Mining is one of Australia’s most demanding industries, where reliability, safety, and performance are non-negotiable. At the heart of many mining operations is an often-overlooked but absolutely critical component: the gold mine pump. Whether it’s dewatering shafts, transferring slurry, or maintaining water balance in remote and challenging environments, pumps keep mining operations moving. Without them, delays, equipment damage, or even safety hazards can occur.

MultiTorque, with over 15 years of expertise in pump supply, servicing, and repair, is proud to provide tailored pumping solutions that keep mines operating smoothly across the country. In this article, we’ll explore the role of gold mine pumps, their importance in the mining sector, and why MultiTorque is a trusted partner for reliable, long-term solutions.

📞 Call us on 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

🔗 Connect with us on LinkedIn

The Role of Gold Mine Pumps

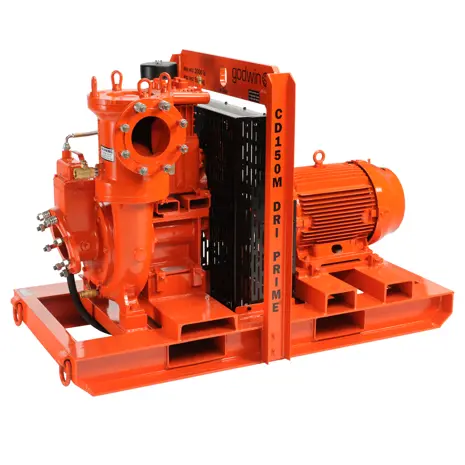

Gold mining is a high-pressure industry that involves moving water, slurry, and other fluids in challenging environments. A gold mine pump must withstand abrasive materials, unpredictable conditions, and continuous operation. Typical applications include:

- Dewatering: Keeping underground tunnels and open-pit mines dry and safe.

- Slurry handling: Transferring mixtures of ore, water, and abrasive particles.

- Water supply and removal: Managing water resources within mining sites.

- Process support: Assisting in mineral processing where fluids must be moved consistently and safely.

These pumps are designed not only for efficiency but also for resilience. Downtime in mining is costly, and the right pump ensures operations run without disruption.

Challenges of Gold Mine Pumping

Working in mining environments presents unique obstacles for pumping systems:

- Abrasive materials – Slurry and ore-laden fluids wear down pumps quickly if not properly designed.

- Harsh conditions – Extreme temperatures, dust, and remote locations demand rugged equipment.

- Continuous duty – Pumps must run for extended periods with minimal maintenance downtime.

- Energy efficiency – Mining is energy-intensive, so pumps must deliver high performance while minimizing power consumption.

MultiTorque addresses these challenges by supplying pumps designed for durability, efficiency, and adaptability. Our solutions help reduce operating costs while increasing uptime and safety.

Types of Pumps Used in Gold Mining

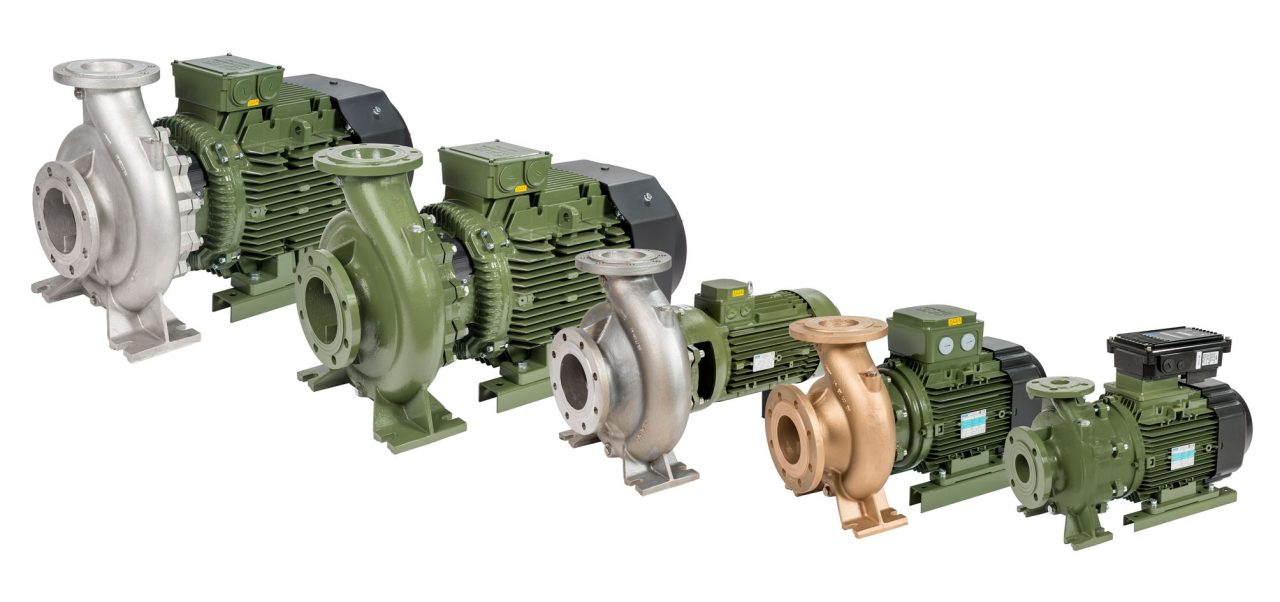

Different mining tasks require specialized pumping equipment. Some of the most common include:

- Centrifugal pumps – Ideal for moving large volumes of water quickly, often used for dewatering.

