Selecting a reliable fire fighting system supplier is critical for businesses that prioritize safety, compliance, and protection of assets. MultiTorque Fire Suppression is a trusted partner for companies across Australia and New Zealand, providing certified, high-performance fire fighting systems tailored to industrial, transport, mining, marine, and manufacturing environments.

With over 15 years of experience, MultiTorque combines technical expertise with industry-approved solutions, ensuring every system meets regulatory requirements and delivers dependable performance when it matters most.

🔗 Visit our homepage: https://www.multitorque.com.au/

🔗 Connect with us on LinkedIn: https://www.linkedin.com/company/3176927

📞 Call MultiTorque: 1300 726 525

📧 Email: sales@multitorque.com

Why MultiTorque Stands Out as a Fire Fighting System Supplier

1. Certified Fire Fighting Systems

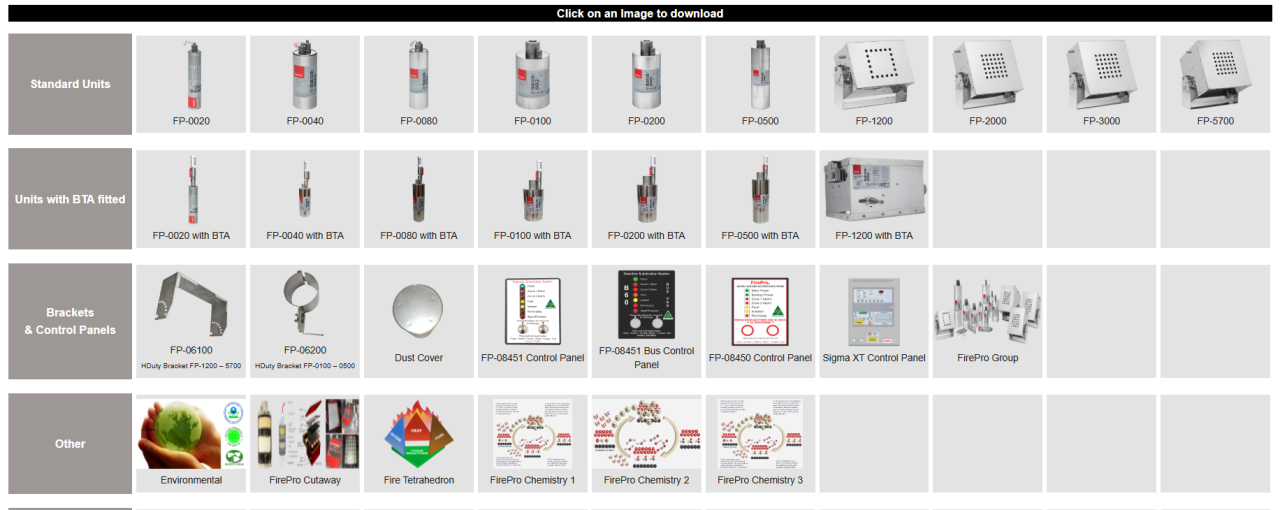

MultiTorque is an official distributor of FirePro condensed aerosol fire suppression systems. FirePro is certified to:

- AS 4487 Aerosol Systems

- AS 5062 Mobile Plant Fire Protection

These systems are pre-engineered to suppress Class A, B, C, and F fires, providing rapid, effective protection for mobile plant, machinery, vehicles, electrical cabinets, and confined spaces.

FirePro’s compact, low-maintenance design makes it ideal for high-risk industries, giving businesses a reliable solution without the complexities of traditional high-pressure systems.

Learn more about FirePro here: https://fsequip.au/

2. Wide Range of Fire Fighting Solutions

As a leading fire fighting system supplier, MultiTorque provides equipment and solutions for a variety of industries:

- Mining & Resources: Trucks, excavators, loaders, and other heavy machinery require fire suppression solutions that can operate in rugged environments.

- Transport & Logistics: Fleet vehicles, buses, and industrial trucks benefit from compact, automatic fire suppression systems that minimize downtime.

- Industrial Manufacturing: Production lines, warehouses, and workshops need fast-acting fire protection to reduce operational risk and equipment damage.

- Marine & Ports: Corrosion-resistant systems designed for vessels, port machinery, and dockside equipment ensure safety in challenging maritime conditions.

- Power Infrastructure & Electrical Cabinets: Protects sensitive electrical equipment and lithium battery installations from fire damage.

- Agriculture & Regional Machinery: Implements and vehicles operating in remote or high-risk areas need reliable suppression solutions.

By supplying systems for multiple sectors, MultiTorque ensures that businesses across Australia have access to fire fighting solutions that meet their unique operational needs.

3. National Presence for Fast Delivery and Support

With branches in Brisbane, Sydney, Perth, and New Zealand, MultiTorque guarantees fast delivery, reliable stock, and ongoing technical support. No matter the location, our team ensures that every fire fighting system is ready to install and fully operational, giving businesses peace of mind and continuity of operations.

4. Pre-Engineered Systems for Simplified Compliance

FirePro systems distributed by MultiTorque are designed to simplify compliance and reduce operational challenges:

- No high-pressure cylinders required

- Minimal maintenance and inspection needs

- Compact, space-saving modules suitable for confined spaces

- Environmentally friendly design with long service life

These features make FirePro systems the preferred choice for businesses that need fast, reliable fire suppression without complicated installation or ongoing maintenance issues.

5. Expertise Across Multiple Industries

With 15+ years of experience in fire suppression, MultiTorque provides tailored guidance for:

- Mining & resource operations

- Transport & logistics fleets

- Industrial manufacturing and workshops

- Marine and port facilities

- Civil construction machinery

- Agriculture and regional equipment

- Power infrastructure and electrical cabinets

Our technical knowledge ensures that all systems meet Australian safety standards, while also optimizing fire suppression for the unique needs of each sector.

6. Benefits of Partnering with MultiTorque

Choosing MultiTorque as your fire fighting system supplier provides multiple advantages:

- Certified, reliable systems designed for industrial and commercial use

- Technical guidance and expert support for installation and maintenance

- Rapid delivery and scalable solutions for multiple sites

- Reduced downtime and maintenance costs, improving operational efficiency

- Compliance with Australian Standards, ensuring legal and regulatory adherence

Our systems are designed to protect both people and assets, giving businesses confidence that they are prepared for emergencies.

Why Businesses Trust MultiTorque Fire Suppression

MultiTorque is committed to delivering high-performance fire fighting systems that combine safety, efficiency, and reliability. By partnering with us, businesses gain access to:

- Pre-engineered, low-maintenance systems

- Solutions tailored to specific industries

- National distribution and expert technical support

- Products that meet all Australian regulatory requirements

We focus on long-term client relationships, ensuring every system we supply continues to provide reliable protection for years to come.

Partner with MultiTorque Today

For businesses seeking a dependable fire fighting system supplier in Australia, MultiTorque offers certified systems, technical expertise, and nationwide support to protect your people, machinery, and assets.

🔗 Visit our homepage: https://www.multitorque.com.au/

🔗 Connect with us on LinkedIn: https://www.linkedin.com/company/3176927

📞 Call MultiTorque: 1300 726 525

📧 Email: sales@multitorque.com

MultiTorque Fire Suppression — delivering reliable, high-performance fire fighting systems across Australia and New Zealand.

Fire Fighting System Supplier Fire Fighting System Supplier Fire Fighting System Supplier Fire Fighting System Supplier