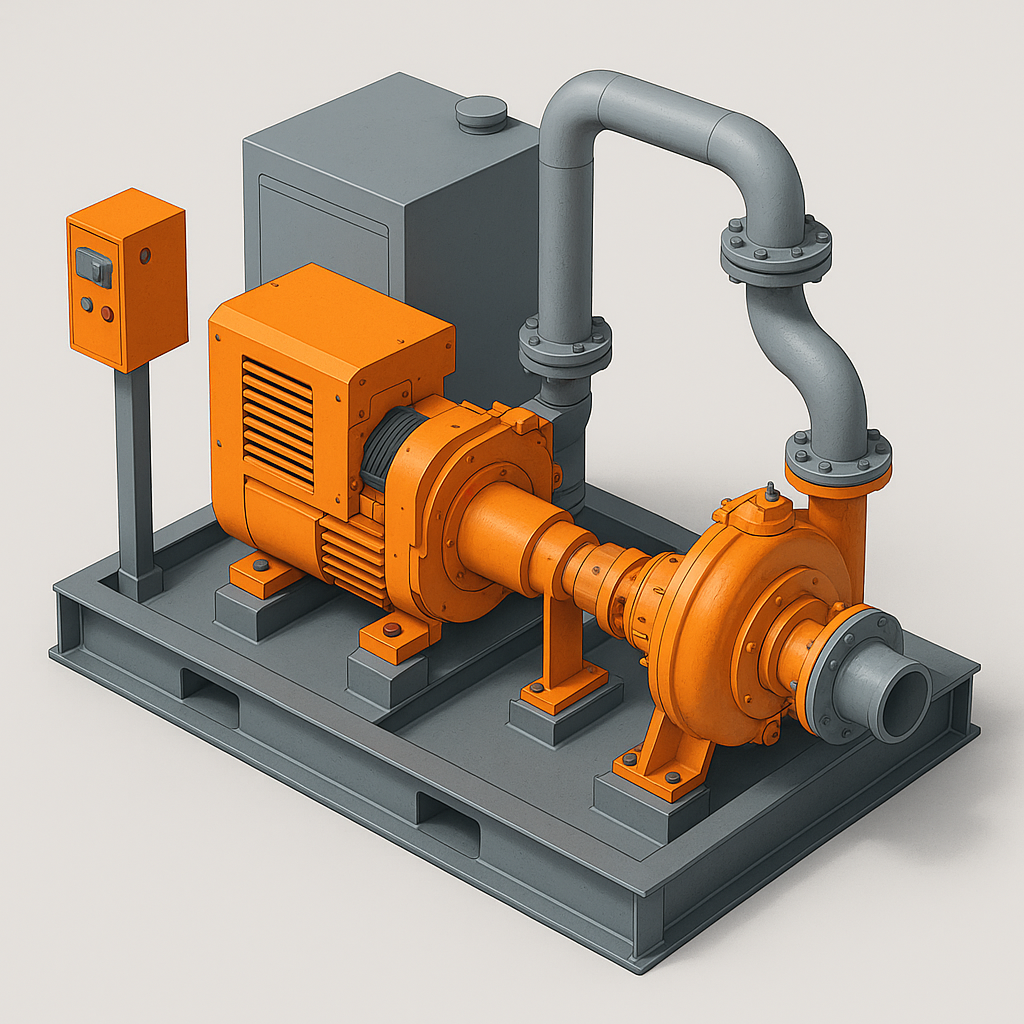

Mud pumps are vital in mining, oil & gas, and drilling operations. They deliver high-pressure slurry and fluids to support drilling and extraction processes. Access to reliable mud pump parts suppliers is essential to maintain efficiency, reduce downtime, and ensure operational safety. MultiTorque provides premium parts, technical expertise, and tailored solutions for all types of mud pumps across Australia.

With over 15 years of experience, MultiTorque has built a reputation as a trusted supplier of industrial and mining pump components, offering solutions that meet the demands of challenging and abrasive environments.

