The mining industry demands robust, reliable, and high-performance pumping solutions to ensure smooth operations. As a top mining pump supplier, MultiTorque provides premium pumps, expert advice, and customised solutions tailored to the unique requirements of mining applications.

With over 15 years of experience, MultiTorque has become a trusted Australian supplier of pumps for mining, industrial, and agricultural sectors. Our solutions focus on durability, efficiency, and long-term reliability.

📞 Phone: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: www.multitorque.com.au

🔗 LinkedIn: MultiTorque Industries

What Are Mining Pumps?

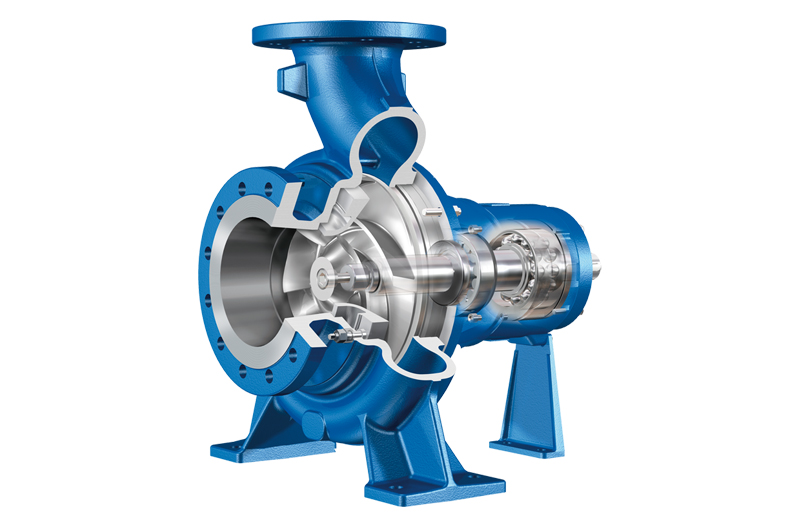

Mining pumps are specialised industrial pumps designed to handle the demanding conditions of mining operations. These pumps transfer water, slurry, chemicals, and other fluids efficiently, even under high pressure or abrasive conditions.

Key features include:

- Durable Construction: Designed to withstand harsh mining environments

- High Performance: Consistent flow and pressure for critical operations

- Versatility: Suitable for water, slurry, and chemical applications

- Energy Efficiency: Minimising operational costs

- Ease of Maintenance: Simplified access for repairs and servicing

Choosing the right mining pump supplier ensures your operations maintain peak efficiency and reduce downtime.

Industries Relying on Mining Pumps

MultiTorque supplies mining pumps across multiple sectors:

