NOV Pumps Australia: In Australia’s industrial landscape, reliable and high-performance pumping solutions are essential for mining, oil & gas, chemical processing, water management, and food & beverage industries. NOV pumps are globally recognised for their durability, efficiency, and versatility. At MultiTorque Industries, we supply, service, and repair NOV pumps across Australia, offering genuine parts and expert technical support to ensure your operations remain efficient and uninterrupted.

📞 Call 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

🔗 LinkedIn: MultiTorque Industries

Whether you are looking for NOV pumps Australia, servicing, or spare parts, MultiTorque provides tailored solutions that meet the demanding requirements of industrial applications.

Why Choose NOV Pumps

NOV pumps are designed for industrial environments that require reliable performance and minimal downtime. Key advantages of NOV pumps include:

- Robust Construction: Built to withstand abrasive and corrosive fluids.

- Versatile Applications: Suitable for a wide range of industrial processes, including oil, gas, and chemical transfer.

- Consistent Performance: Ensures steady flow and pressure even in challenging conditions.

- Low Maintenance: Modular design allows for efficient servicing and component replacement.

These features make NOV pumps a trusted choice for Australian industries seeking long-term reliability and efficiency.

Applications of NOV Pumps in Australia

NOV pumps are employed across a variety of industries to provide dependable fluid handling solutions:

Mining and Resource Industries

Mining operations require pumps capable of handling slurry, water, and chemicals in abrasive conditions. MultiTorque supplies pumps used in the mining industry designed to endure harsh environments and maintain consistent performance for continuous operations.

Oil & Gas Applications

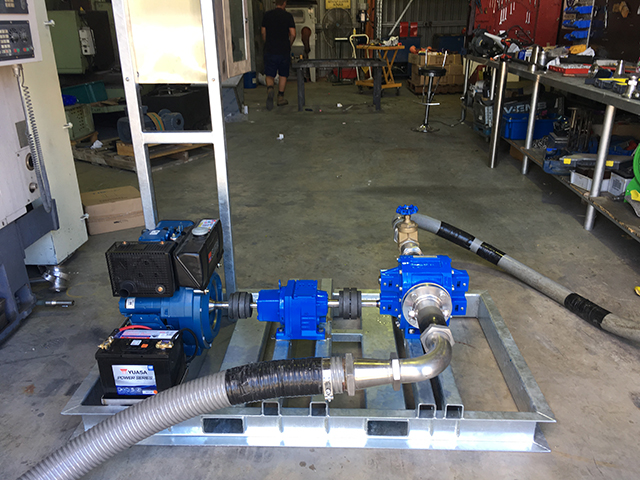

In oil and gas, NOV pumps are ideal for transferring hydrocarbons, drilling fluids, and other viscous liquids. MultiTorque also supplies pumping units for oil and gas applications to complement NOV solutions, ensuring operational reliability and efficiency.

Chemical Processing

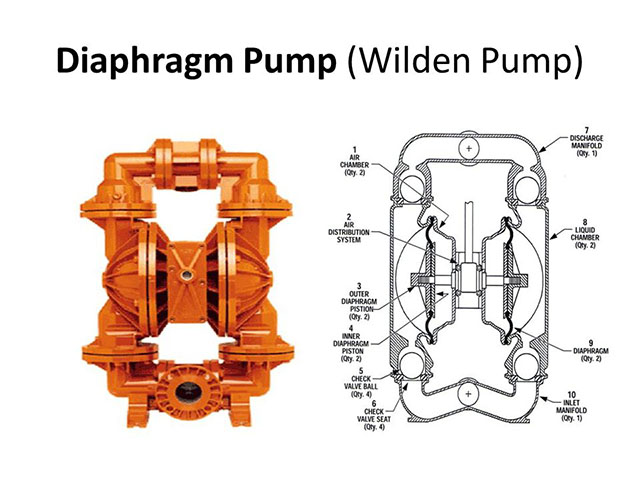

NOV pumps provide safe handling of corrosive and abrasive chemicals. Their precision engineering allows for accurate flow rates, smooth operation, and minimal risk of contamination, making them suitable for demanding chemical industries.

