When it comes to efficiency, durability, and performance in pumping systems, Moyno pumps have earned a reputation as some of the most trusted progressive cavity pumps in the world. Designed to handle challenging fluids, abrasive slurries, and demanding industrial applications, Moyno pumps are widely used across mining, oil and gas, wastewater, food processing, and other sectors that require dependable fluid handling solutions.

At MultiTorque, we specialise in supplying, servicing, and repairing Moyno pumps for clients across Australia. With over 15 years of industry experience, our team understands the importance of choosing the right pumping equipment for long-term performance.

Why Choose Moyno Pumps?

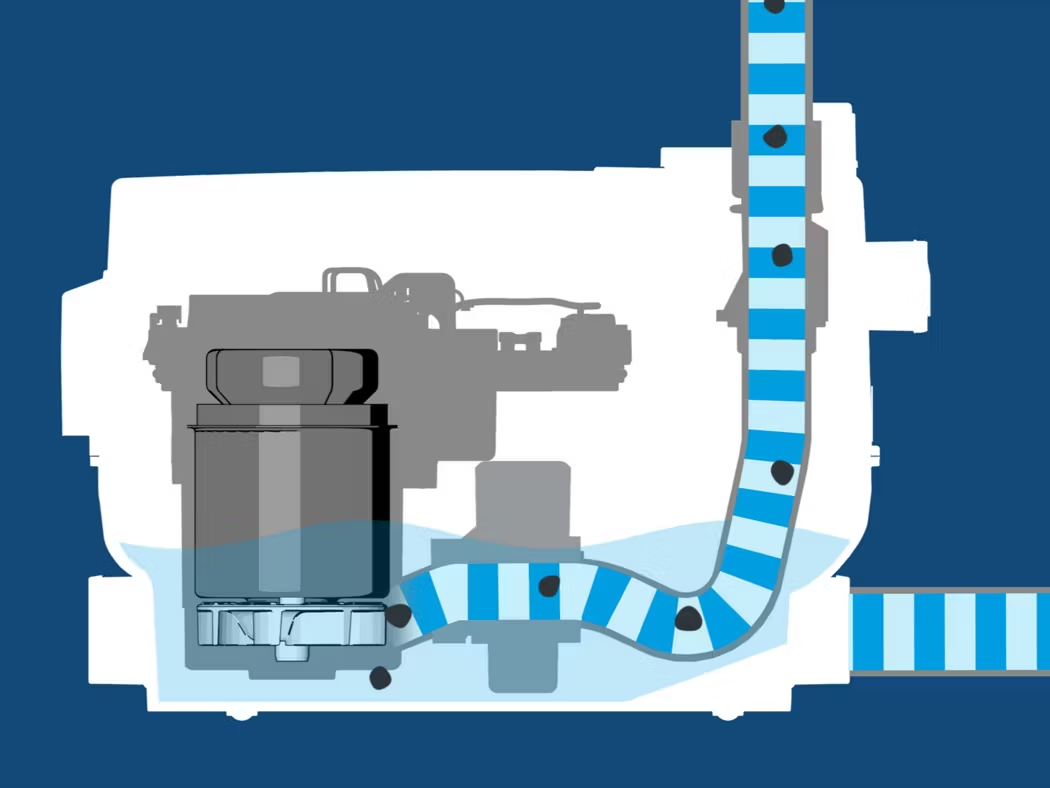

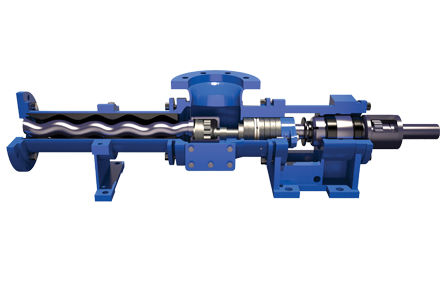

Moyno is a global leader in progressive cavity (PC) pump technology, offering solutions that deliver consistent performance where other pump designs often fail. Unlike centrifugal pumps that struggle with viscous or abrasive media, Moyno pumps excel in applications involving slurries, chemicals, and high solids content.