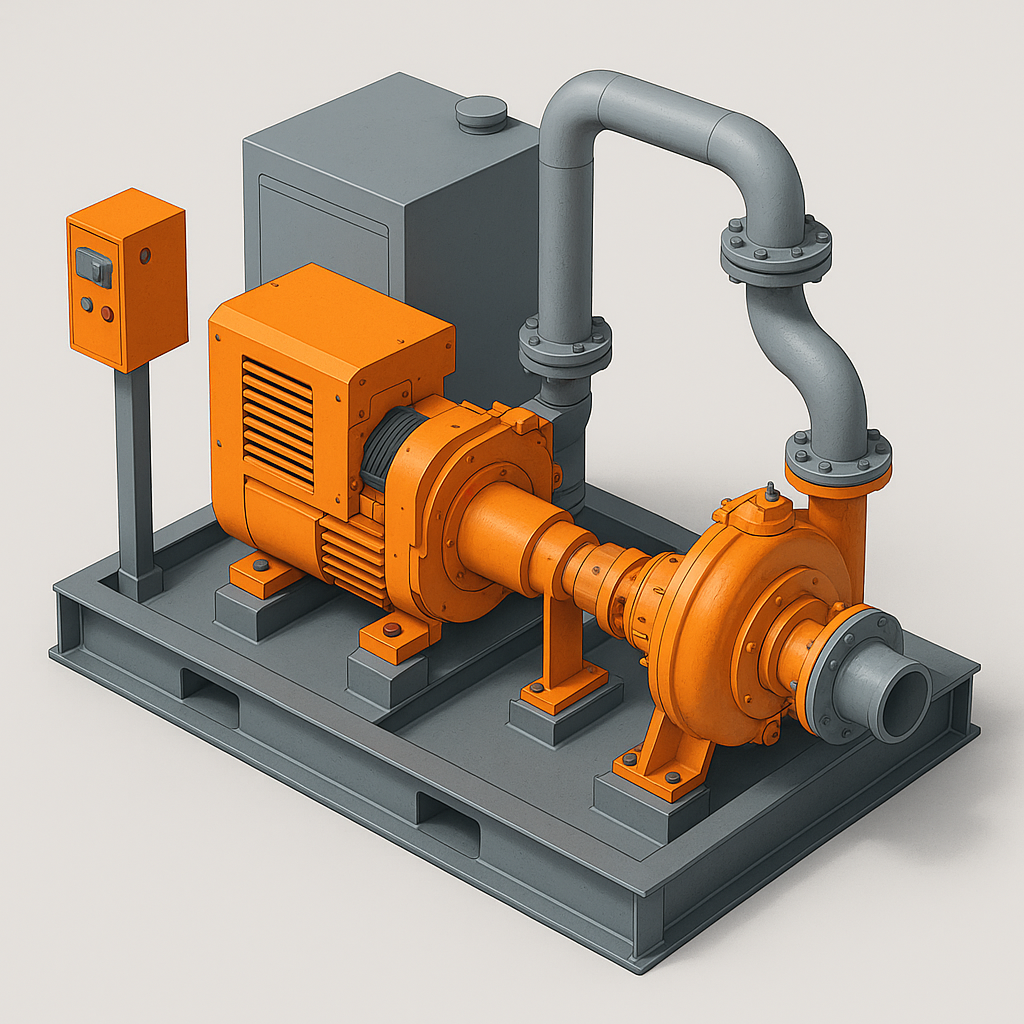

- Mineral Processing Plants: Pumps for slurry, dewatering, and water transfer (see centrifugal pump skid solutions)

- Chemical Handling in Mining: Safe and efficient chemical pump systems (read about chemical pump skid systems)

- Oil & Gas Mining Operations: High-pressure pumping solutions (read about oil and gas pump solutions)

- Water Management: Reliable pumps for irrigation and site dewatering

- Industrial Processing: Supporting large-scale mining operations with durable pump solutions

Reliable mining pump suppliers like MultiTorque provide both products and expertise to keep operations running efficiently.

