Fire safety isn’t just a compliance measure — it’s an investment in reliability, operational uptime, and peace of mind. Across Australia’s demanding sectors like mining, transport, logistics, marine, and energy, businesses need protection systems they can trust. That’s where FirePro solutions lead the way.

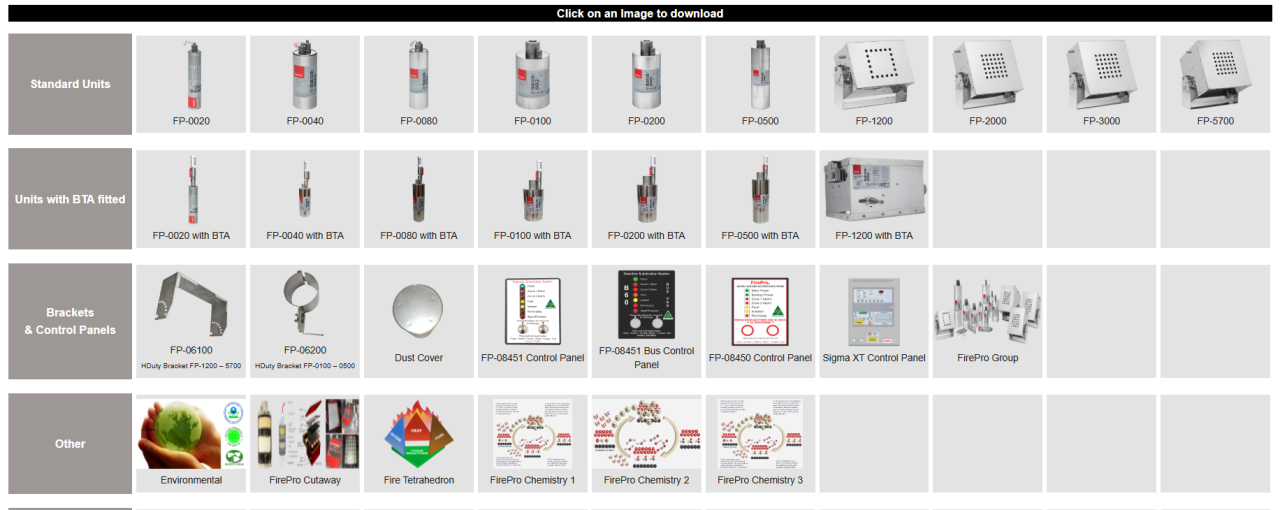

As an official FirePro distributor, MultiTorque provides world-class aerosol fire suppression systems that combine innovative technology, compact design, and environmentally safe performance — redefining how industries safeguard people and equipment.

What Are FirePro Solutions?

FirePro solutions are pre-engineered condensed aerosol fire suppression systems designed to extinguish fires at the chemical level. Unlike traditional systems that rely on water, foam, or high-pressure gas, FirePro works by interrupting the fire’s combustion chain reaction, stopping flames instantly and safely.

Activated thermally or electrically, FirePro releases a potassium-based aerosol that fills the protected space, binding to free radicals in the fire and preventing it from reigniting. This unique process makes FirePro one of the most reliable and efficient suppression systems available in Australia today.

Certified Safety and Performance

All FirePro solutions are certified to AS 4487 (Aerosol Systems) and AS 5062 (Mobile Plant Fire Protection) — ensuring full compliance with Australian standards for both mobile and fixed systems.

Each unit is rigorously tested to perform in extreme heat, vibration, and environmental conditions, making FirePro ideal for industries operating in Australia’s toughest terrains — from underground mines to offshore facilities.

Why Choose FirePro Solutions?

1. Environmentally Friendly Fire Suppression

FirePro’s active agent has zero ozone depletion potential (ODP) and zero global warming potential (GWP). It’s non-toxic, non-corrosive, and completely safe for sensitive electrical equipment, making it an ideal choice for environmentally conscious operations.

2. Compact, Lightweight, and Modular

Traditional fire systems require bulky cylinders, high-pressure piping, and regular refills. FirePro solutions eliminate that. Their modular units are compact and lightweight, making installation simple — even in confined areas.

3. Low Maintenance and Long Lifespan

FirePro systems operate without pressurised gas, significantly reducing maintenance costs. With a service life of up to 15 years, you can count on consistent protection with minimal upkeep.

4. Rapid and Reliable Activation

Once activated, FirePro releases a fine aerosol cloud that chemically interrupts combustion. It doesn’t deplete oxygen, cause water damage, or leave corrosive residue — ensuring total safety for personnel and equipment alike.

5. Versatile Applications

From fixed industrial systems to mobile and marine fire suppression, FirePro solutions are adaptable to almost any environment, offering unmatched protection flexibility.

Applications of FirePro Solutions

MultiTorque delivers FirePro solutions tailored to Australia’s most vital industries:

Mining and Mobile Plant

Mining environments face constant fire risks from electrical faults and hydraulic systems. FirePro protects haul trucks, dozers, excavators, and processing plants, ensuring safety and operational uptime in high-risk environments.

