Marine Fire and Safety – Protecting Vessels and Critical Marine Assets

Marine fire and safety is a critical requirement for vessels, ports, offshore assets, and marine-based infrastructure operating in harsh and high-risk environments. Fire incidents at sea or in port facilities can escalate rapidly due to confined spaces, electrical systems, fuel sources, and limited emergency response access.

MultiTorque Fire Suppression supplies proven marine fire and safety solutions designed to protect people, vessels, and high-value marine equipment while meeting Australian standards and operational demands.

Check out the marine fire range here: https://fsequip.au/

📞 Call: 1300 726 525

📧 Email: sales@multitorque.com

Why Marine Fire and Safety Is Critical

Marine environments present unique fire risks that differ significantly from land-based facilities. These include:

- Confined engine rooms and electrical compartments

- Flammable fuels and hydraulic systems

- Salt exposure causing corrosion and electrical faults

- Continuous vibration and mechanical stress

- Limited evacuation and firefighting access

Effective marine fire and safety systems must be compact, corrosion-resistant, fast-acting, and reliable in both manned and unmanned spaces.

Marine Fire and Safety Solutions Supplied by MultiTorque

MultiTorque supplies a wide range of marine fire and safety equipment suitable for commercial vessels, workboats, ports, and offshore applications.

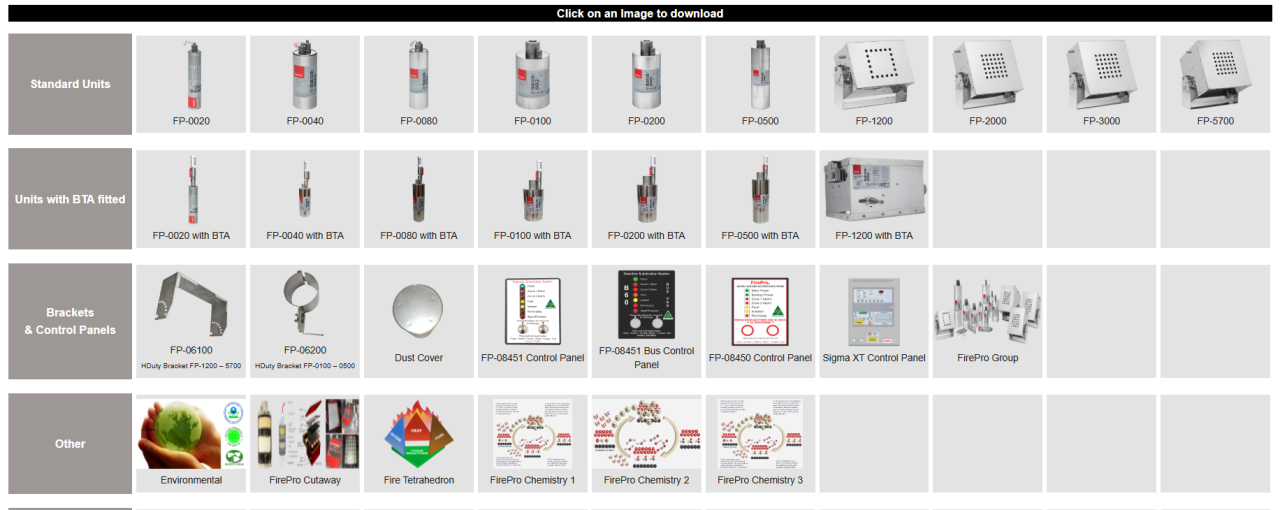

Aerosol Fire Suppression for Marine Applications

Condensed aerosol fire suppression systems are ideal for marine environments due to their compact size and minimal infrastructure requirements. These systems are commonly used to protect:

- Engine rooms

- Electrical switchboards

- Control cabinets

- Battery compartments

- Generator enclosures

Aerosol fire suppression systems work by interrupting the chemical combustion process, providing fast fire knockdown without water, foam, or high-pressure gas cylinders.

Marine Fire Extinguishers

MultiTorque supplies marine-rated fire extinguishers suitable for:

- Engine and machinery spaces

- Accommodation areas

- Electrical rooms

- Deck and cargo areas

Available extinguisher types include dry chemical, CO₂, and clean agent options designed for marine compliance and durability.

Electrical and Equipment Fire Protection

Marine vessels rely heavily on electrical systems, making electrical fire protection essential. Fire protection solutions are available for:

- Switchboards and control panels

- Navigation and communication systems

- Lithium-ion battery installations

- Shore power connections

Clean-agent and aerosol-based systems help protect sensitive electronics without damaging critical equipment.

You can view available marine fire suppression and safety products supplied by MultiTorque Fire Suppression at https://fsequip.au/, where certified solutions are available for a wide range of marine and offshore applications.

Certified Marine Fire and Safety Compliance

Marine fire and safety equipment supplied by MultiTorque aligns with relevant Australian standards and marine industry requirements, including:

- AS 4487 – Condensed Aerosol Fire Extinguishing Systems

- AS 5062 – Fire Protection for Mobile and Transportable Equipment

These standards support the use of aerosol and compact fire suppression systems in vessels, mobile plant, and transport-related marine assets.

Typical Marine Fire and Safety Applications

MultiTorque marine fire and safety solutions are commonly used across:

- Commercial vessels and workboats

- Tugboats and pilot vessels

- Fishing fleets

- Port and wharf infrastructure

- Offshore platforms and barges

- Marine generators and pump rooms

- Battery and hybrid propulsion systems

Whether protecting a single engine compartment or a fleet of marine assets, reliable fire protection is essential for operational continuity and crew safety.

Advantages of Modern Marine Fire and Safety Systems

Compared to traditional water-based systems, modern marine fire and safety solutions offer:

- No water damage to engines or electronics

- Reduced corrosion risk

- Compact, space-saving installation

- Faster fire suppression response

- Lower maintenance requirements

These advantages make aerosol and clean-agent fire protection particularly suitable for marine environments where space and reliability are critical.

Why Choose MultiTorque for Marine Fire and Safety?

MultiTorque is an Australian supplier with deep experience supporting industrial, transport, marine, and offshore sectors. Through MultiTorque Fire Suppression, customers gain access to reliable marine fire and safety equipment backed by industry knowledge and proven products.

MultiTorque offers:

- Certified marine fire and safety solutions

- Supply support across Australia and New Zealand

- Equipment suitable for harsh marine conditions

- Long-term asset protection and compliance support

Learn more about MultiTorque’s broader industrial and safety capabilities by visiting:

https://www.multitorque.com.au/

Speak to MultiTorque Fire Suppression

If you’re looking to upgrade or install reliable marine fire and safety solutions for vessels, ports, or offshore assets, MultiTorque Fire Suppression can assist.

📞 Call: 1300 726 525

📧 Email: sales@multitorque.com

For projects, updates, and marine safety insights, connect with MultiTorque on LinkedIn:

https://www.linkedin.com/company/3176927