When it comes to safe, reliable, and low-maintenance water handling, air pump water solutions are a smart choice for many industries. Powered by compressed air rather than electricity, these systems excel in tough environments where power supply is inconsistent or where safety is a concern—such as explosive or wet areas.

At MultiTorque, we supply and support a range of air-powered water pumps across Australia for clients in mining, agriculture, oil & gas, wastewater, and beyond. Whether you’re transferring greywater, dewatering pits, or handling corrosive liquids, our air pump systems are engineered for dependable, hands-off performance.

What Is an Air Pump Water System?

An air pump water solution uses compressed air to power the movement of water or other liquids—typically through an air-operated diaphragm pump or similar positive displacement design. These pumps work by alternately pressurising air chambers to drive flexible diaphragms, which draw in and discharge liquid.

They’re ideal for water transfer in hazardous environments or where electricity isn’t readily available.

Benefits of Air-Powered Water Pumps

✅ Safe for Hazardous Locations

No electric motor means no risk of sparks—making these pumps ideal for flammable, explosive, or wet environments.

✅ Self-Priming

Air-operated diaphragm pumps can self-prime even with dry suction lifts of several metres, making them perfect for dewatering or remote water collection.

✅ Run-Dry Tolerant

Many air pumps can safely run dry without damage, reducing risk during operation and extending equipment life.

✅ Handles Dirty and Abrasive Water

Air pumps are highly effective for slurries, muddy water, and waste liquids. They’re commonly used in industrial sumps, pits, and construction sites.

✅ Compact and Portable

With no wiring or electrical panels, these pumps are easy to move between locations, mount to trailers, or use in mobile dewatering units.

Common Applications for Air Pump Water Solutions

🏗️ Construction and Mining

Used for dewatering pits, trenches, and sumps—particularly where electrical safety is a concern or where the water contains grit and debris.

💧 Wastewater and Treatment Plants

Ideal for chemical dosing, sludge transfer, and handling of greywater and caustics.

🌾 Agriculture and Irrigation

Portable and rugged enough for effluent transfer, tank draining, or stock water management in remote areas.

🛢️ Oil & Gas

Used in hazardous zones for pumping waste liquids, wash-down water, and fuel-contaminated slurries.

MultiTorque’s Air Pump Capabilities

We carry and support a variety of air-powered water pump types, including:

🔸 Double Diaphragm Pumps

Robust, versatile, and capable of pumping everything from clean water to sludge. We stock and service brands like Wilden, Yamada, and Tapflo.

🔸 Piston Air Pumps

High-pressure air-driven piston pumps for specialty applications such as vertical lifting or water blasting systems.

🔸 Custom Trailer or Skid Builds

Need mobility? We can mount air pumps on trailers or skids, complete with air hose reels, tank connections, and isolation valves—ready for rapid deployment.

🔸 Air System Integration

We help clients select compatible compressors, airlines, and fittings to ensure their system is ready to go on-site.

Why Choose MultiTorque?

We don’t just supply pumps—we provide complete air pump water solutions designed around your site needs, flow requirements, and environmental conditions. From basic sump dewatering to integrated multi-pump systems, we’ll work with you to ensure maximum uptime and zero headaches.

✅ Over 15 years’ experience

✅ Workshops in Perth and Brisbane

✅ Full parts, repairs, and rebuild services

✅ On-site consultation and troubleshooting

✅ Custom pump control and trailer builds

Get the Power of Air Working for You

If your site needs a safe, portable, and rugged water pumping solution—powered entirely by compressed air—MultiTorque has you covered.

