In every industrial, mining, commercial and high-risk environment, having reliable fire protection equipment is not optional—it is essential. The ability to respond instantly to an emerging fire can determine whether a business faces minimal downtime or a complete operational shutdown. At the centre of this readiness is the fire ext, a critical component of any site’s first-response fire safety strategy. MultiTorque, recognised across Australia for supplying dependable equipment to heavy industry, offers a complete range of extinguishers, suppression units and accessories designed for performance, compliance and long-term reliability.

For high-quality fire ext solutions designed for Australia’s toughest industries, MultiTorque is ready to support your fire protection requirements.

Head here to see our full range and product info: https://fsequip.au/

📞 1300 726 525

📧 sales@multitorque.com

A fire ext must be durable, correctly rated and suitable for specific hazards. Industrial sites do not operate under the same conditions as small offices or retail environments. They involve flammable liquids, high-powered electrical systems, machinery, hydraulic circuits, fuels, chemicals and heavy equipment. MultiTorque’s portfolio of fire protection equipment is engineered for these demanding applications, ensuring that every extinguisher or suppression unit is capable of rapid deployment when it matters most.

At MultiTorque, we work with businesses that require more than just a basic extinguisher. Our customers operate assets worth millions of dollars, from mobile plant to production systems. They rely on well-built fire ext products to control emergencies before they escalate. This is why MultiTorque focuses on high-quality extinguishers, industrial suppression systems and accessories that meet strict Australian Standards. Every product is selected for durability, safety and suitability for the Australian industrial landscape.

A key advantage of choosing MultiTorque is access to a wide range of fire ext models tailored to different categories of fires. Class A fires involving paper, plastics and wood require a specific type of extinguisher, while Class B fires involving flammable liquids require a different approach. Class E electrical fires demand extinguishers that will not conduct electricity or damage components. For industrial machinery, workshops, switch rooms, fuel bays and equipment housing, selecting the wrong fire ext can create additional hazards. MultiTorque helps clients choose the correct extinguishers to match their operational needs and compliance requirements.

Different environments demand different technologies. Dry chemical extinguishers are common across general industrial settings due to their versatility and rapid suppression capability. Carbon dioxide extinguishers, on the other hand, offer a residue-free solution ideal for electrical cabinets, control panels and sensitive equipment. Foam models, water extinguishers and specialist units each have their place depending on the hazard profile. MultiTorque ensures businesses receive correct guidance and product match for each application, improving both safety and operational resilience.

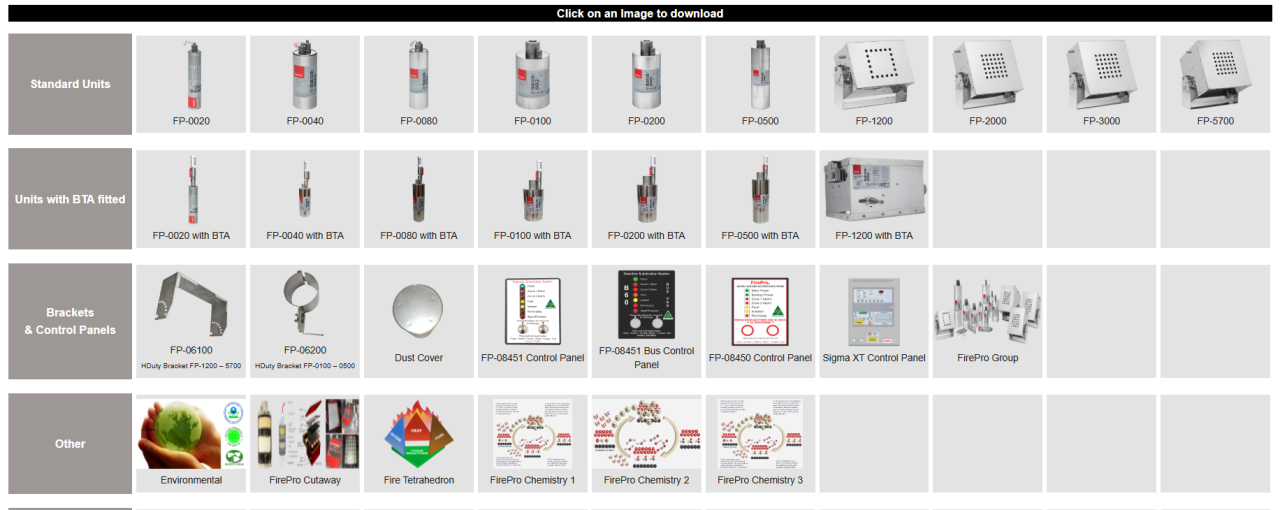

While the fire ext is essential as a first-line defence, many industries also require integrated suppression systems for enclosed equipment or high-risk machinery. Through MultiTorque Fire Suppression, we supply advanced aerosol suppression technology designed for mobile plant, vehicles, electrical enclosures and industrial assets. These systems activate thermally or electrically and require no high-pressure cylinders or complex pipework, making them ideal for industries seeking reliable protection with minimal maintenance requirements.

Industrial operators across Australia depend on MultiTorque for fire ext products because our solutions are built for harsh conditions. The mining, civil construction, transport, logistics, marine, agriculture and heavy manufacturing sectors rely on equipment that withstands dust, vibration, heat, moisture and demanding operational cycles. MultiTorque’s extinguishers and suppression systems are chosen for their robustness and proven reliability in real-world environments.

Supply capability is another reason MultiTorque is the preferred fire ext provider for many businesses. With distribution across Perth, Brisbane and national delivery, companies benefit from fast dispatch, consistent stock availability and access to technical support when needed. Whether outfitting a single workshop or equipping an entire fleet of mobile plant, MultiTorque provides scalable solutions designed around long-term business relationships and ongoing operational needs.

Modern compliance frameworks require that businesses not only install the correct fire ext equipment but also ensure that products meet Australian Standards and remain in suitable working condition. MultiTorque supports customers by supplying compliant equipment that aligns with industry regulations and operational guidelines. Proper selection and placement of extinguishers reduce risk, support insurance requirements and strengthen overall workplace safety.

A fully equipped worksite must incorporate the correct types, quantities and classifications of fire ext units. Common locations include workshop bays, fuel and chemical storage areas, machinery stations, generator rooms, electrical switchboards, control rooms, manufacturing zones, vehicle service areas, equipment storage facilities and operational plant areas. MultiTorque assists with product choice to ensure your fire protection layout aligns with risk exposure and industry best practices.

In addition to extinguishers and suppression systems, MultiTorque supplies brackets, signage, mounting equipment, accessories and additional fire protection hardware. Businesses requiring a comprehensive safety setup can rely on us as a single supplier, reducing complications and ensuring product compatibility across their site. For more information on our industrial equipment supply capabilities, visit our main website: https://www.multitorque.com.au/

With more than 15 years supporting Australian industry, MultiTorque has built a reputation for reliability, durability and customer-focused service. Our commitment to quality ensures that every fire ext product we supply meets the expectations of operators who cannot afford equipment failure during an emergency. We work closely with clients to understand their needs and provide solutions that enhance operational safety and protect valuable assets.

To stay updated with MultiTorque’s latest products and industry insights, follow us on LinkedIn: https://www.linkedin.com/company/3176927

For high-quality fire ext solutions designed for Australia’s toughest industries, MultiTorque is ready to support your fire protection requirements.

📞 1300 726 525

📧 sales@multitorque.com