When it comes to industrial pumps in Brisbane, businesses across mining, construction, agriculture, and manufacturing know how crucial reliability is. A failed pump can bring entire operations to a halt, costing both time and money. That’s why choosing the right partner for pump supply, servicing, and repair makes all the difference.

📞 Call us today on 1300 726 525

📧 Email us at sales@multitorque.com

MultiTorque has built its reputation as a trusted provider of industrial pumps across Australia, with a strong presence in Brisbane and surrounding regions. With more than 15 years of industry experience, we focus on supplying high-quality pump brands, providing in-house repairs, and tailoring solutions for unique industrial applications.

📞 Call us today on 1300 726 525

📧 Email us at sales@multitorque.com

Why Industrial Pumps Are Essential for Brisbane Industries

Brisbane’s economy is driven by diverse sectors, including mining in Queensland’s resource-rich areas, food and beverage processing, agriculture, water treatment, and construction. Each of these industries relies heavily on pumps to keep operations running smoothly.

Industrial pumps are used to:

- Transfer water, slurry, and chemicals efficiently

- Handle abrasive materials in mining and quarrying

- Maintain consistent flow in food and beverage production

- Support irrigation systems for agriculture

- Power dewatering systems on construction sites

Without dependable industrial pumps, businesses risk equipment failure, product delays, and safety hazards. That’s why maintenance and repair are just as important as supply.

MultiTorque’s Expertise with Industrial Pumps in Brisbane

MultiTorque provides both supply and workshop repair services for a wide range of industrial pumps in Brisbane. We understand that every site has unique requirements, and our experienced team is ready to assist with the right solution.

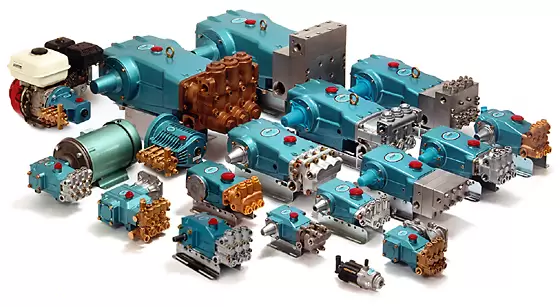

1. Pump Supply from Leading Brands

We work with leading global pump manufacturers, including:

- Wilden – trusted for air-operated double diaphragm pumps

- NOV Mono – well-known for progressive cavity pumps

- Orbit – durable designs for industrial use

- Napco – efficient and versatile pumping systems

By sourcing directly from trusted manufacturers, we ensure customers receive pumps that are reliable, cost-effective, and built to last.

