In industries where reliability, efficiency, and cost-effectiveness are non-negotiable, the Mono Jet Pump has emerged as a dependable solution. Known for its simple design and versatile performance, this pump type is widely used across agriculture, mining, dewatering, and general water transfer applications. MultiTorque, with over 15 years of pump expertise, supplies, services, and repairs a wide range of pumps—including the Mono Jet Pump—providing businesses across Australia with solutions they can trust.

For more information on Mono Jet Pumps or to request a service, contact MultiTorque today at 1300 726 525 or email sales@multitorque.com. You can also visit our website at www.multitorque.com.au and connect with us on LinkedIn.

In this article, we’ll explore what a Mono Jet Pump is, its benefits, key applications, and why partnering with MultiTorque ensures long-term operational success.

What is a Mono Jet Pump?

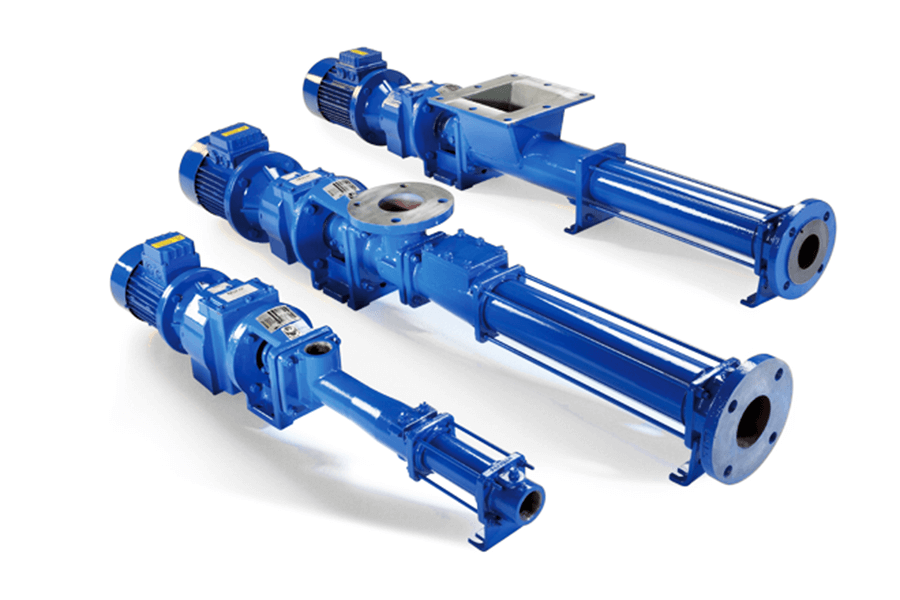

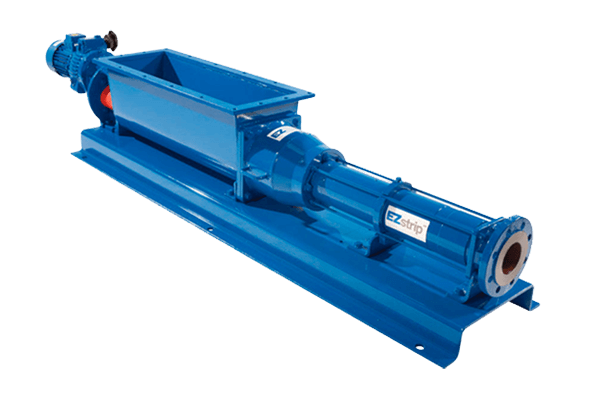

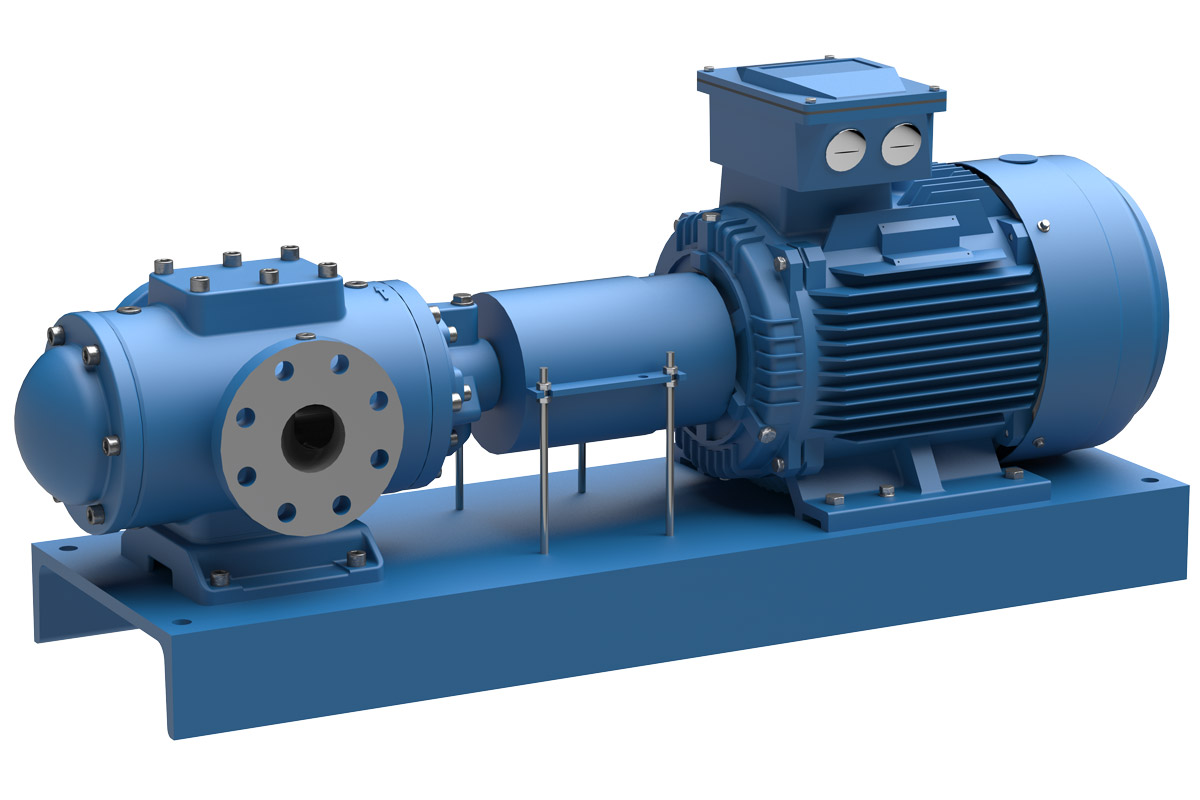

A Mono Jet Pump is a positive displacement pump designed to transfer fluids with minimal pulsation and excellent efficiency. Unlike centrifugal pumps that rely on high-speed impellers, Mono Jet Pumps use a helical rotor and stator system, enabling them to handle a variety of liquids—including abrasive, viscous, and solid-laden fluids—without significant wear.

This pump’s robust construction makes it ideal for environments where reliability and reduced downtime are essential. Its versatility has led to widespread adoption in both light-duty and heavy-duty applications.

Key Benefits of a Mono Jet Pump

The Mono Jet Pump is valued for a range of operational benefits that make it a preferred choice for many industries:

1. Durability in Harsh Conditions

Built from high-quality materials, Mono Jet Pumps can withstand abrasive fluids, ensuring longer service life and lower replacement costs.

2. High Efficiency

With its positive displacement mechanism, the pump delivers a consistent flow rate even under variable pressures, making it highly energy-efficient.

3. Low Maintenance

Fewer moving parts and a simple design translate to reduced maintenance requirements, minimizing downtime for industrial operators.

4. Versatility

Capable of handling everything from clean water to thick slurries, Mono Jet Pumps are adaptable across industries such as agriculture, mining, and wastewater treatment.

5. Cost-Effectiveness

Thanks to efficiency and longevity, the Mono Jet Pump often delivers a lower total cost of ownership compared to other pump types.

Common Applications of the Mono Jet Pump

The Mono Jet Pump is used in a variety of industries where fluid transfer efficiency is crucial. Some common applications include:

- Agriculture – Ideal for irrigation systems, livestock watering, and crop spraying.

- Mining – Handles abrasive slurries, tailings, and groundwater dewatering.

- Wastewater Management – Transfers sludge and other semi-solid waste materials efficiently.

- Food and Beverage – Moves viscous liquids like syrups and pastes with minimal damage to the product.

- General Industry – Used in water supply, pressure boosting, and fluid circulation systems.