- Progressive cavity pumps – Suited for viscous, abrasive slurries, offering steady flow and low pulsation.

- Diaphragm pumps – Air-operated and versatile, great for challenging applications with abrasive fluids.

- Submersible pumps – Used directly in flooded areas, efficient for underground and pit dewatering.

MultiTorque supplies, services, and repairs leading pump brands, ensuring our mining clients always have access to equipment tailored to their needs.

Why Choose MultiTorque for Gold Mine Pump Solutions?

For more than 15 years, MultiTorque has partnered with mining companies across Australia, delivering pump solutions built on reliability and safety. Here’s what sets us apart:

- Comprehensive expertise – From centrifugal to progressive cavity pumps, we work with all major pump types.

- Trusted brands – We service and supply pumps from respected names like NOV, Wilden, Napco, Orbit, and more.

- Custom solutions – No mine is the same. MultiTorque can design and fabricate custom pump skids, trailers, or mobile pumping units to suit unique mining conditions.

- In-house workshop repairs – While we don’t offer on-site pump repairs, our fully equipped workshops in Brisbane and Perth handle complete servicing, overhauls, and refurbishments.

- Long-term reliability – We focus on building relationships with our clients, ensuring ongoing support and trusted performance.

Case Study: Gold Mine Pump Efficiency in Action

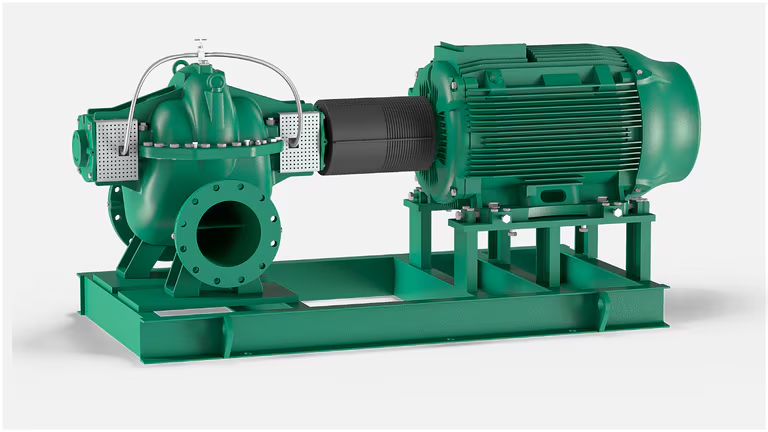

One of our clients in Western Australia required a high-capacity dewatering solution for their gold mine operation. The challenge? Their existing system was inefficient and suffered frequent breakdowns due to abrasive slurry.

MultiTorque stepped in with a tailored solution:

- A combination of centrifugal and progressive cavity pumps.

- A custom-built mobile pumping unit mounted on a trailer for easy relocation.

- Heavy-duty materials designed to withstand abrasive wear.

The result:

- Downtime was reduced by 40%.

- Maintenance costs were cut significantly.

- Productivity increased thanks to reliable, continuous dewatering.

This is just one example of how the right gold mine pump system makes all the difference.

Supporting the Mining Industry with More Than Pumps

Beyond supplying and servicing pumps, MultiTorque also provides:

- Spare parts sourcing for pump maintenance.

- Air and gas motor starters for mining equipment.

- Custom borehole pump trailers for specific site requirements.

- Fire suppression fittings and fire hose accessories to support safety compliance.

By offering a wide range of solutions, we ensure mines have everything they need to operate smoothly and safely.

Related Reading

If you’d like to explore more about MultiTorque’s pumping solutions, check out these in-depth resources:

- Fire Hose Accessories

- Fire Suppression Fittings

- Mobile Pumping Unit

- Irrigation Skid

- Industrial Pumps Australia

- Pump Systems Australia

- Irrigation Pump Systems

- IR Pumps

- Industrial Irrigation Pump

- Pumps Industrial

- Pump Solutions Australia

- Pump Supplier QLD

- Wilden Pneumatic Pump

MultiTorque: Your Partner in Mining Success

The success of a mining operation depends on more than just machinery — it relies on systems that keep working under pressure. A gold mine pump from MultiTorque isn’t just a piece of equipment; it’s a solution backed by expertise, reliability, and long-term partnership.

If you’re looking for dependable pumping solutions tailored to the mining industry, MultiTorque is ready to help.

📞 Call us on 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

🔗 Connect with us on LinkedIn