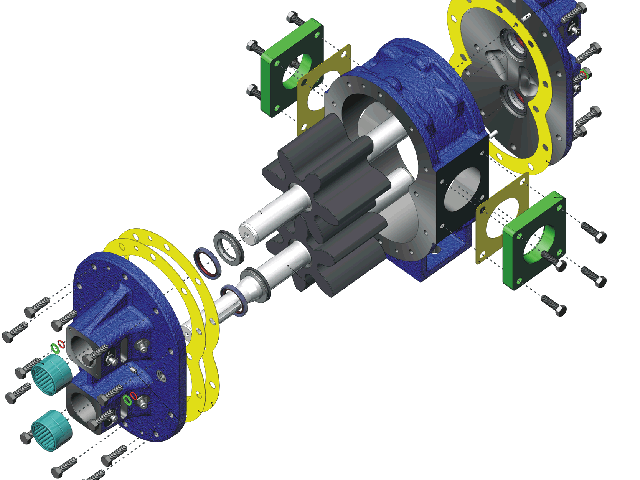

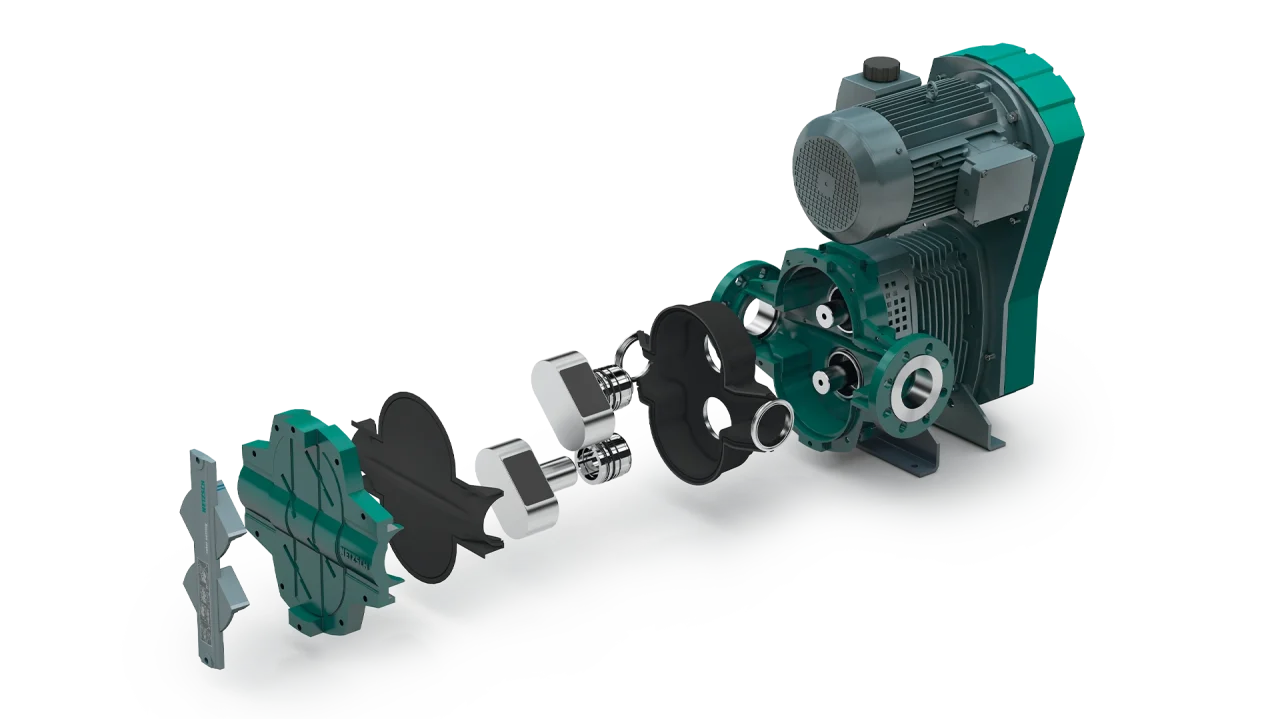

2. In-House Pump Repairs

Unlike some providers, MultiTorque does not offer on-site repairs — instead, we operate fully equipped workshops where pumps can be stripped, inspected, and rebuilt under controlled conditions. This allows us to maintain strict safety and quality standards while ensuring every repair meets manufacturer specifications.

3. Custom Pumping Solutions

MultiTorque also provides custom engineering support, such as skid-mounted pump systems and borehole pump trailers, designed and built for specific client needs. Brisbane industries often require bespoke equipment, and our workshop teams deliver practical solutions to keep operations moving.

Types of Industrial Pumps We Work With

Different industries in Brisbane use a wide variety of pump types. MultiTorque’s expertise covers:

- Centrifugal Pumps – commonly used for water transfer and industrial fluids.

- Progressive Cavity Pumps – ideal for viscous fluids and slurries.

- Air Operated Double Diaphragm (AODD) Pumps – reliable for chemical handling and harsh applications.

- Submersible Pumps – designed for dewatering in construction and mining.

- Borehole Pumps – perfect for groundwater supply in agricultural and industrial use.

This wide coverage ensures that no matter what your industry requires, MultiTorque can assist.

📞 Call us today on 1300 726 525

📧 Email us at sales@multitorque.com

Industrial Pump Repairs Brisbane

For businesses in Brisbane, keeping equipment reliable is just as important as sourcing new pumps. At MultiTorque, we provide industrial pump repair services backed by skilled technicians and years of hands-on experience.

Our workshop process includes:

- Detailed Inspections – identifying wear, corrosion, or mechanical damage.

- Component Replacement – sourcing genuine pump parts, including seals, bearings, rotors, and casings.

- Testing and Certification – ensuring pumps operate safely before being returned to service.

- Preventative Maintenance Programs – reducing the likelihood of unexpected breakdowns.

We know downtime costs money. That’s why our goal is always to deliver fast, reliable repairs without compromising quality.

Why Choose MultiTorque in Brisbane?

When searching for industrial pumps Brisbane, it’s important to choose a supplier that goes beyond just selling equipment. MultiTorque’s difference lies in:

- 15+ years of industry expertise

- Strong relationships with global pump brands

- In-house workshop repairs for controlled quality

- Custom pump engineering solutions tailored to Brisbane industries

- Long-term client support built on reliability and trust

Our team doesn’t just sell pumps — we partner with businesses to ensure equipment works reliably over the long haul.

Supporting Brisbane’s Industrial Growth

Brisbane continues to expand as a hub for manufacturing, construction, and resource industries. With this growth comes increasing demand for durable and efficient pumping systems.

From mine dewatering pumps to food-grade fluid transfer systems, MultiTorque provides equipment that helps local industries thrive. By supplying, repairing, and customizing industrial pumps, we support Brisbane businesses in achieving higher efficiency, lower downtime, and greater reliability.

Get in Touch with MultiTorque

If you’re looking for dependable industrial pumps in Brisbane — whether for supply, repair, or custom solutions — MultiTorque is ready to help.

📞 Call us today on 1300 726 525

📧 Email us at sales@multitorque.com

Visit our website at www.multitorque.com.au for more details.

Connect with us on LinkedIn for updates and industry insights.

Conclusion

The demand for industrial pumps in Brisbane continues to rise as industries grow and diversify. From mining and water treatment to agriculture and manufacturing, reliable pumping systems form the backbone of daily operations.

With decades of experience, access to trusted brands, and workshop repair capabilities, MultiTorque stands as Brisbane’s go-to partner for pump supply and servicing. Whether you need a brand-new pump or reliable repairs, our team ensures your equipment delivers long-term performance.

Choose MultiTorque for your industrial pump needs in Brisbane — because when it comes to reliability, we don’t just deliver parts, we deliver peace of mind.

Industrial Pumps Brisbane

Industrial Pumps Brisbane

Industrial Pumps Brisbane

Industrial Pumps Brisbane

Industrial Pumps Brisbane Industrial Pumps Brisbane Industrial Pumps Brisbane