Xylem Dewatering In industries where water management is critical—such as mining, construction, oil and gas, and municipal works—choosing the right dewatering system can make or break operational success. Flooded work areas, groundwater seepage, and stormwater events are more than just inconveniences; they can bring entire projects to a halt, increase costs, and create safety hazards. That’s why dependable, efficient dewatering equipment is a must-have.

Among the world’s most respected names in pumping technology is Xylem, a global leader in water technology. Their dewatering pumps, particularly those under the Godwin and Flygt brands, have earned a reputation for reliability, versatility, and high performance in tough environments.

At MultiTorque, we specialize in supplying, servicing, and repairing a wide range of pumps, including Xylem’s dewatering solutions, across Australia. With more than 15 years of industry expertise, our team has built strong partnerships with businesses that need equipment they can trust—backed by support that goes the distance.

📞 Call us on 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit us at www.multitorque.com.au

🔗 Connect with us on LinkedIn

What is Xylem Dewatering?

Xylem dewatering refers to the company’s comprehensive range of pumps and systems designed to move water safely and efficiently from one location to another. These solutions cover everything from removing groundwater at a construction site to handling wastewater in municipal applications.

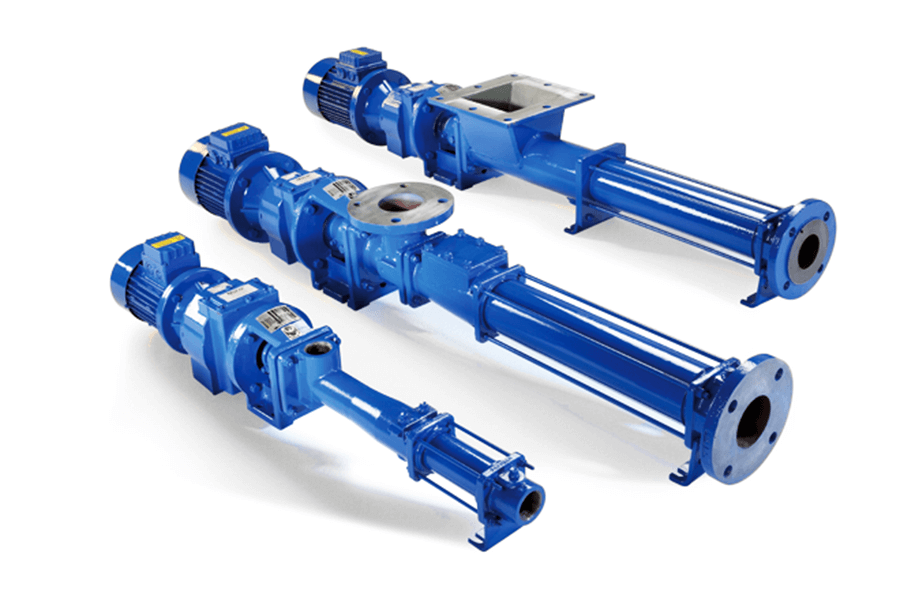

Some of the most recognized Xylem dewatering brands include:

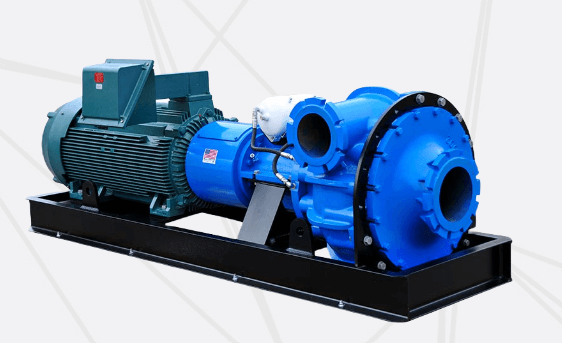

- Godwin Dri-Prime® Pumps – Diesel-driven, automatic priming pumps designed for challenging dewatering tasks.

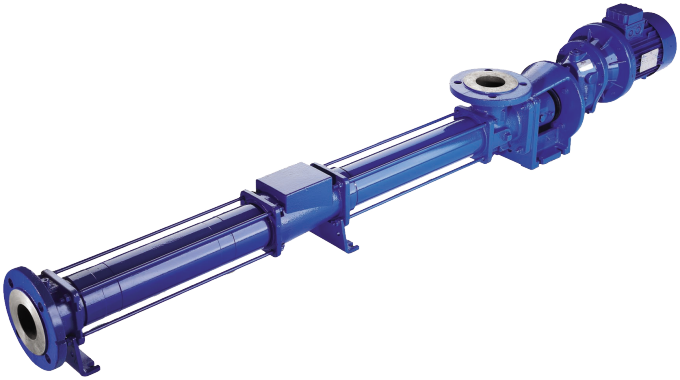

- Flygt Submersible Pumps – Heavy-duty submersibles built for long-lasting performance in flooded or submerged environments.

- Heidra Hydraulic Submersibles – Pumps powered by hydraulic systems, ideal for situations where traditional diesel-driven units can’t be used.

Together, these products deliver a versatile suite of solutions for industries facing water management challenges.

Applications of Xylem Dewatering Pumps

The strength of Xylem’s range lies in its ability to handle diverse applications. At MultiTorque, we’ve supported Australian businesses across a wide range of projects where Xylem dewatering pumps are the right tool for the job:

- Mining operations – Keeping haul roads, pits, and quarries dry to maintain safe working conditions.

- Construction projects – Managing groundwater during excavations, tunnels, and foundation works.

- Municipal infrastructure – Handling sewage bypasses, stormwater pumping, and wastewater treatment.

