When it comes to precision, efficiency, and durability in fluid handling, progressive pumps are leading the charge across a wide range of industries. Also known as progressive cavity pumps, these positive displacement pumps are specifically designed for consistent flow rates, even in the most demanding applications. Whether you’re in wastewater treatment, oil & gas, mining, or food processing, understanding how these pumps operate—and why they outperform traditional designs—can make a significant impact on your system’s performance.

What Are Progressive Pumps?

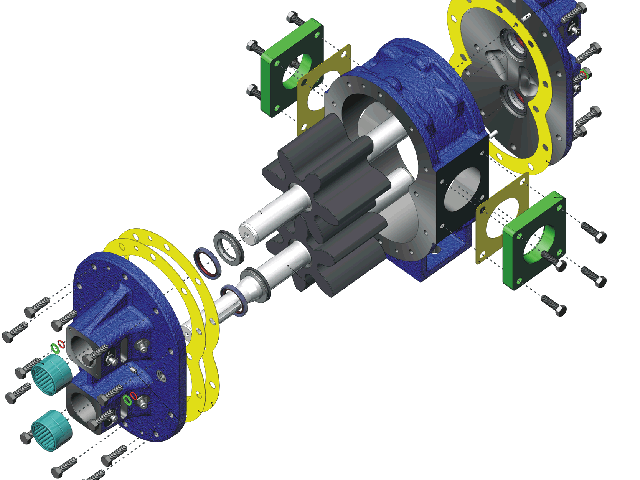

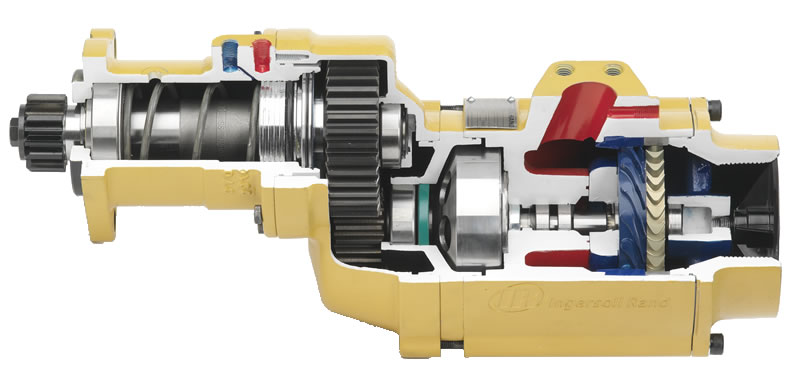

Progressive pumps are a type of positive displacement pump that uses a helical rotor and stator mechanism to move fluid through cavities formed within the pump housing. As the rotor turns, fluid is transported through a sequence of progressing chambers, delivering smooth, low-shear, and pulsation-free flow. This makes progressive pumps ideal for handling shear-sensitive or viscous materials such as sludge, slurry, oils, and even delicate food products.

Unlike centrifugal pumps, which rely on impeller speed and pressure, progressive pumps excel at moving viscous or abrasive fluids with consistent flow—regardless of pressure changes or system resistance.

Key Benefits of Progressive Pumps

Progressive pumps offer a host of advantages that make them the go-to solution for industrial clients:

- Consistent Flow: With minimal pulsation and turbulence, progressive pumps ensure uniform delivery of product.

- Self-Priming: These pumps can draw fluid without external priming, saving time and effort during installation.

- Low Shear Pumping: Ideal for shear-sensitive fluids, preserving product integrity in food or chemical applications.

- Handles Viscous and Abrasive Materials: Suitable for thick sludge, slurry, and fluids containing solids.

- High Suction Lift Capability: Progressive pumps can handle applications with difficult suction conditions.

Applications Across Industries

At MultiTorque, we supply, service, and repair progressive pumps used in a broad range of Australian industries. Some key applications include:

- Wastewater Treatment: For transferring thick sludge and sewage with minimal clogging.

- Mining Operations: Moving abrasive slurry or tailings from one process to the next.

- Oil & Gas: Transferring viscous oils, drilling mud, and other hydrocarbon-based fluids.

- Food & Beverage: Handling molasses, fruit purees, and other sensitive or viscous consumables.

- Agriculture: Pumping manure, fertilisers, or thick agricultural waste.

These pumps offer industry-grade reliability, low maintenance, and long service life when properly maintained—making them ideal for long-term cost savings.

Progressive Pump Maintenance and Repairs

Like any mechanical system, progressive pumps require periodic maintenance to ensure optimal performance. This includes:

- Checking and replacing worn stators or rotors

- Inspecting seals and gaskets

- Monitoring motor and coupling alignment

- Lubricating components as needed

MultiTorque offers full progressive pump repair and servicing capabilities across both our Perth and Brisbane branches. We carry genuine parts and offer emergency support when unplanned downtime hits.

Why Choose MultiTorque?

With over 15 years of experience in industrial pumping systems, MultiTorque is a trusted name in progressive cavity pump supply, servicing, and support. Our team works with top brands like NOV, Orbit, and Napco, offering tailored solutions that match your system requirements. We also manufacture custom pump trailers and skid units for remote or mobile operations.

Whether you’re upgrading your current system, looking for a more reliable pump option, or needing urgent repair, we’ve got your back—with fast response times, genuine parts, and real industry expertise.

Get in Touch with MultiTorque

If you’re searching for high-performance progressive pumps for industrial use, don’t leave it to chance. Contact MultiTorque today and speak with a pumping expert who understands your industry.

📞 Call us on 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: www.multitorque.com.au

🔗 LinkedIn: MultiTorque on LinkedIn