Industrial operations depend on efficiency, reliability, and durability. Whether it’s moving water, chemicals, slurry, or oil, pumps are at the heart of keeping systems flowing smoothly. When downtime occurs, productivity drops and costs rise. That’s why businesses across the country look for pumps industrial solutions that deliver consistent performance under demanding conditions.

At MultiTorque, we’ve spent over 15 years supplying, servicing, and repairing pumps for industries throughout Australia. From centrifugal pumps to progressive cavity pumps and custom pump systems, we deliver the right solution for your application. Our reputation for reliability, safety, and long-term client relationships makes us a trusted partner for businesses seeking pumps industrial solutions.

📞 Call us today on 1300 726 525

📧 Email sales@multitorque.com

🌐 Visit our website

🔗 Connect with us on LinkedIn

The Role of Pumps in Industrial Applications

In the industrial world, pumps are much more than mechanical equipment—they’re the backbone of processes that drive production. They are used for:

- Mining and resources – handling abrasive slurries and large volumes of water.

- Agriculture – transferring water for irrigation and livestock systems.

- Oil and gas – moving fluids under strict safety and performance requirements.

- Water treatment – ensuring clean and wastewater are processed effectively.

- Manufacturing – circulating chemicals, coolants, and process fluids.

Each industry requires a different approach, which is why choosing the right pumps industrial supplier is critical.