Water Management and Wastewater

NOV pumps are widely used in water and wastewater applications, from effluent transfer to water supply systems. MultiTorque also provides submersible pump solutions for oil and gas that integrate with NOV pumps for reliable fluid management in challenging environments.

Food & Beverage Industry

For food-grade applications, NOV pumps handle viscous liquids while maintaining hygiene and product integrity. MultiTorque ensures these pumps are serviced and maintained according to industry standards for safe operation.

MultiTorque: Your NOV Australia Partner

Selecting a reliable pump supplier is crucial to maintain efficiency and minimise downtime. MultiTorque provides comprehensive support for NOV pumps, including:

Genuine NOV Parts

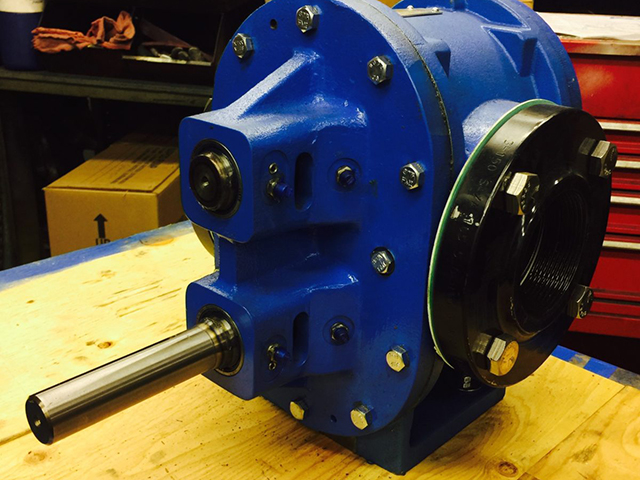

We stock original NOV pump components, including rotors, stators, and full assemblies, ensuring reliable performance and longevity of your equipment.

In-House Servicing

Our Perth and Brisbane workshops provide full in-house servicing for NOV pumps, guaranteeing quality repairs, fast turnaround times, and expert maintenance.

Technical Expertise

Our experienced technicians advise on pump installation, troubleshooting, and optimisation to ensure NOV pumps operate at peak efficiency.

Custom Pumping Solutions

MultiTorque collaborates with clients to design tailored NOV pump systems that meet specific industrial process requirements, improving reliability and operational efficiency.

For more insights into industrial pumping solutions, check out our Napco pump solutions article as a reference for how we handle multiple pump brands.

Advantages of Working With MultiTorque

Partnering with MultiTorque for NOV pumps in Australia provides several benefits:

- Reliability: Genuine parts and expert in-house servicing reduce downtime and maximise pump life.

- Industry Expertise: Decades of experience across mining, oil & gas, chemical, and water industries.

- Nationwide Support: With branches in Perth and Brisbane, we support clients throughout Australia.

- Tailored Solutions: Custom pump assemblies and maintenance plans designed specifically for your operational needs.

By choosing MultiTorque, your NOV pumps will operate efficiently, safely, and reliably, even in the most challenging industrial environments.

Industries Served by MultiTorque

- Mining & Resources: Efficiently handling slurry, water, and chemicals in harsh conditions.

- Oil & Gas: Safe and reliable fluid transfer in demanding applications.

- Water & Wastewater: Pumps for effluent, chemical dosing, and water supply.

- Chemical Processing: Handling abrasive and corrosive liquids with precision.

- Food & Beverage: Hygienic and reliable liquid transfer for food-grade applications.

MultiTorque ensures NOV pumps are properly installed, maintained, and serviced to meet the highest industry standards.

Contact MultiTorque for NOV Pumps Australia

For businesses seeking NOV pumps in Australia, MultiTorque provides genuine products, expert servicing, and technical support to ensure maximum efficiency and reliability.

📞 Call 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

🔗 LinkedIn: MultiTorque Industries

Partner with MultiTorque for NOV pump solutions Australia, ensuring your industrial operations run smoothly, safely, and efficiently.

NOV Pumps Australia NOV Pumps Australia NOV Pumps Australia NOV Pumps Australia NOV Pumps Australia NOV Pumps Australia NOV Pumps Australia