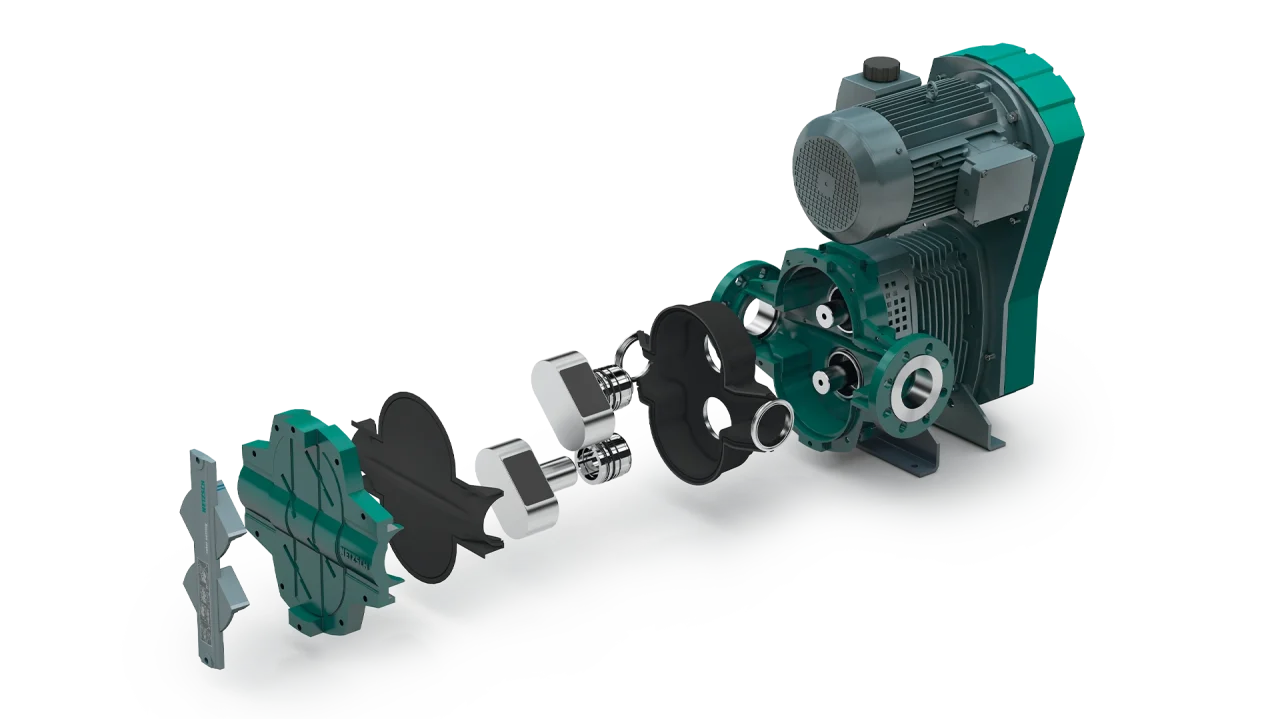

What Are Mud Pump Parts?