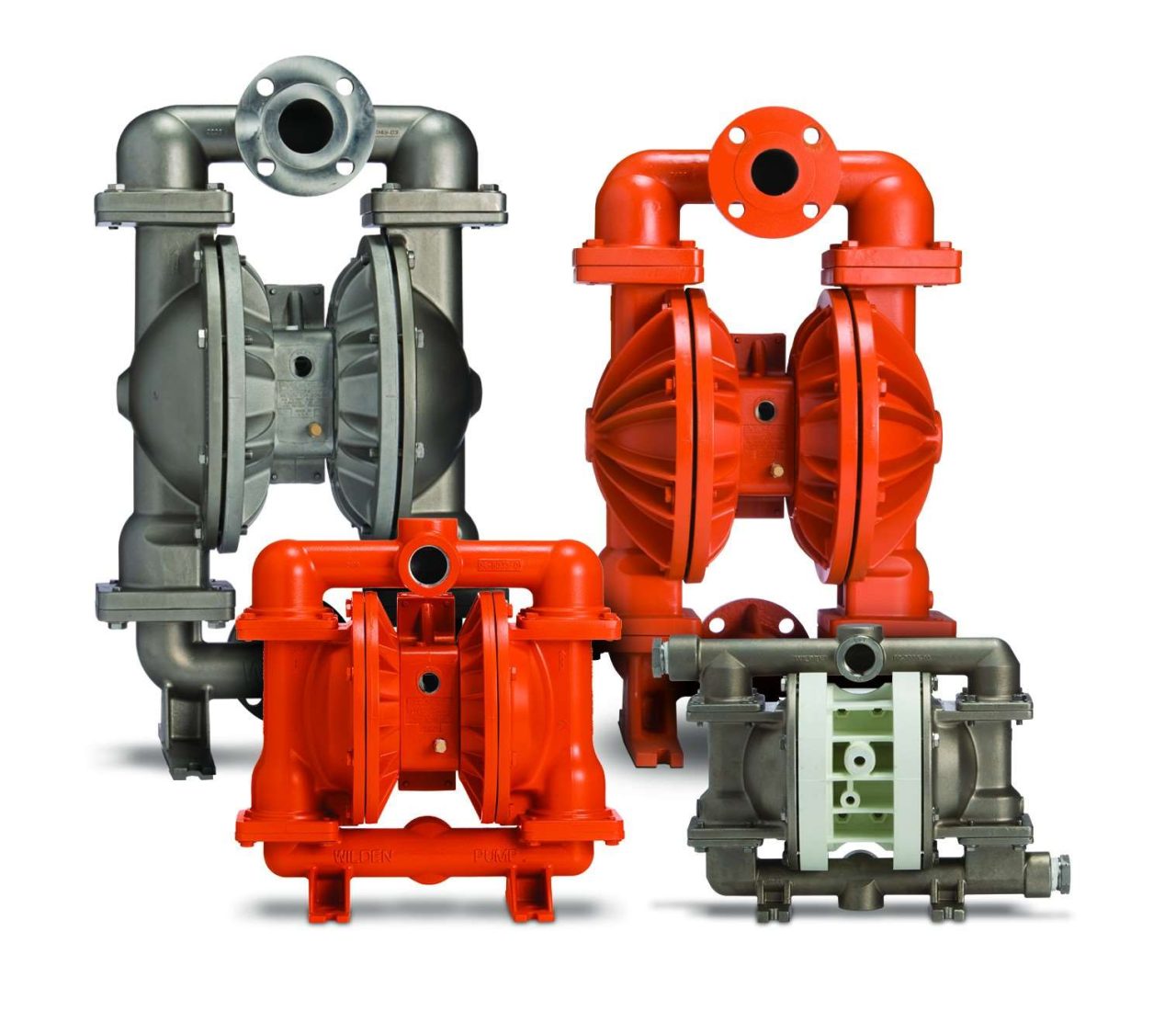

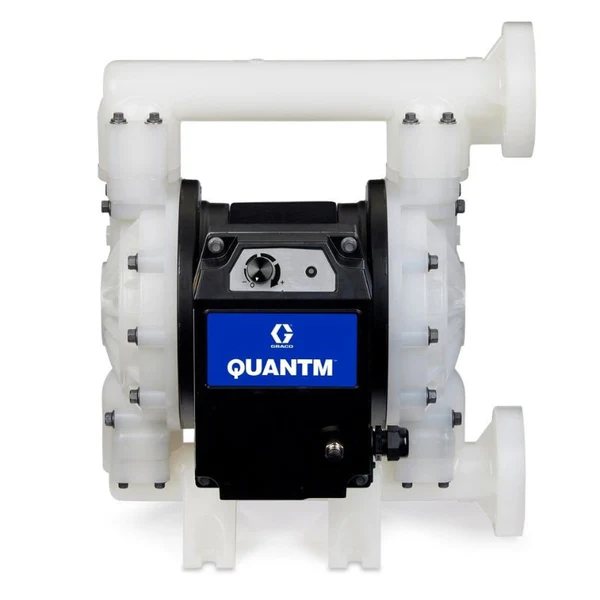

MultiTorque’s Range of Industrial Pumps

MultiTorque supplies pumps from globally trusted brands like Napco, NOV, Wilden, and Orbit. Our pumps industrial range covers multiple technologies to ensure the right fit for each application.

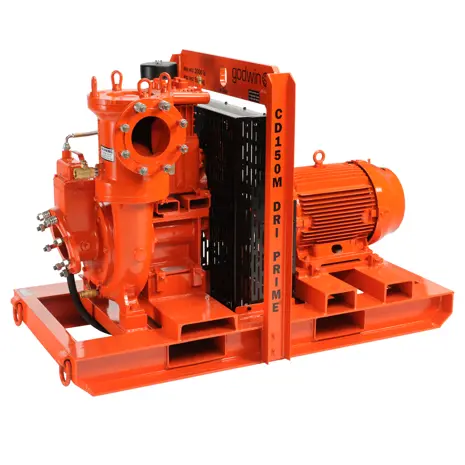

1. Centrifugal Pumps

These are the most widely used industrial pumps due to their efficiency in handling low-viscosity liquids such as water and chemicals. Centrifugal pumps are ideal for high-flow operations and are designed for long-term durability.

