Efficient wastewater management is critical for both residential and industrial applications, and a Grundfos sewage pump delivers the reliability and performance required to handle complex sewage and wastewater systems. Trusted across Australia, Grundfos pumps are engineered to ensure smooth operation, minimise downtime, and provide long-lasting performance.

contact MultiTorque today at 1300 726 525 or email sales@multitorque.com. Our experts provide tailored solutions to ensure your pump system operates at peak efficiency.Why Choose a Grundfos Sewage Pump?

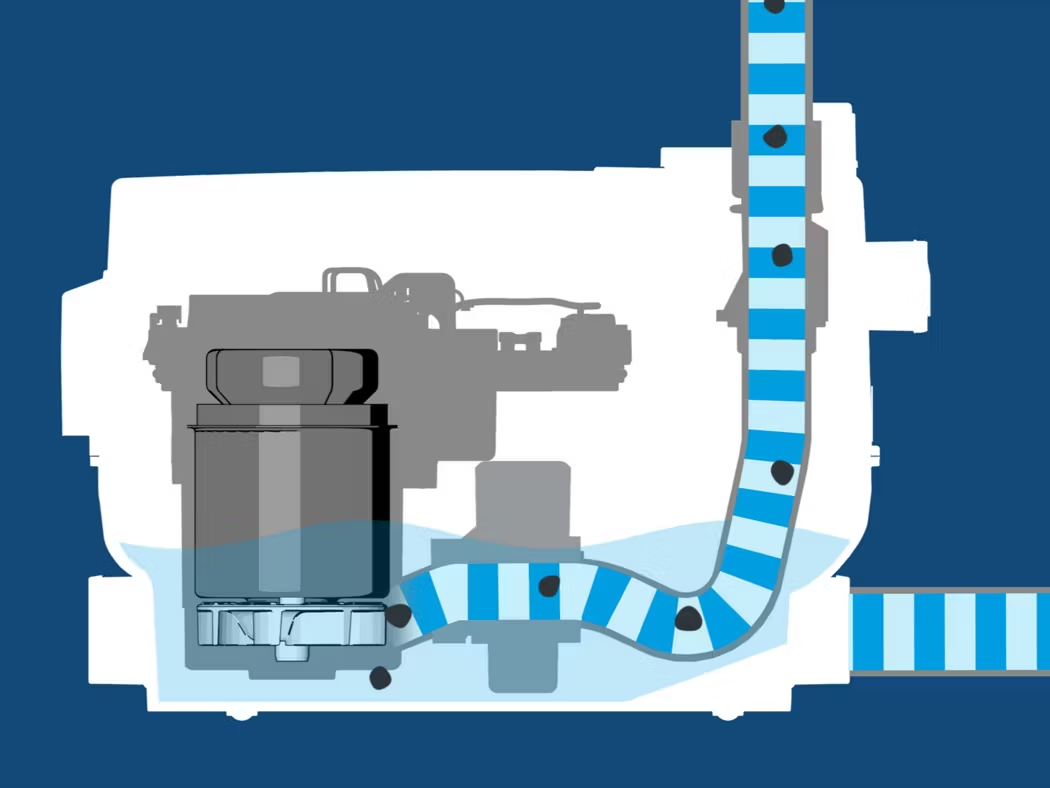

The Grundfos sewage pump is specifically designed to handle domestic, commercial, and industrial wastewater. Unlike standard pumps, sewage pumps can manage solid particles and fibrous materials without clogging, making them ideal for applications such as wastewater treatment plants, commercial facilities, and residential systems. With robust construction and high-quality components, these pumps are built to withstand the toughest environments.

Applications Across Residential and Industrial Sites

For homeowners, Grundfos sewage pumps are essential for basements, low-level bathrooms, kitchens, or laundry areas where gravity-based drainage isn’t possible. They can pump wastewater uphill or across long distances, preventing backflow and ensuring safe disposal.

In industrial and commercial settings, these pumps handle higher volumes of wastewater, sewage, and effluent. Industries such as manufacturing, mining, and hospitality benefit from Grundfos’s innovative designs, which provide reliable operation even under heavy duty, continuous use conditions. For tailored industrial pumping solutions, MultiTorque offers expert guidance, ensuring each pump is installed to meet site-specific needs.

Features and Benefits

The Grundfos sewage pump boasts numerous features that enhance reliability and efficiency:

- Clog-resistant design: Capable of handling solids up to a specific size, reducing blockages.

- Energy efficiency: Optimised motors lower energy consumption while maintaining flow performance.

- Durability: High-quality materials withstand harsh conditions and corrosive wastewater.

- Easy maintenance: Modular construction simplifies inspection, service, and replacement of components.

These benefits make Grundfos sewage pumps a long-term investment for homeowners, businesses, and industrial operators alike.

Installation and Support

Proper installation is crucial for maximising the lifespan and efficiency of a Grundfos sewage pump. MultiTorque offers professional installation services to ensure pumps operate at optimal performance. Our team also provides detailed system design advice, helping clients integrate sewage pumps into existing plumbing or industrial systems seamlessly. For ongoing support and servicing, MultiTorque’s LinkedIn page shares updates, projects, and technical insights from our team.

Sewage Pump Options from Grundfos

Grundfos offers a wide range of sewage pumps to suit varying needs. From small domestic units to large industrial pumps, there is a solution for every application:

- Submersible sewage pumps: Ideal for pits and tanks, these pumps operate underwater and deliver high efficiency with minimal noise.

- Dry-installed sewage pumps: Suitable for industrial or commercial setups where easy access for maintenance is required.

- Sewage grinder pumps: Capable of handling fibrous and solid waste, making them suitable for high-density residential or commercial sites.

MultiTorque can assist in selecting the right pump model, ensuring compatibility and optimal system performance.

Enhancing System Efficiency

Integrating a Grundfos sewage pump with control systems, valves, and backup units improves overall wastewater management. Advanced systems allow automatic operation, monitoring, and protection against overload or dry-running, which prolongs pump life and reduces downtime. MultiTorque provides full in-house servicing and expert recommendations to enhance efficiency and reliability of pump systems.

Australian Conditions and Compliance

Australian wastewater management regulations require pumps to comply with strict safety and environmental standards. Grundfos sewage pumps are engineered to meet these regulations, ensuring safe disposal and operational compliance. MultiTorque ensures that installations follow local codes, providing peace of mind to residential and commercial clients.

Maintenance and Longevity

Regular maintenance of a Grundfos sewage pump is essential to prevent wear and prolong operational life. MultiTorque offers maintenance services that include inspection, cleaning, and replacement of worn parts. Keeping your sewage pump in top condition reduces the risk of costly failures and environmental hazards. Explore MultiTorque’s pump services here.

Trusted Supplier and Technical Expertise

As a leading supplier of Grundfos pumps in Australia, MultiTorque combines product availability with technical expertise. Our team assists clients in choosing the right sewage pump, performing installations, and providing ongoing service support. With over 15 years of experience, we ensure reliable solutions for residential, commercial, and industrial applications.

Contact MultiTorque for Your Sewage Pump Needs

For Australian homes, businesses, and industrial sites, the Grundfos sewage pump provides a reliable and efficient solution to wastewater challenges. To discuss your project, installation, or maintenance requirements, contact MultiTorque today at 1300 726 525 or email sales@multitorque.com. Our experts provide tailored solutions to ensure your pump system operates at peak efficiency.