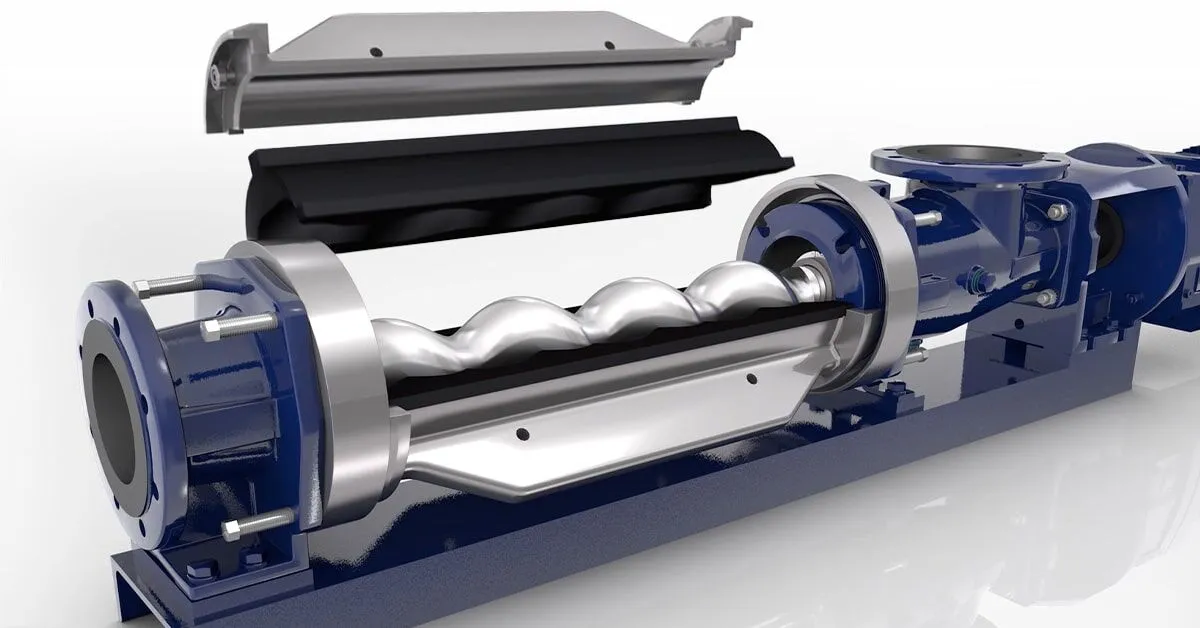

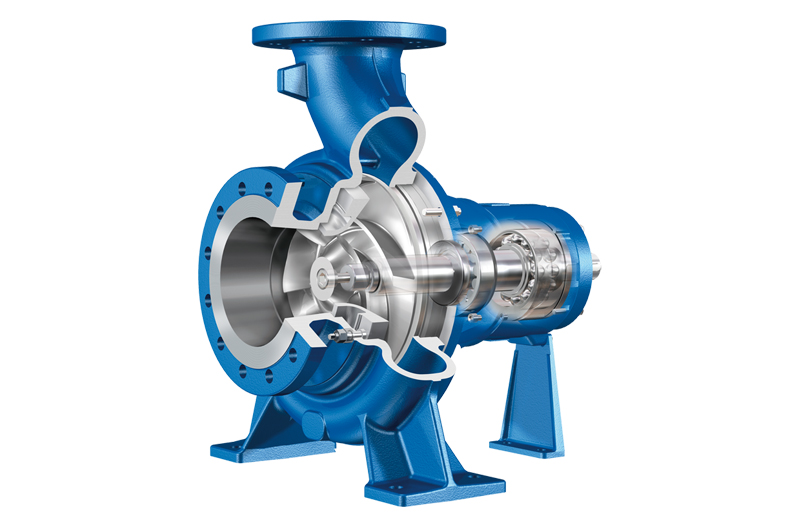

Mud pump parts are the individual components that ensure the reliable operation of mud pumps. These pumps handle abrasive slurries, high pressures, and continuous operation, making high-quality parts critical for performance and durability.

Common mud pump parts include:

- Pistons and Liners: Essential for high-pressure fluid transfer

- Valves and Seats: Ensuring efficient flow and preventing backflow

- Shafts and Bearings: Reducing friction and wear

- Gaskets and Seals: Preventing leaks and maintaining hydraulic integrity

- Fluid Ends and Manifolds: Distributing slurry accurately and efficiently

MultiTorque supplies genuine, durable parts designed to withstand the rigorous conditions of mining and drilling operations.