Some key benefits of Moyno pumps include:

- Durability – Engineered for tough environments, Moyno pumps are built to withstand abrasive materials.

- Versatility – Suitable for handling everything from wastewater to petroleum products.

- Low Maintenance – With fewer moving parts and reliable seals, Moyno pumps minimise downtime.

- Energy Efficiency – Designed for continuous, smooth operation, reducing operating costs.

- Customisation – A wide range of configurations are available to suit specific industrial needs.

This combination of reliability and adaptability has made Moyno a top choice for industries where fluid handling is critical to production.

Applications of Moyno Pumps

Moyno pumps are not “one size fits all.” They are designed to serve a variety of industries with specialised requirements. Some of the most common applications include:

1. Mining and Minerals Processing

In mining, pumps must withstand abrasive slurries and heavy-duty operations. Moyno pumps are ideal for transporting tailings, dewatering, and chemical dosing in mineral extraction.

2. Oil and Gas Industry

Moyno pumps handle viscous fluids such as crude oil, drilling mud, and other hydrocarbon-based materials with ease, making them a reliable choice for oilfield operations.

3. Wastewater Treatment

Municipalities and industrial plants rely on Moyno pumps to move sludge, sewage, and other challenging waste streams without clogging or breakdowns.

4. Food and Beverage

Hygienic versions of Moyno pumps are used in food production to handle viscous materials like sauces, syrups, and dairy products without compromising product quality.

5. Chemical Processing

Moyno pumps are widely used for chemical dosing, transferring corrosive fluids, and handling solvents safely and efficiently.

Moyno vs Other Pump Brands

At MultiTorque, we supply and service a wide range of pump brands, including Sulzer, Orbit, Wilden, Ebara, and Grundfos. While each brand has its strengths, Moyno pumps stand out in progressive cavity technology.

- Compared to centrifugal pumps, Moyno pumps are better suited for viscous and abrasive fluids.

- Unlike diaphragm pumps, which can struggle with continuous flow, Moyno pumps provide consistent output.

- In comparison with slurry pumps, Moyno pumps deliver smoother, low-pulsation handling of challenging materials.

This makes Moyno a preferred choice when reliability and precision are paramount.

Why Work with MultiTorque?

Choosing the right pump is only the first step. Ensuring that your pump is properly serviced and maintained is what keeps operations running efficiently. At MultiTorque, we provide:

- Supply of Moyno pumps – We source genuine Moyno products for industrial clients across Australia.

- Workshop-based repairs – All pump servicing and repairs are completed in-house by our experienced technicians.

- Custom solutions – Need a pump integrated into a trailer or specialised unit? We design and build custom pumping systems.

- Parts and spares – Access to seals, rotors, stators, and other critical Moyno components.

- Long-term support – With over 15 years of experience, we prioritise reliability and client relationships.

We don’t just sell pumps—we provide full lifecycle support to maximise your return on investment.

MultiTorque: Your Trusted Moyno Partner

Whether you’re in mining, wastewater, food processing, or oil and gas, Moyno pumps deliver long-term reliability. But like any industrial equipment, they perform best with expert servicing and genuine parts. That’s where MultiTorque comes in.

👉 Visit our website: www.multitorque.com.au

👉 Connect with us on LinkedIn: MultiTorque Industries

👉 Call us today: 1300 726 525

👉 Email: sales@multitorque.com

By partnering with MultiTorque, you get more than just a pump—you get a long-term solution tailored to your industry needs.

Final Thoughts

Moyno pumps have set the benchmark for progressive cavity technology, offering reliable, efficient, and versatile pumping solutions for demanding industries worldwide. From mining slurries to food-grade materials, Moyno pumps deliver unmatched performance.

At MultiTorque, we make it easy for Australian businesses to access, maintain, and optimise their Moyno equipment. With our in-house expertise, custom solutions, and commitment to long-term partnerships, we ensure that your pumping systems work at their best—day in, day out.

If you’re looking for Moyno pumps in Australia, talk to the experts at MultiTorque today.