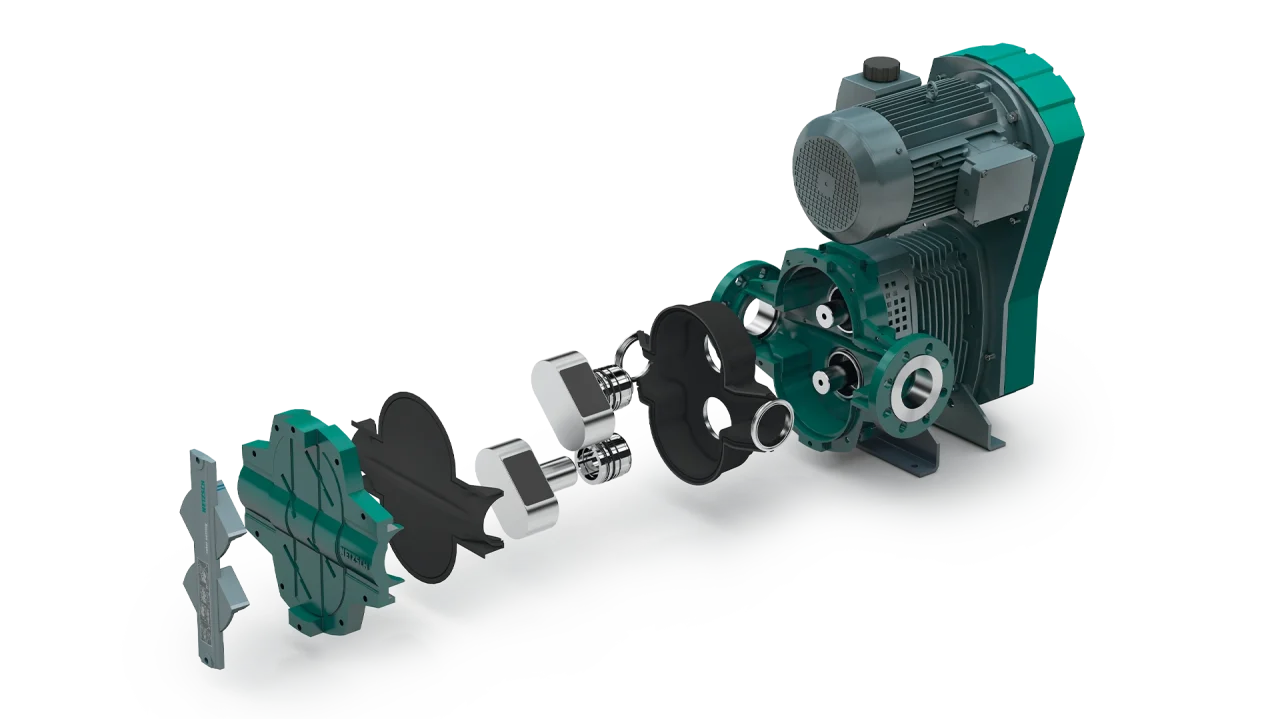

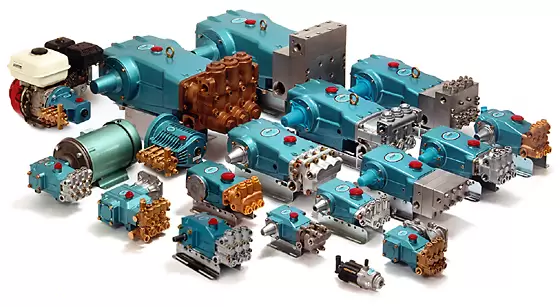

Types of Mining Pumps Supplied

MultiTorque offers a wide range of mining pumps suitable for different applications:

- Centrifugal Pumps: Ideal for high-volume water and slurry transfer (read about NOV Mono pump systems)

