Seepex Progressive Cavity Pump: Reliable Solutions for Efficient Fluid Handling 2025

When it comes to handling challenging fluids with precision and durability, the Seepex progressive cavity pump stands out as a preferred choice in various industries. Designed to transport highly viscous, abrasive, or shear-sensitive materials, Seepex pumps provide long-term reliability, low pulsation flow, and reduced maintenance costs.

In this article, we’ll explore what makes Seepex progressive cavity pumps exceptional, their core features, advantages, applications, and how MultiTorque supports customers in selecting and sourcing the right pump solutions for their operations.

What is a Seepex Progressive Cavity Pump?

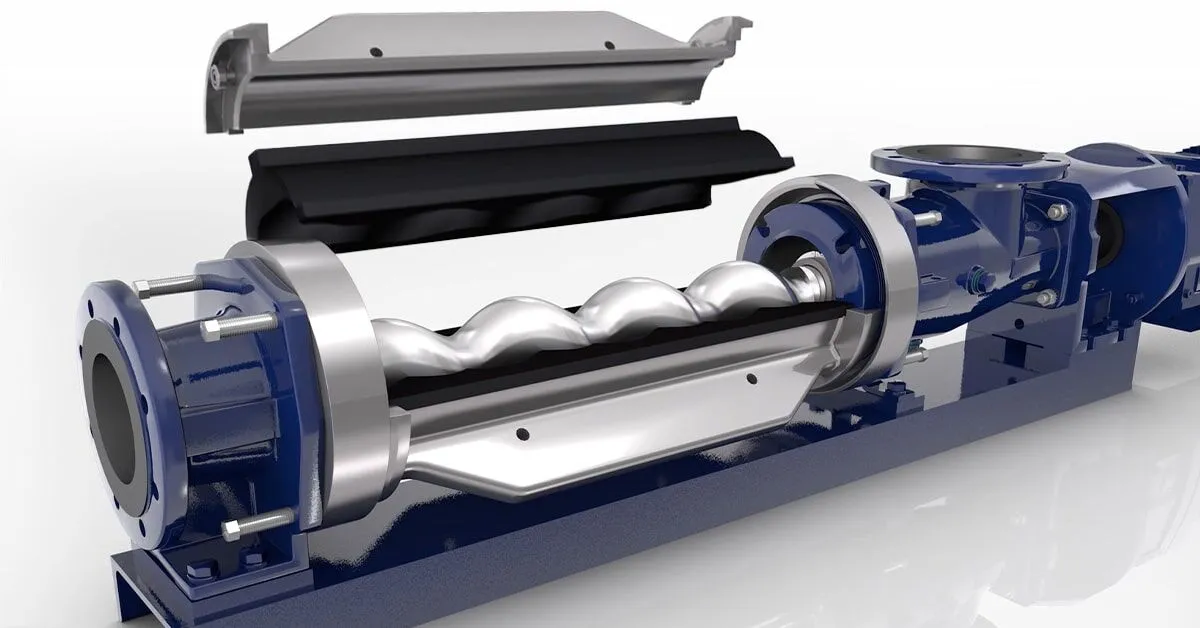

A progressive cavity pump, also known as a PC pump, operates using a rotor and stator mechanism to move fluid through the pump in a continuous, sealed cavity. The design ensures minimal pulsation and is ideal for transferring delicate or difficult fluids.

Seepex, a globally recognised manufacturer of PC pumps, is known for its innovation and engineering precision. Their progressive cavity pumps feature modular design systems, high-quality materials, and customisable components tailored to each industry’s needs.

Key Features of Seepex Progressive Cavity Pumps

1. Modular Construction:

Seepex pumps are built with interchangeable components, making maintenance easier and more cost-effective.

2. Low Pulsation Flow:

The rotor-stator mechanism delivers a steady, consistent flow, reducing the risk of fluid degradation—ideal for sensitive fluids.

3. Wide Viscosity Range:

Capable of handling everything from water-like liquids to thick sludges and pastes.

4. High Suction Lift:

These pumps maintain high suction capability even in low NPSH environments.

5. Accurate Dosing and Metering:

Perfect for chemical processing and dosing applications where precision is critical.

6. Customised Configurations:

Seepex offers a wide range of series—such as the BCSO, BNM, and D ranges—engineered for specific industries and needs.

Benefits of Using a Seepex Progressive Cavity Pump

1. Reduced Downtime

Modular maintenance and quick part replacements mean less disruption to your operations.

2. Extended Service Life

Superior rotor and stator materials resist wear, improving the pump’s operational longevity.

3. Energy Efficiency

Smooth and consistent flow rates help reduce power usage compared to other positive displacement pumps.

4. Flexible Applications

Seepex pumps are suitable across industries like mining, wastewater, food and beverage, oil & gas, chemical processing, and agriculture.

5. Cost Savings Over Time

Though premium in price, Seepex pumps offer exceptional value due to their long lifespan and minimal unplanned servicing needs.

Industries That Use Seepex Progressive Cavity Pumps

1. Wastewater Treatment:

For sludge handling, thickened slurry transfer, and polymer dosing.

2. Food & Beverage:

To move fruit purees, syrups, sauces, and beverages without damaging the product.

3. Mining & Minerals:

Capable of pumping abrasive slurry, dewatering, and backfilling applications.

4. Oil & Gas:

Transferring drilling muds, polymers, and emulsions with reliability in harsh conditions.

5. Agriculture:

For transferring manure, feed solutions, and nutrient-rich liquids.

6. Chemical Processing:

Precise metering of acids, bases, and solvents where accuracy is key.

Choosing the Right Seepex Pump Model

MultiTorque’s expert team helps customers select the best model based on fluid properties, flow rate, pressure needs, and environmental conditions. Some of the most popular Seepex series include:

- BN Series: For general applications with modular configuration.

- MD Series: Designed for metering and dosing.

- CS Series: Built for hygienic applications, suitable for food and beverage or pharmaceuticals.

- T and D Series: High-performance pumps for dewatered sludge and high-pressure applications.

We supply genuine Seepex parts, offer consultation on system upgrades, and ensure compatibility with existing infrastructure.

Maintenance & Service Considerations

Seepex progressive cavity pumps are designed with serviceability in mind. Stator and rotor wear can be easily monitored, and parts can be swapped without dismantling the entire unit. This reduces labour costs and limits production downtime.

Additionally, MultiTorque offers workshop repairs, part sourcing, and maintenance kits for Seepex pumps. While we don’t provide on-site repairs, our Perth and Brisbane facilities are equipped to handle complete rebuilds, part replacements, and custom modifications.

Why Buy Seepex Pumps Through MultiTorque?

At MultiTorque, we’re more than just suppliers—we’re pump specialists with 15+ years of experience helping Australian businesses find the right pumping solutions. As a trusted supplier of progressive cavity pumps, we:

- Source and supply genuine Seepex parts

- Offer expert technical advice

- Conduct workshop-based pump servicing

- Provide aftermarket options when cost-efficiency is key

- Maintain long-term client relationships built on trust and quality

Whether you’re replacing an existing Seepex pump or building a new fluid handling system, we’ll support you from specification through to supply and servicing.

Contact MultiTorque Today

Looking for a reliable supplier of Seepex progressive cavity pumps in Australia? Need help choosing the right model or finding spare parts?

📞 Call us at 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

🔗 Connect on LinkedIn