Industries That Depend on Mud Pump Parts

MultiTorque provides mud pump parts to several key industries:

- Mining & Mineral Processing: For high-pressure slurry transfer and dewatering (see centrifugal pump skid solutions)

- Oil & Gas Drilling: Components for drilling mud pumps and high-pressure fluid systems (read about oil and gas pump solutions)

- Construction & Civil Projects: Pumps for concrete slurry and water management

- Industrial Applications: Supporting high-volume fluid transfer and abrasive slurry handling

- Agricultural Projects: Handling irrigation and slurry pumping systems

Reliable mud pump parts are essential to prevent downtime and maintain safety in demanding environments.

Types of Mud Pump Parts Supplied

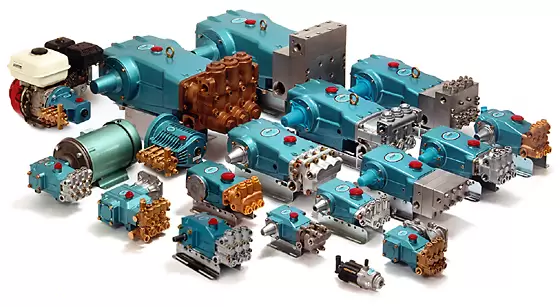

MultiTorque provides a comprehensive range of mud pump parts suitable for various applications:

- Fluid Ends: Pistons, liners, and manifolds for efficient slurry handling

- Valve Assemblies: High-quality valves and seats for precision control

- Shafts and Bearings: Long-lasting components for smooth operation

- Gaskets and Seals: Leak-proof solutions for high-pressure applications

- Custom Components: Parts tailored to specific pump models and operational requirements

Each part is designed to meet stringent quality standards, ensuring longevity and performance even under the harshest conditions.

Benefits of Choosing MultiTorque as Your Mud Pump Parts Supplier

Working with MultiTorque provides several advantages for mining, oil, and industrial operations:

- High-Quality Components: Genuine, durable parts designed to withstand abrasive fluids

- Expert Guidance: Assistance in selecting the correct parts for your specific pump model

- Custom Solutions: Tailored components for unique operational needs

- In-House Workshop: Efficient repairs and parts replacement without outsourcing (read more about industrial pump skid solutions)

- Nationwide Support: Perth and Brisbane branches ensuring fast delivery and service

- Extended Pump Life: High-quality parts reduce wear and maintenance costs

MultiTorque ensures that every component supplied contributes to reliable, safe, and efficient pump performance.

Maintenance Tips for Mud Pumps

To maximise the lifespan of your mud pumps, proper maintenance and high-quality parts are essential:

- Regularly inspect fluid ends, pistons, and liners for wear

- Replace worn valves, seats, and bearings promptly

- Maintain proper lubrication to reduce friction and wear

- Monitor pump pressure and flow rates to detect early signs of failure

- Schedule professional servicing with MultiTorque for preventative maintenance

These practices, combined with premium parts from MultiTorque, keep pumps operating efficiently and safely.

Why MultiTorque Stands Out

MultiTorque is a leading mud pump parts supplier in Australia because of:

- Experience: Over 15 years providing mining and industrial pump solutions

- Technical Expertise: Skilled in fluid ends, positive displacement pumps, and centrifugal pumps

- In-House Workshop Services: Efficient repairs and parts replacement without outsourcing (read about Mono pump solutions)

- Custom Solutions: Components designed for complex, high-pressure pumping operations

- Customer-Focused Service: Commitment to reliability, efficiency, and long-term partnerships (see bearing suppliers)

Companies that choose MultiTorque gain access to high-quality parts, professional support, and reliable pump performance.

Contact MultiTorque

For premium mud pump parts suppliers in Australia, contact MultiTorque today. Our team provides expert advice, genuine components, and support to ensure your pumps operate safely and efficiently.

📞 Phone: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: www.multitorque.com.au

🔗 LinkedIn: MultiTorque Industries

Trust MultiTorque for durable, high-quality mud pump parts that keep your mining and industrial operations running smoothly.