Marine and Offshore

Compact, corrosion-resistant, and self-contained — FirePro solutions are ideal for engine compartments, fuel storage, and control panels aboard ships, ferries, and offshore rigs.

Transport and Logistics

Protect fleet vehicles, buses, and heavy transport assets from engine and electrical fires with low-maintenance FirePro systems designed for mobile use.

Industrial and Manufacturing

In factories and processing plants, FirePro safeguards switchboards, battery systems, conveyor motors, and control cabinets, keeping critical operations safe and uninterrupted.

Energy, Power, and Renewables

With the growing demand for battery energy storage systems (BESS) and transformer protection, FirePro solutions offer instant suppression without compromising equipment performance or lifespan.

How FirePro Works

FirePro operates on a simple yet powerful principle: chemical interference.

When activated, FirePro’s proprietary FPC compound reacts to create a dense aerosol that interacts with the flame’s free radicals, halting the chemical reactions that sustain fire.

The result is near-instant suppression without oxygen depletion or harmful side effects. This makes FirePro safe for enclosed spaces and ideal for protecting electronics, engines, and sensitive machinery.

FirePro vs Traditional Fire Systems

| Feature | FirePro Solutions | Traditional Systems |

|---|---|---|

| Suppression Agent | Condensed aerosol | Water/Foam/Gas |

| Maintenance | Low | High |

| Oxygen Depletion | No | Sometimes |

| Environmental Impact | Zero ODP / GWP | Potentially harmful |

| Installation | Compact modules | Complex pipework |

| Ideal Applications | Fixed & mobile | Mostly fixed |

Why Choose MultiTorque for FirePro Solutions

With over 15 years of experience in supplying, servicing, and supporting industrial and mining fire safety systems, MultiTorque is your trusted partner for FirePro solutions in Australia.

Operating across Brisbane, Sydney, Perth, and New Zealand, MultiTorque provides tailored system design, professional installation support, and expert after-sales service for industries where reliability matters most.

We proudly serve sectors including mining, oil & gas, logistics, civil construction, marine, agriculture, and industrial manufacturing, ensuring every client has access to safe, compliant, and sustainable fire protection.

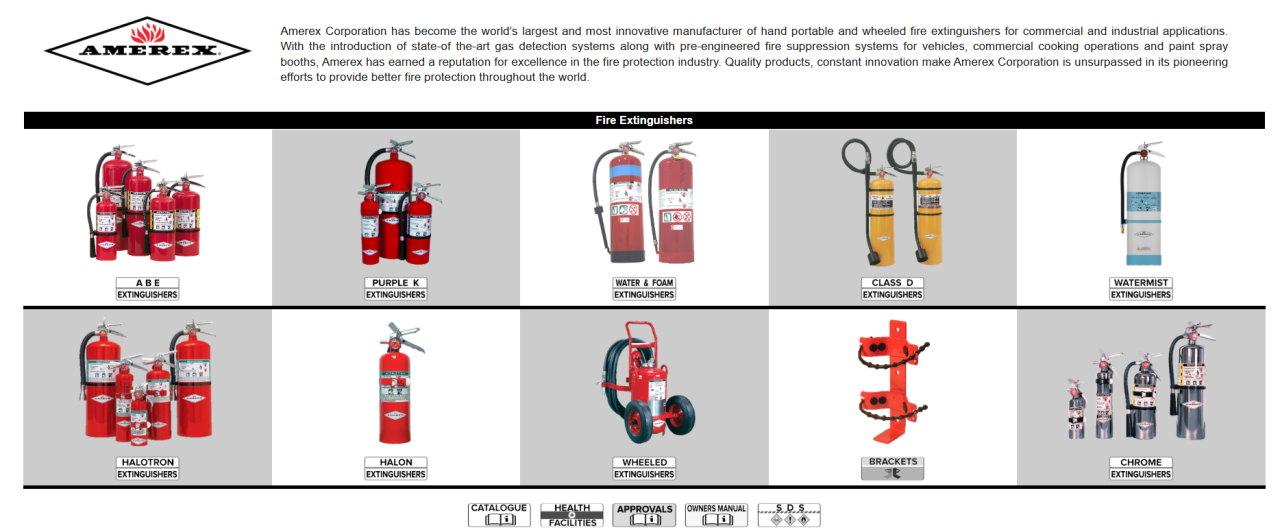

FSEquip – Supplying Fire Suppression Equipment for Every Need

As part of the MultiTorque Group, FSEquip provides an extensive range of fire suppression and protection equipment — including gas, foam, and aerosol systems for mobile, fixed, and marine applications.

Explore our catalogue and enhance your safety systems today:

🔗 Visit: https://fsequip.au/

Contact MultiTorque for FirePro Solutions Today

Protect your people, equipment, and assets with FirePro solutions from Australia’s trusted industrial safety specialists. Whether you’re in mining, transport, or energy, MultiTorque has the expertise and technology to keep your operations safe.

📞 Call: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: https://www.multitorque.com.au/

🔗 Connect on LinkedIn: MultiTorque Industries