When it comes to high-pressure water systems, nothing beats the durability, performance, and precision of a Cat triplex pump. Engineered to withstand demanding applications and continuous operation, these pumps are trusted across industries including mining, industrial cleaning, oil & gas, and manufacturing.

At MultiTorque, we supply, source, and service Cat triplex pumps and components for clients all over Australia. Whether you’re looking for a new unit, replacement parts, or expert advice on pump selection, we’ve got the experience and support to help you get the job done right.

What Is a Cat Triplex Pump?

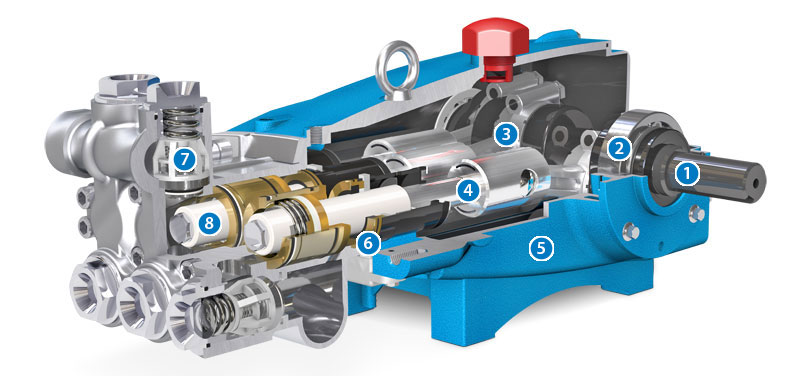

A Cat triplex pump is a high-pressure, positive displacement pump manufactured by Cat Pumps—one of the most trusted names in the industry. The term “triplex” refers to the pump’s design, featuring three plungers or pistons that work in sequence to create a steady, non-pulsating flow of fluid. This setup provides:

- Consistent flow and pressure

- Long service life

- Smooth operation with minimal vibration

- High efficiency across a wide range of applications

Cat triplex pumps are renowned for their quality machining, precise tolerances, and rugged construction, making them ideal for both continuous-duty and intermittent operations.

How Triplex Pumps Work

Triplex pumps operate by using a crankshaft to drive three pistons or plungers. Each piston creates suction on the intake stroke and then pressurises the fluid on the discharge stroke. With the three pistons working in offset cycles, the result is a continuous flow of fluid with fewer pressure spikes.

The design offers several key benefits:

- Lower pulsation than duplex or single-piston pumps

- Greater efficiency at high pressures

- Less stress on downstream components due to smoother flow

- Compact and space-efficient layout

Common Applications of Cat Triplex Pumps

The Cat triplex pump is known for its versatility. It can be configured for various applications, including:

- High-pressure washdowns (industrial and mining sites)

- Hydrostatic testing

- Water jet cutting

- Reverse osmosis systems

- Oil and gas well servicing

- Dust suppression systems

- Chemical injection

- Tank and pipe cleaning

- Firefighting systems

Because of their durability and resistance to corrosion, Cat triplex pumps are often found in demanding environments where downtime isn’t an option.

Why Choose Cat Triplex Pumps?

Cat Pumps has set the benchmark for industrial-grade triplex pumps. Here’s why many companies trust Cat triplex pumps over competitors:

✅ Superior Build Quality

Cat pumps are precision-machined and made from high-grade materials like stainless steel, nickel aluminum bronze, and ceramics, providing longer service life and corrosion resistance.

✅ Smooth, Pulsation-Free Flow

The triplex configuration reduces vibration and pulsation—ideal for systems that require stability and consistent pressure output.

✅ Long Maintenance Intervals

Cat triplex pumps are engineered for long run times between servicing. Properly maintained, they offer thousands of hours of reliable operation.

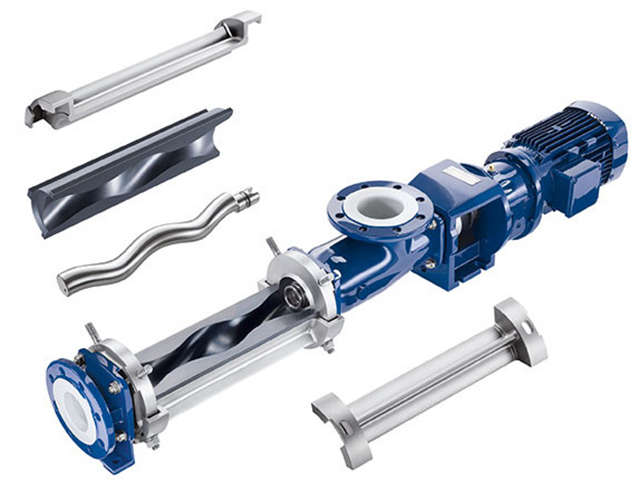

✅ Easy to Service

Standardised designs, simple disassembly, and widely available parts make Cat pumps extremely serviceable. This keeps maintenance costs low and turnaround fast.

Cat Triplex Pump Models

At MultiTorque, we work with a variety of Cat pump models to suit your system requirements:

- 3CP Series: Compact, durable pumps for moderate pressure applications

- 5CP Series: Heavy-duty pumps with higher flow capabilities

- 15 Frame and 35 Frame Models: Designed for continuous-duty high-pressure tasks

- High-Temperature Options: Suitable for fluid temperatures up to 190°C

- Custom Skid-Mounted Systems: Fully integrated units built to spec

Our team can help you select the right frame size, pressure rating, flow capacity, and material configuration for your application.

Service and Support from MultiTorque

MultiTorque doesn’t just supply Cat triplex pumps—we back them with workshop-based support, fast turnaround, and expert advice. Our team is experienced in servicing high-pressure pump systems and can handle:

- Seal and valve replacement

- Ceramic plunger inspections

- Pump alignment and testing

- Full pump rebuilds and reassembly

- Diagnostics and troubleshooting for performance issues

We also carry genuine and aftermarket parts to reduce lead times and keep your system running without delay.

Custom Pump Systems and Trailers

Looking to build a mobile high-pressure system? At MultiTorque, we also design custom trailer-mounted pump units, including Cat triplex pump systems for:

- Mine site washdowns

- Dust suppression

- Pipeline cleaning

- Remote site maintenance

- Tank cleaning and pressure testing

Our trailers are designed for off-road durability, easy access, and efficient hydraulic or electric integration. We can spec out the entire system—engine, pump, controls, hosing, and fittings.

Why Choose MultiTorque?

We’ve built our reputation on reliability, fast service, and solutions that last. Here’s what makes us your go-to supplier for Cat triplex pumps in Australia:

- ✅ Over 15 years of experience

- ✅ Workshops in Perth and Brisbane

- ✅ Custom fabrication and trailer builds

- ✅ Local stock and fast sourcing

- ✅ Genuine and aftermarket Cat pump parts

- ✅ Honest advice with no fluff

We support mining, industrial, agriculture, and infrastructure clients who depend on high-performance pump systems—day in, day out.

Contact MultiTorque Today

Ready to upgrade your pump system with a Cat triplex pump? Need a mobile unit or just some expert guidance?

📞 Call us now on 1300 726 525

📧 Email: sales@multitorque.com

🔗 Visit our website: https://www.multitorque.com.au

🔗 Connect with us on LinkedIn: MultiTorque Industries

Whether you’re after a new pump, a replacement part, or a full custom build, we’re here to deliver.