This wide range of applications showcases the adaptability of the Mono Jet Pump, making it a strong investment for operators across multiple sectors.

Mono Jet Pump vs Other Pump Types

When choosing the right pump for your application, it’s helpful to compare the Mono Jet Pump to other commonly used pump types.

- Mono Jet Pump vs Centrifugal Pump: Centrifugal pumps work best for high-flow, low-viscosity fluids. Mono Jet Pumps excel in handling thicker, abrasive fluids with consistent flow, even under pressure.

- Mono Jet Pump vs Diaphragm Pump: While diaphragm pumps are good for chemical handling and precise dosing, Mono Jet Pumps provide greater durability and efficiency for continuous heavy-duty operations.

- Mono Jet Pump vs Screw Pump: Screw pumps, such as the Allweiler Screw Pump, are also reliable for viscous fluids. However, Mono Jet Pumps often provide more cost-effective solutions in agricultural and wastewater contexts.

This comparison highlights how the Mono Jet Pump fits as a versatile, all-round performer, especially in industries that require reliability and cost-efficiency.

MultiTorque: Your Trusted Pump Partner

For over 15 years, MultiTorque has been supplying and servicing pumps across Australia, with branches in both Perth and Brisbane. Our expertise covers a wide range of pump technologies, including:

- Mono MS Pumps

- Mono X Pumps

- Electric Diaphragm Water Pumps

- Yamada Air Pumps

- Graco Husky Pumps and Rebuild Kits

Unlike many competitors, MultiTorque does not just sell pumps—we also service and repair them in-house. Our technicians provide reliable workshop repairs, using OEM or high-quality aftermarket parts to restore pumps to peak performance.

Whether you’re seeking a new Mono Jet Pump for your operation or require expert servicing of your existing system, MultiTorque has the knowledge, tools, and experience to deliver results you can count on.

Why Choose MultiTorque for Your Mono Jet Pump?

- Proven Expertise – With over 15 years in the industry, we understand the complexities of pump systems across multiple sectors.

- Comprehensive Services – From supply to repair, we handle everything under one roof.

- Quality Assurance – We only use reliable parts, ensuring maximum performance and longevity.

- Nationwide Reach – With locations in Perth and Brisbane, we support businesses across Australia.

- Customer-Focused – Our long-term client relationships are built on trust, reliability, and safety.

Conclusion

The Mono Jet Pump is an essential solution for industries that demand efficiency, durability, and adaptability. Whether used in agriculture, mining, wastewater, or general fluid transfer, its ability to handle a wide range of fluids with minimal maintenance makes it an excellent investment.

At MultiTorque, we pride ourselves on supplying, servicing, and repairing pumps like the Mono Jet Pump to keep Australian industries running smoothly. With our extensive expertise and customer-first approach, we ensure every client receives reliable support and long-term solutions.

For more information on Mono Jet Pumps or to request a service, contact MultiTorque today at 1300 726 525 or email sales@multitorque.com. You can also visit our website at www.multitorque.com.au and connect with us on LinkedIn.