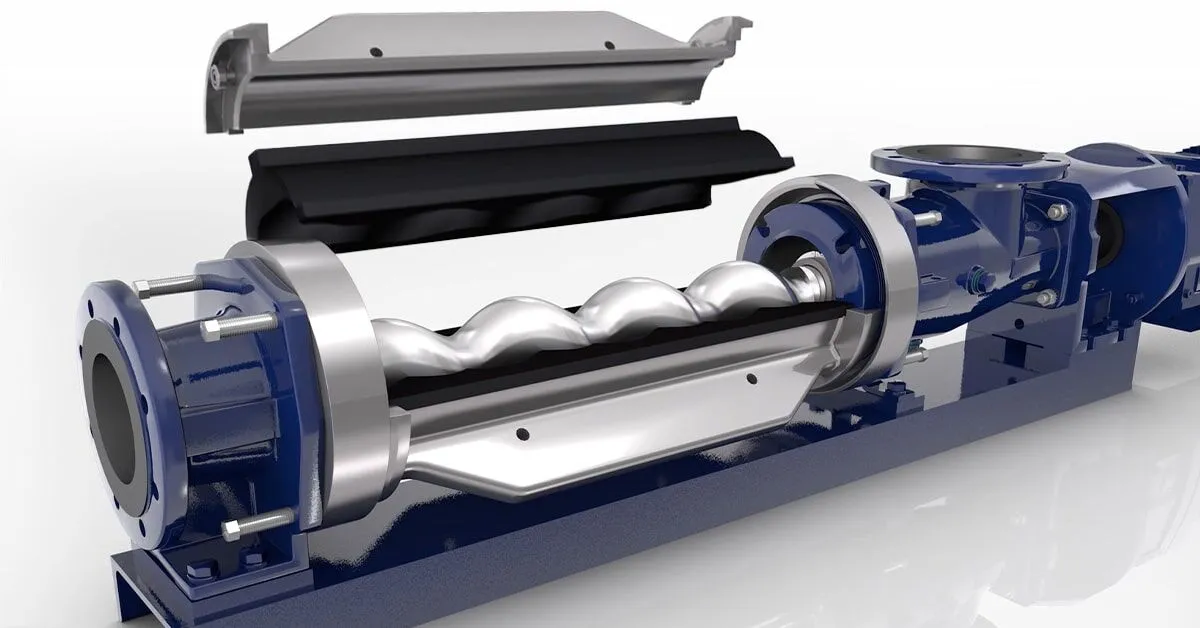

When it comes to reliable progressive cavity pumps, Seepex stands out as one of the world’s most trusted manufacturers. Known for their innovation, quality engineering, and longevity, Seepex pumps are used across industries such as wastewater, food processing, mining, oil & gas, and chemical processing. However, to ensure you’re getting authentic, expertly supported products, sourcing from authorised Seepex distributors is essential.

At MultiTorque, we proudly supply parts and service support for Seepex pumps, assisting customers across Australia with sourcing genuine components and providing expert guidance tailored to your operation’s needs. Whether you’re after a replacement rotor, stator, or a complete pump unit, working with trusted Seepex distributors ensures long-term performance and peace of mind.

Why Choose Seepex Pumps?

Before diving into the role of Seepex distributors, it’s worth exploring what makes Seepex pumps such a popular choice across industries:

- Progressive Cavity Technology: Seepex specialises in progressive cavity (PC) pump design, which excels in handling viscous, shear-sensitive, or abrasive materials. This makes them ideal for sludge, slurries, chemicals, and more.

- Modular Design: Most Seepex pumps are built using a modular system. This makes servicing, customisation, and part replacement easier and more cost-effective.

- Durability and Efficiency: These pumps are built to last in the harshest conditions, offering minimal pulsation and high volumetric consistency, which reduces downtime and energy consumption.

- Custom Applications: From dosing and metering to open hopper and macerator systems, Seepex provides solutions tailored to specific industrial challenges.