- Emergency flood response – Rapidly deploying pumps to remove floodwater and protect communities.

- Industrial processes – Supporting chemical plants, refineries, and manufacturing facilities that need reliable water transfer.

Wherever water needs to be moved, Xylem has a solution—and MultiTorque ensures those solutions perform reliably in the field.

Why MultiTorque is the Right Partner for Xylem Dewatering in Australia

1. 15+ Years of Industry Expertise

MultiTorque has been working with pumps and dewatering equipment for more than 15 years. Our team understands the challenges faced in Australia’s demanding industries, from the red dust of the Pilbara to Queensland’s storm-prone worksites. When you choose us, you’re working with professionals who know how to keep your operations moving.

2. Supply of Xylem Dewatering Pumps

Looking for new equipment? MultiTorque supplies a wide range of pumps, including Xylem’s Godwin and Flygt series. Whether you need a rugged diesel-driven pump for a remote site or a submersible unit for continuous operation, we’ll help you find the right model for your requirements.

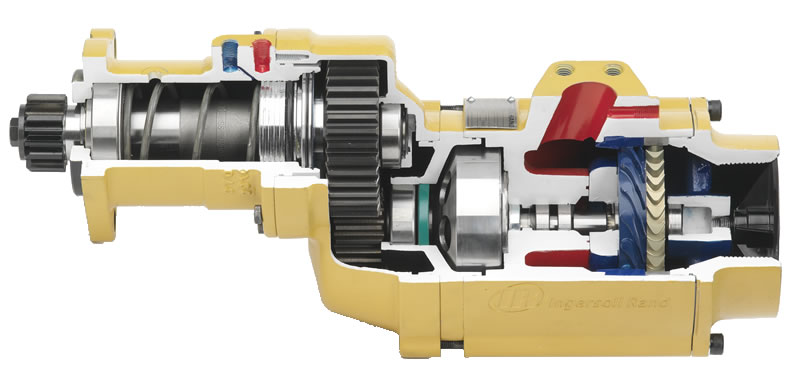

3. In-House Workshop Repairs

MultiTorque specializes in workshop-based repairs. This allows us to deliver consistent, high-quality servicing under controlled conditions. We don’t stretch ourselves thin with on-site callouts; instead, we focus on delivering reliable, thorough overhauls and part replacements that ensure your pumps perform like new.

4. Parts Sourcing Made Simple

Downtime costs money. That’s why we prioritize fast and efficient parts sourcing. From impellers and wear plates to seals and gaskets, MultiTorque ensures you get the genuine or compatible parts you need to keep your Xylem dewatering equipment operational.

5. Custom Engineering Solutions

MultiTorque doesn’t just supply off-the-shelf pumps—we also engineer custom pump trailers and setups to match unique project requirements. If your site has specific challenges, we’ll work with you to design a solution that maximizes efficiency and safety.

6. Nationwide Reach

With branches in Perth and Brisbane, MultiTorque supports clients across Australia. No matter where your operation is located, we can provide the right equipment and servicing.

Features that Make Xylem Dewatering Pumps Stand Out

So, what makes Xylem dewatering pumps such a trusted choice worldwide?

- Automatic priming technology – Godwin’s Dri-Prime® system allows pumps to start and restart automatically, even from dry.

- Solids-handling capability – Pumps like the CD series can handle large solids without clogging.

- High performance – Reliable flow rates and head pressures for demanding tasks.

- Rugged durability – Built with corrosion-resistant materials to withstand harsh conditions.

- Smart technology – Many pumps include telemetry and monitoring for efficiency and preventative maintenance.

This blend of innovation and durability ensures operators can focus on the job at hand rather than worrying about pump failures.

Maintenance Tips for Xylem Dewatering Equipment

Keeping your equipment in top shape is essential for reliability. At MultiTorque, we recommend:

- Regular inspections – Monitor impellers, seals, and wear parts for damage.

- Engine servicing – For diesel-driven pumps, follow the engine manufacturer’s guidelines for oil and filter changes.

- Fuel management – Ensure clean diesel and replace filters as needed.

- Lubrication – Keep bearings properly lubricated to prevent premature wear.

- Workshop servicing – Schedule periodic professional overhauls at MultiTorque to minimize costly breakdowns.

MultiTorque: Built on Reliability and Safety

At MultiTorque, our values are simple: reliability, safety, and long-term relationships. We know our clients depend on their pumps for mission-critical tasks, and we take that responsibility seriously. When you choose us for Xylem dewatering solutions, you’re choosing a partner committed to delivering results you can depend on.

Whether you need new equipment, urgent repairs, or a custom-built solution, MultiTorque is ready to help.

Connect with MultiTorque

If your project requires dependable dewatering, it’s time to partner with the experts at MultiTorque. We’ll help you find the right Xylem dewatering pump, maintain it for peak performance, and keep your operation running smoothly.

📞 Call us on 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit us at www.multitorque.com.au

🔗 Connect with us on LinkedIn

Conclusion

Water management is one of the most critical challenges in mining, construction, municipal, and industrial projects. With Xylem dewatering pumps, businesses gain access to some of the most reliable and versatile solutions available today. But equipment is only part of the equation—what you need is a partner who can supply, service, and support that equipment with expertise and dedication.

That’s where MultiTorque comes in. With 15+ years of experience, national reach, and a reputation for reliability, we are Australia’s trusted supplier and service partner for pumps like Xylem’s Godwin and Flygt series. From sourcing to servicing, MultiTorque ensures your pumps work as hard as you do.

Choose MultiTorque for your Xylem dewatering needs—and experience the difference a dedicated, reliable partner can make.