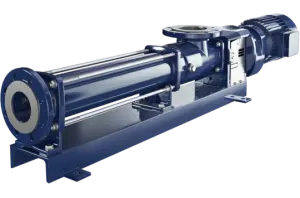

Seepex Progressive Cavity Pump: A Leader in Precision Fluid Handling 2025

When it comes to efficient, low-pulsation fluid transfer in industrial applications, the Seepex progressive cavity pump stands out as one of the most reliable and advanced choices on the market. Engineered in Germany and trusted around the world, Seepex pumps are built for performance, precision, and durability—making them ideal for a wide range of industries, from wastewater and mining to food production and chemical processing.

At MultiTorque, we supply, service, and support Seepex pumps across Australia, offering fast turnarounds, genuine parts, and technical expertise from our locations in Perth and Brisbane.

What Is a Seepex Progressive Cavity Pump?

A progressive cavity pump is a type of positive displacement pump that moves fluid through a sequence of fixed cavities. These cavities are formed between a helical rotor and a double-helix stator, allowing the pump to gently push product through with low shear and minimal pulsation.

Seepex is known for their innovation in this category, offering smart modular designs, customizable pump packages, and Industry 4.0-ready solutions.

Why Choose a Seepex Pump?

✅ Low Pulsation, High Precision

Seepex pumps deliver consistent, non-turbulent flow, making them ideal for handling shear-sensitive fluids such as polymers, sludge, or food products.

✅ High Viscosity and Solids Tolerance

With the ability to pump highly viscous materials and fluids containing solids, Seepex pumps outperform traditional centrifugal pumps in many challenging applications.

✅ Modular Design

Seepex pumps are modular in design, which allows for faster maintenance, easy part replacement, and cost-effective upgrades.

✅ Energy Efficiency

Their progressive cavity design ensures a steady flow rate and reduced energy consumption—especially valuable in continuous process environments.

Common Applications for Seepex Progressive Cavity Pumps

Seepex pumps are used across a wide array of industries, including:

1. Wastewater Treatment

Seepex pumps are commonly used for sludge transfer, polymer dosing, and dewatering systems, providing reliable and clog-free operation.

2. Mining and Dewatering

The ability to handle abrasive slurries and viscous tailings makes Seepex pumps well-suited for mine dewatering and slurry transfer systems.

3. Food and Beverage

With models made from hygienic stainless steel and FDA-compliant components, Seepex progressive cavity pumps are used to pump sauces, fruit pulp, dairy, and beverage ingredients without compromising product integrity.

4. Chemical and Industrial

Seepex pumps excel in chemical metering, paint production, polymer handling, and any fluid transfer that requires precision dosing and durability.

Seepex Product Lines Available at MultiTorque

Some of the most popular Seepex pump ranges include:

- BN Series – Standard pumps for a wide range of industries

- MD Series – Metering pumps for precise fluid dosing

- BT Series – Hopper pumps for viscous or non-flowable media

- TSE Series – Twin screw pumps for hygienic applications

- CS Series – Pumps designed for hygienic and clean-in-place processes

Whether you’re dealing with thick slurries or sensitive ingredients, there’s a Seepex progressive cavity pump designed for your application.

Why MultiTorque?

MultiTorque is one of Australia’s trusted suppliers and service providers for Seepex pumps and parts. Here’s why customers across mining, municipal, food, and agriculture industries trust us:

- Fast sourcing of Seepex models and OEM parts

- Workshop and field service teams in Brisbane and Perth

- Pump diagnostics and failure reports

- Custom pump system design and fabrication

- Onsite installations and commissioning

We offer a full lifecycle support package, from sales and repairs to rebuilds and upgrades.

🌐 Visit www.multitorque.com.au

Seepex Pump Maintenance and Servicing

Seepex’s modular construction makes maintenance simple, but it still requires skilled hands and OEM parts. At MultiTorque, we provide:

- Rotor and stator replacement

- Gearbox checks

- Seal servicing

- Pump performance testing

- Rebuilds and retrofits

We only use genuine Seepex spare parts to maintain optimal performance and compliance with warranty requirements.

Custom Pump Skids Featuring Seepex Technology

Need a complete pumping solution? MultiTorque can build turnkey pump skids using Seepex progressive cavity pumps, tailored for your site conditions. These mobile or fixed systems can include:

- Integrated VFDs (variable frequency drives)

- Flow meters and smart controls

- Custom piping and valving

- Stainless steel base frames for hygiene-sensitive industries

Whether it’s an underground mine, remote dewatering site, or food-grade facility, we engineer solutions that deliver efficiency and reliability.

The Future of Pumping: Seepex Smart Technology

Many Seepex pumps are available with Smart Conveying Technology (SCT), which reduces downtime by making maintenance faster and easier. Seepex has also developed IoT-enabled systems, allowing for:

- Remote condition monitoring

- Predictive maintenance alerts

- Energy usage analytics

Pairing Seepex’s smart pumps with MultiTorque’s technical support ensures maximum uptime and performance.

Final Thoughts

The Seepex progressive cavity pump is the ultimate solution when it comes to accurate, efficient, and durable fluid handling. Whether you need precision dosing in a food facility or heavy-duty sludge transfer in wastewater treatment, Seepex pumps deliver where others fall short.

Partner with MultiTorque to get the most out of your Seepex investment. From selection and supply to maintenance and custom solutions, we’re your one-stop shop for progressive cavity pump support in Australia.

📞 Contact Us Today

Looking to purchase, upgrade, or service your Seepex progressive cavity pump?

👉 Call us on 1300 726 525 or email sales@multitorque.com

📌 Learn more at: www.multitorque.com.au

🔗 Follow us on LinkedIn for updates and behind-the-scenes pump projects.