What Does a Seepex Distributor Do?

Seepex distributors serve as the critical link between the manufacturer and end users. Here’s what you can expect when working with a reliable Seepex distributor like MultiTorque:

1. Genuine Parts Supply

Using genuine Seepex parts ensures your equipment runs at peak performance. We supply authentic rotors, stators, seals, connecting rods, and other key components that match your pump model exactly.

2. Expert Support and Technical Advice

Seepex distributors understand the full technical scope of the products they represent. At MultiTorque, our specialists help you select the correct model or part, assess compatibility, and provide real-world recommendations for longevity and performance.

3. Warranty and Manufacturer Support

When you work through an authorised distributor, you benefit from Seepex’s official warranty and service protocols—something grey-market or non-authorised suppliers can’t provide.

4. Faster Turnaround and Logistics

As a professional supplier, MultiTorque works directly with Seepex’s supply chain to reduce delays. We also carry stock of high-demand Seepex parts for rapid dispatch Australia-wide.

5. Local Knowledge, National Reach

Operating in both Perth and Brisbane, MultiTorque serves customers across Australia. We understand the industries we serve—whether you’re in mining, wastewater, agriculture, or food—and can tailor pump solutions accordingly.

Why Source Through MultiTorque?

There are plenty of suppliers out there—but when choosing Seepex distributors, not all are created equal. Here’s why MultiTorque stands out:

- Over 15 Years of Industry Experience

We’ve been delivering pump solutions for over a decade, and our technical team has hands-on experience with Seepex systems in the field. - Custom Solutions

From engineered skid systems to trailer-mounted PC pump units, we can help design and build a system using Seepex components to meet your operational needs. - In-House Repairs and Testing

We don’t outsource repairs. All pump repairs are carried out in our fully equipped workshop. We test every unit before it goes out the door, ensuring top-tier quality control. - Customer-First Approach

We focus on long-term relationships, not short-term sales. Our clients return because they trust our support, our knowledge, and our ability to deliver—even under pressure.

Common Seepex Pump Series and Applications

MultiTorque supplies a wide range of Seepex pump models. Some of the most common series we work with include:

- BN Series: Versatile for various applications, including sludge transfer and viscous materials.

- MD Series: Ideal for precise metering and dosing applications.

- BTEX Series: Heavy-duty open hopper pumps designed for dewatered sludge and pasty media.

- CS Series: Hygienic pumps used in the food, beverage, and pharmaceutical industries.

Whether you’re sourcing replacement parts or looking to expand capacity with a new installation, MultiTorque is your go-to name among Australian Seepex distributors.

Industry Applications of Seepex Pumps

The versatility of Seepex progressive cavity pumps makes them suitable for:

- Wastewater Treatment: Sludge handling, chemical dosing, and thickened biosolids transfer.

- Food & Beverage: Gentle product handling for yogurt, sauces, and fruit pulp.

- Mining: Abrasive slurry pumping, dewatering, and tailings handling.

- Oil & Gas: High-pressure chemical injection, crude transfer, and produced water systems.

- Agriculture: Pumping manure, feed additives, or effluent.

Every industry has unique challenges—but Seepex’s modularity, combined with MultiTorque’s hands-on support, ensures we deliver reliable, long-lasting solutions.

Looking for Seepex Distributors in Australia?

Look no further. MultiTorque is your trusted source for Seepex distributors and pump solutions across Australia. Whether you’re after routine parts, urgent replacements, or a long-term procurement partner—we’ve got you covered.

You can explore more about our services and pump products at https://www.multitorque.com.au. For professional guidance, give us a call at 1300 726 525 or email sales@multitorque.com.

Let us help you keep your Seepex systems running smoothly with genuine parts, expert knowledge, and a no-nonsense approach to performance.

Also, stay updated with our latest news and installations by following us on LinkedIn: https://www.linkedin.com/company/multitorque-industries