2. Progressive Cavity Pumps

When the fluid is viscous, abrasive, or contains solids, progressive cavity pumps are the answer. They provide a steady, reliable flow, even in harsh conditions. Perfect for mining, wastewater treatment, and heavy industrial uses.

3. Air and Gas Motor Starters

MultiTorque also supplies and services air and gas motor starters, which are essential in supporting pump performance in demanding industrial applications.

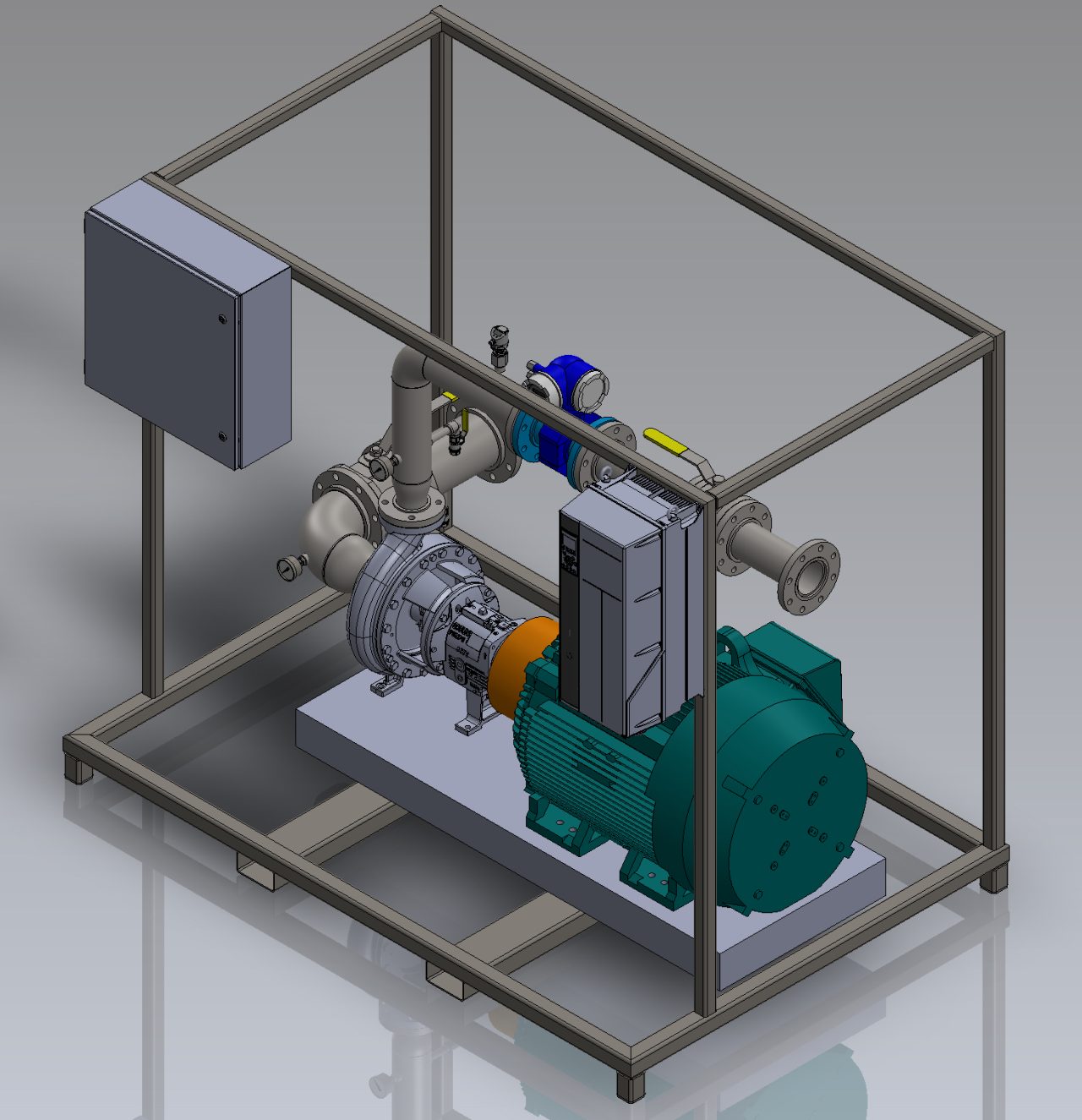

4. Custom Pump Systems

No two industries—or even two businesses—operate under the same conditions. That’s why MultiTorque designs and delivers custom industrial pump solutions, including mobile pumping setups with custom trailers. These bespoke systems are engineered to match your unique operational requirements.

Industrial Pump Services

At MultiTorque, we don’t just sell pumps—we keep them running. Our workshop-based services include:

- Preventive maintenance to extend pump life.

- In-house repairs for centrifugal and progressive cavity pumps.

- Component replacement and upgrades to improve performance.

- Testing and diagnostics to ensure peak efficiency.

- Custom modifications for unique industrial challenges.

While we don’t provide on-site repair services, our fully equipped workshops in Perth and Brisbane ensure that pumps are returned to clients quickly and in top condition.

Industries We Serve

MultiTorque provides pumps industrial solutions across Australia to industries such as:

- Mining & Resources – handling abrasive slurries and groundwater.

- Agriculture – irrigation systems and water transfer for farming operations.

- Oil & Gas – pumps built for safety and efficiency in tough environments.

- Water Treatment – solutions for both potable and wastewater applications.

- Manufacturing – precision pumps for chemicals, lubricants, and process fluids.

Our experience across these sectors allows us to recommend and supply pump systems tailored to specific operational challenges.

Why Choose MultiTorque for Pumps Industrial Solutions

Choosing the right supplier for pumps industrial is crucial to long-term success. MultiTorque offers:

- Proven Expertise – Over 15 years supplying pumps across Australia.

