When it comes to vacuum pump systems in heavy-duty industrial applications, Nash pumps stand out for their durability and performance. Trusted in sectors like mining, power generation, chemical processing, and pulp and paper, these pumps are designed for reliability in tough environments. But like any mechanical equipment, they require proper maintenance, timely repairs, and access to quality parts to ensure optimal operation.

At MultiTorque, we specialise in the repair, servicing, and supply of Nash pumps across Australia. Whether you’re looking to extend the life of an aging unit or source a new or refurbished pump for your operation, we’ve got the expertise and the inventory to get the job done right.

What Is a Nash Pump?

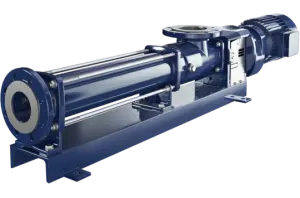

A Nash pump is a type of liquid ring vacuum pump, widely used in applications requiring a consistent vacuum level and robust performance. Originally developed by the Nash Engineering Company, these pumps are known for their simple design, ability to handle saturated gases, and low maintenance requirements.

Nash pumps work by creating a liquid seal within a rotating ring, which allows them to compress gases efficiently and reliably. This makes them ideal for:

- Vacuum filtration

- Flue gas desulfurization (FGD)

- Fly ash handling

- Evaporator systems

- Condenser exhausting

Why Choose Nash Pumps?

Nash pumps are built to withstand high workloads, rough conditions, and the demands of continuous operation. Their advantages include:

- Low maintenance requirements

- Non-pulsating vacuum output

- Corrosion-resistant materials

- Long operational lifespan

However, even the most reliable machines need attention from time to time, and that’s where MultiTorque comes in.

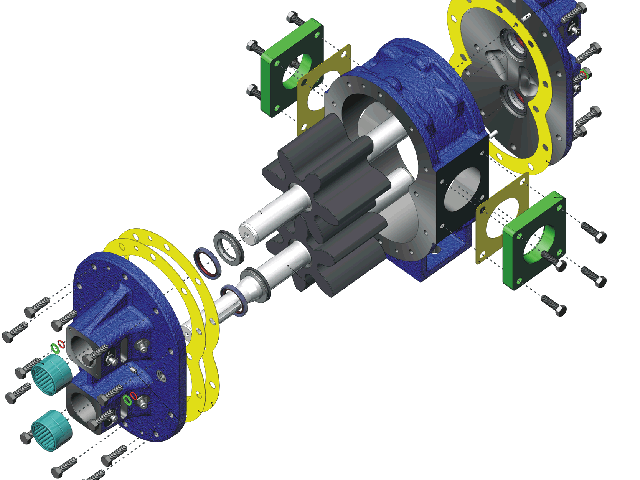

Expert Nash Pump Repairs

At MultiTorque, we provide comprehensive repair services for all models of Nash pumps. Whether it’s an older CL series or a newer 2BE series, our team is trained in identifying issues quickly and executing cost-effective repairs.

Common issues we handle include:

- Worn impellers or cones

- Seal and bearing failures

- Shaft misalignment

- Cavitation damage

- Corrosion from harsh chemicals

We begin with a full strip and assessment, including non-destructive testing (NDT) and precision measuring. We then provide a detailed repair report, options for refurbishment, and a clear quote before proceeding.

Our repairs include:

- Genuine or high-quality aftermarket replacement parts

- Precision balancing and machining

- Upgraded materials for longer service life

- Performance testing before delivery

Full Supply of Nash Pumps and Spare Parts

In addition to repair services, MultiTorque is a trusted supplier of new and refurbished Nash pumps. We offer:

- New Nash liquid ring vacuum pumps

- Refurbished and tested second-hand units

- Complete pump and motor assemblies

- Baseplates and couplings

- OEM and aftermarket spare parts

We work closely with clients to ensure correct sizing, compatibility with existing systems, and fast delivery to minimise downtime. Need a hard-to-find part? Our network of suppliers allows us to source components quickly—even for legacy models no longer in production.

Customised Solutions for Demanding Industries

MultiTorque services a broad range of industries that rely on Nash pumps. Our experience spans:

- Mining and minerals processing

- Oil and gas

- Water and wastewater

- Power stations

- Food and beverage

- Pulp and paper manufacturing

In these environments, uptime is critical. That’s why our team is available for rapid response, including on-site evaluations, emergency repairs, and express part delivery.

We also offer preventative maintenance programs designed to reduce unplanned breakdowns and extend pump life. By identifying early wear or performance drops, we help clients plan repairs before problems become costly.

Why Work with MultiTorque?

MultiTorque isn’t just a supplier—we’re your long-term partner in pump reliability. Here’s what sets us apart:

✅ Over 15 years of industry experience

We’ve built a solid reputation across Perth, Brisbane, and regional Australia for quality workmanship and dependable service.

✅ In-house repair workshops

Our purpose-built facilities are fully equipped to handle overhauls of all pump sizes, including high-capacity Nash units.

✅ Genuine care and custom support

We don’t take a one-size-fits-all approach. We understand every site has unique requirements, and we tailor our service accordingly.

✅ Fast turnaround and Australia-wide delivery

Whether you’re in a major city or a remote outback mine, we ship fast and get your equipment where it needs to be—on time, every time.

✅ Safety and compliance

All work is carried out to ISO and Australian standards. We take safety seriously, for both our team and yours.

Let’s Get Your Nash Pump Back to Work

If you’re experiencing reduced performance, strange noises, vacuum loss, or higher energy usage—don’t wait for a total failure. MultiTorque can assess your Nash pump quickly, offer honest advice, and deliver high-quality repairs or replacements to get your operations back on track.

Whether you’re chasing a full pump overhaul, need to buy a spare part, or want to upgrade an aging system, we’ve got you covered. Our team is ready to assist with fast, professional service.

Contact Us Today

📞 Phone: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: www.multitorque.com.au

Experience the MultiTorque difference—where reliability meets performance.