📞 Call 1300 726 525

🌐 www.multitorque.com.au

🔗 Follow us on LinkedIn

📧 sales@multitorque.com

Call us now on 1300 726 525

Call us now on 1300 726 525

Email:

Email:

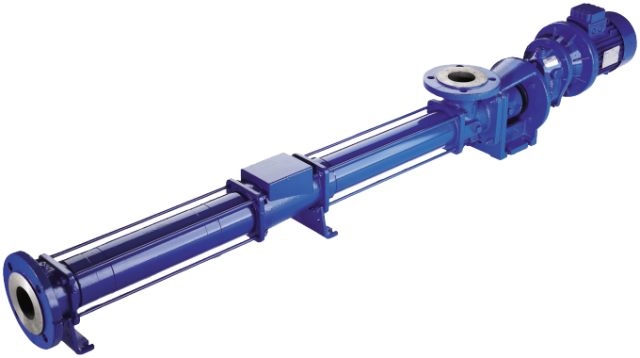

Heavy-Duty Design

Heavy-Duty Design Mining & Mineral Processing

Mining & Mineral Processing Wastewater Treatment

Wastewater Treatment Agriculture

Agriculture Chemical & Industrial

Chemical & Industrial Food & Beverage

Food & Beverage Pump repairs and full rebuilds

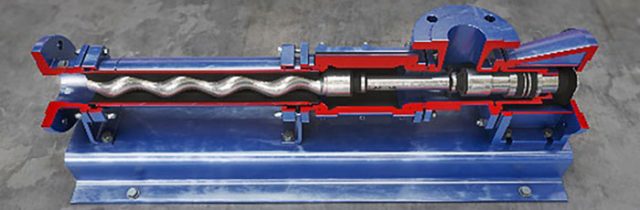

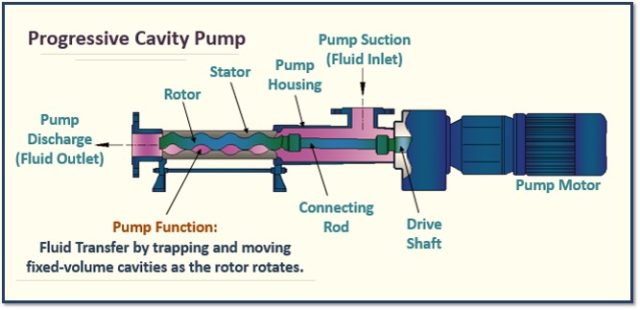

Pump repairs and full rebuilds Rotor and stator replacements

Rotor and stator replacements Drive shaft and mechanical seal servicing

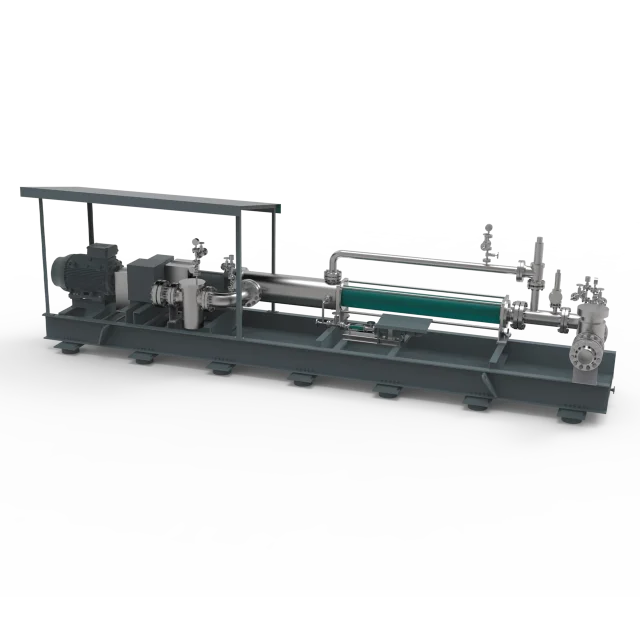

Drive shaft and mechanical seal servicing Custom trailer units with pump integration

Custom trailer units with pump integration In-house electrical panels tailored for Mono Pump systems

In-house electrical panels tailored for Mono Pump systems Deep technical knowledge of NOV Mono systems

Deep technical knowledge of NOV Mono systems Fully equipped workshop and mobile service vans

Fully equipped workshop and mobile service vans Licensed sparkies to wire up control systems

Licensed sparkies to wire up control systems Fast dispatch of Mono-compatible parts

Fast dispatch of Mono-compatible parts Custom-built mobile trailer units with Mono pumps onboard

Custom-built mobile trailer units with Mono pumps onboard