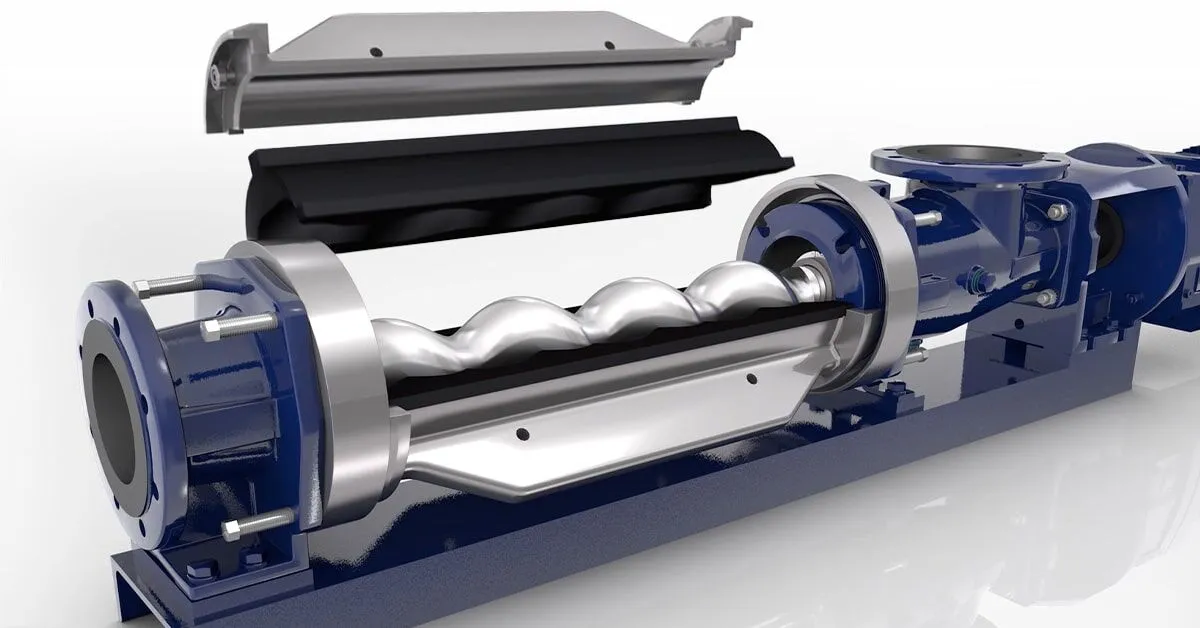

- Positive Displacement Pumps: For precise dosing and consistent high-pressure applications (read about Mono pump solutions)

- Submersible Pumps: Designed for dewatering and flood control

- Skid-Mounted Pump Systems: Pre-assembled solutions ready for deployment

- Custom Pump Solutions: Tailored designs for unique mining requirements

Each pump is selected to suit the specific fluid type, flow rate, and pressure requirements of the mining operation.

Benefits of Partnering with MultiTorque

Choosing MultiTorque as your mining pump supplier provides several advantages:

- Expert Consultation: Guidance on pump selection based on mining requirements

- Premium Brands: High-quality pumps designed for harsh conditions

- Custom Solutions: Tailored skid-mounted and integrated pump systems

- In-House Workshop: Repairs and servicing performed efficiently without outsourcing (read more about progressive cavity pumps)

- Nationwide Support: Branches in Perth and Brisbane ensuring fast delivery and service

- Long-Term Reliability: Pumps and components designed to withstand heavy mining workloads

Partnering with MultiTorque guarantees reliable pumps, expert advice, and solutions that maximise uptime.

Maintenance and Support

MultiTorque provides comprehensive maintenance and support for all mining pumps:

- Routine inspection and component replacement

- Cleaning, lubrication, and hydraulic testing

- Seal and bearing replacements

- Performance evaluation and efficiency optimisation

- Expert guidance for installation, operation, and preventative maintenance

Proper maintenance using MultiTorque services extends pump life and ensures safe, efficient mining operations.

Why MultiTorque Stands Out

MultiTorque is a leading mining pump supplier because of:

- Proven Expertise: Over 15 years supplying and servicing industrial pumps for mining and industrial applications

- Technical Knowledge: Skilled in centrifugal, positive displacement, submersible, and custom pumps

- In-House Workshop Services: Efficient repair and maintenance performed onsite

- Custom Solutions: Tailored skid-mounted systems for complex mining operations

- Customer-Focused Service: Commitment to safety, reliability, and long-term partnerships (see more on industrial pump skid systems)

Mining companies choosing MultiTorque gain access to expert solutions, premium pumps, and reliable support to keep operations running smoothly.

Contact MultiTorque

For trusted mining pump suppliers in Australia, contact MultiTorque today. Our team will provide expert advice, help select the right pumps, and offer support to ensure your operations maintain efficiency and reliability.

📞 Phone: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: www.multitorque.com.au

🔗 LinkedIn: MultiTorque Industries

Trust MultiTorque for high-quality, reliable, and custom mining pump solutions that maximise performance and reduce downtime.