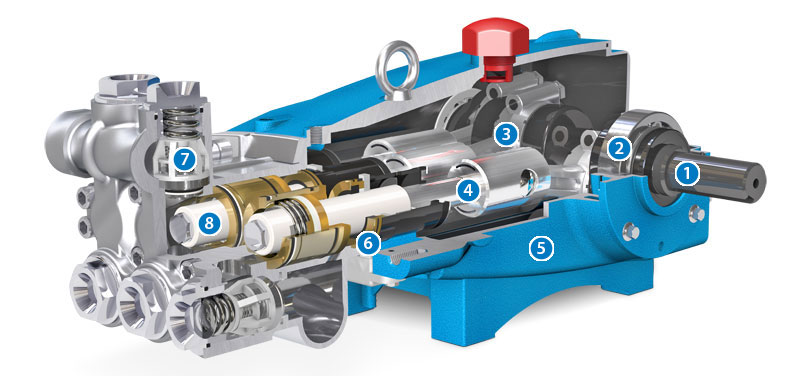

An electronic metering pump is a type of positive displacement pump designed to deliver precise amounts of fluid. It’s electronically controlled, often programmable, and typically used in applications that require exact dosing of liquids over time.

These pumps are essential in water treatment, agriculture, food processing, chemical manufacturing, and more. They usually consist of a pump head, a control panel or interface, a drive mechanism, and a motor. Unlike manual or mechanical metering pumps, the electronic version integrates sensors and controllers to ensure exact dosing, often to fractions of a millilitre.

How Electronic Metering Pumps Work

Electronic metering pumps use a solenoid or stepper motor that pulls back and pushes a diaphragm within the pump head. When the diaphragm retracts, liquid is drawn in through a check valve. When it pushes forward, the fluid is dispensed through the discharge valve.

Thanks to electronic control, these pumps can be programmed for:

- Flow rate (litres per hour or ml per cycle)

- Injection frequency

- Batch dosing

- Pulse or analogue input responsiveness

This level of control ensures reliability in high-stakes environments where human error or mechanical inconsistency can be costly or dangerous.

Applications of Electronic Metering Pumps

Electronic metering pumps are used in countless industries across Australia, including:

- Water Treatment Plants: Dosing chlorine, pH balancing chemicals, or coagulants.

- Agriculture: Controlled delivery of fertilisers, pesticides, and soil conditioners.

- Food & Beverage: Accurate dosing of flavours, preservatives, or cleaning chemicals.

- Chemical Processing: Metering acids, alkalis, and specialty chemicals.

- Pharmaceuticals: Dispensing active ingredients or sterile solutions.

- Mining: Injection of reagents in mineral extraction and wastewater treatment.

MultiTorque supports a broad range of industries and can source or custom-configure an electronic metering pump suited to your needs.

Benefits of Using an Electronic Metering Pump

- High Precision: Deliver exact volumes with minimal deviation.

- Programmable: Easily adjust settings for batch dosing, frequency, and flow rate.

- Compact and Modular: Saves space and integrates easily into existing systems.

- Durability: Built for demanding environments with chemical-resistant materials.

- Safety: Minimises human contact with hazardous chemicals.

- Cost-Effective: Reduces chemical wastage and operational downtime.

- Automation-Ready: Many models connect to SCADA or PLC systems for smart facility integration.

Key Features to Consider

When selecting an electronic metering pump, it’s important to evaluate your specific needs. MultiTorque offers guidance and technical support to help you select the right pump, but here are a few features to consider:

- Flow Rate Range: Ensure the pump meets your minimum and maximum dosing needs.

- Material Compatibility: Choose from PVDF, stainless steel, PTFE, or polypropylene, depending on the fluid.

- Control Inputs: Some models support 4-20mA, pulse, or manual settings.

- Accuracy Tolerance: Look for pumps with ±1% or better.

- Duty Cycle: Is it continuous or intermittent? This affects motor type and cooling needs.

- Mounting & Enclosure: Wall, foot, or panel mounting options with IP-rated enclosures.

Why Choose MultiTorque for Electronic Metering Pumps?

MultiTorque has over 15 years of industry experience supplying pumps and engineered fluid systems across Australia. We work with trusted manufacturers to offer electronic metering pumps that are built to last, even in the toughest environments.

Here’s why clients trust us:

- Extensive Range: From entry-level pumps to fully integrated PLC-compatible dosing systems.

- Custom Solutions: We offer tailored setups based on your specific operational needs.

- Technical Support: Get help with installation, maintenance, and system optimisation.

- In-House Repairs: We don’t outsource. All pump repairs are completed by our own expert team.

- Fast Turnaround: Local stock and efficient procurement mean less downtime.

- Nationwide Reach: From Perth to Brisbane, we serve industrial clients all across Australia.

Explore our full product range at www.multitorque.com.au.

Maintenance Tips for Longevity

To get the most out of your electronic metering pump, follow these basic tips:

- Regular Inspection: Check diaphragms, seals, and valves monthly.

- Flush System: Run clean water through the system after dosing aggressive chemicals.

- Calibrate Frequently: Particularly if your process relies on strict dosing compliance.

- Monitor Input Signals: Verify that pulses or analogue signals are consistent.

- Clean Filters and Lines: Prevent clogging that can compromise dosing accuracy.

We also offer maintenance guides and service kits for most major brands.

Brands We Work With

We supply or source from industry-trusted brands such as:

- Prominent

- LMI Milton Roy

- SEKO

- Grundfos DDA/DDE

- Blue-White

- Pulsafeeder

If you have a preferred brand or require cross-compatibility with existing systems, we’ll source the right components.

Final Thoughts

The electronic metering pump is a game-changer in any operation that values precision, efficiency, and reliability. Whether you’re dealing with chemical dosing, water treatment, or industrial automation, having the right pump system in place can drastically improve performance and safety.

At MultiTorque, we offer unmatched expertise in pump supply and aftersales support. Let us help you upgrade your dosing systems with high-performance electronic metering pumps tailored to your business.

Get in Touch

📞 Call MultiTorque on 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: https://www.multitorque.com.au

🔗 LinkedIn: https://www.linkedin.com/company/multitorque-industries