- Reliability – Trusted by industries that cannot afford downtime.

- Custom Solutions – Tailored pumping systems to meet unique needs.

- Safety and Compliance – Every pump is supplied and serviced with safety at the forefront.

- Long-Term Relationships – We provide ongoing support, not just one-time sales.

This commitment makes us one of the most reliable names for pumps industrial in Australia.

Benefits of MultiTorque’s Industrial Pumps

Our clients choose MultiTorque because our pumps and services deliver real results:

- Reduced downtime – With preventive maintenance and quick in-house servicing.

- Greater efficiency – Pumps designed to minimize energy and resource use.

- Lower total cost of ownership – Investing in reliable pumps reduces repair and replacement costs.

- Scalable solutions – From small-scale manufacturing to large mining operations, we supply pumps fit for purpose.

By combining quality products with expert technical knowledge, MultiTorque ensures that businesses across Australia can rely on their pumping systems day after day.

Supporting Australia with Smarter Pumping Solutions

Australia’s industries operate in some of the toughest conditions in the world. From the dust and heat of mining regions to the corrosive challenges of coastal environments, pumps must be built to endure. MultiTorque provides pumps industrial solutions that are:

- Durable – Designed to withstand abrasive and corrosive materials.

- Efficient – Built to reduce energy use and maximize productivity.

- Adaptable – Customizable to specific industry demands.

- Supported – Backed by expert servicing and technical advice.

This is why MultiTorque is trusted nationwide for pump supply, service, and repair.

Contact MultiTorque – Pumps Industrial Specialists

If your business is searching for pumps industrial solutions in Australia, MultiTorque is here to help. With a wide range of pumps, in-house servicing, and custom systems, we provide the expertise and reliability your industry demands.

📞 Call us today on 1300 726 525

📧 Email sales@multitorque.com

🌐 Visit our website

🔗 Connect with us on LinkedIn

Choose MultiTorque for your pumps industrial needs and gain a partner committed to reliability, safety, and long-term performance