Rotor Stator Pump Parts Australia’s #1 Quality Supplier OEM and Aftermarket Parts

What Are Rotor Stator Pump Parts?

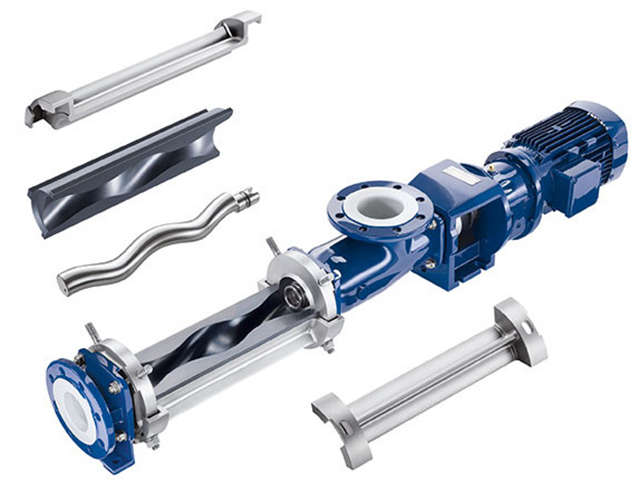

Rotor stator pumps are a type of progressive cavity pump, prized for their ability to handle viscous, abrasive, or shear-sensitive fluids. At the heart of this pump technology is the rotor and stator combination, which forms the essential pumping mechanism. Understanding rotor stator pump parts is vital for engineers, maintenance teams, and procurement professionals working in industries such as mining, wastewater, oil & gas, and food processing.

Key Rotor Stator Pump Components

1. Rotor

The rotor is a single-threaded helical screw, typically made of chrome-plated or stainless steel. It rotates eccentrically inside the stator, creating cavities that push fluid through the pump. Rotors must be wear-resistant and precisely machined for optimal sealing and minimal slip.

2. Stator

The stator is the molded elastomer component that houses the rotor. It features a double-helix geometry and is often made from materials like nitrile, EPDM, or Viton. The elastomer’s compatibility with your pumped fluid determines how long the stator lasts before it needs replacing.

3. Coupling Rod & Joints

Because the rotor’s motion is not concentric, a flexible coupling rod connects it to the motor. These rods are paired with cardan joints, pin joints, or gear joints, which absorb torque and allow for movement. Worn joints can cause vibration, misalignment, and even total pump failure.

4. Shaft Seals

To prevent leaks at the drive end, mechanical seals or gland packing are installed. Mechanical seals are ideal for high-pressure applications or toxic fluids, while gland packing is often used in more accessible, service-friendly systems.

5. Suction and Discharge Housings

These structural parts direct the fluid in and out of the rotor-stator cavity. In abrasive applications like slurry or grout pumping, these parts must be built from wear-resistant materials.

6. Drive Shaft and Bearings

The drive shaft transfers motion from the motor to the rotor, and is supported by bearings that maintain alignment. If the bearings wear out, you’ll see increased energy use, vibration, and part degradation.

Rotor and Stator Material Options

Rotor stator pump parts are available in a range of material combinations to handle specific chemicals and temperature ranges:

- Rotors: Stainless steel, chrome-plated steel, Hastelloy

- Stators: NBR (nitrile), EPDM, FKM (Viton), PTFE blends

Matching the right material to your application improves performance and reduces replacement frequency.

Signs Your Rotor Stator Pump Parts Need Replacing

To avoid costly downtime, keep an eye out for these warning signs:

- Reduced flow or pressure

- Excessive vibration

- Fluid leakage

- Heat generation

- Noisy operation

Early intervention can prevent further damage to expensive components like the stator or drive shaft.

OEM vs Aftermarket Rotor Stator Pump Parts

Choosing between OEM and aftermarket parts comes down to performance and cost. High-quality aftermarket rotor stator pump parts can offer equivalent performance at a lower cost. Ensure compatibility with popular pump models such as:

- Netzsch NEMO®

- Moyno®

- Seepex®

- PCM®

At MultiTorque, we help customers source rotor stator pump parts for both OEM and aftermarket options, ensuring compatibility, quality, and speed of delivery.

Why Choose MultiTorque for Rotor Stator Pump Parts?

- Fast sourcing of both standard and hard-to-find parts

- Local Australian support with shipping to all states

- Experienced team offering product recommendations

- Quality assurance on elastomers, metals, and sealing systems

We understand that every rotor stator system is a little different — especially with varying flow rates, pressures, and fluid types. That’s why we tailor our parts sourcing to suit your specific application.

Final Thoughts

Rotor stator pump parts are the lifeblood of progressive cavity systems. From food-grade stators to heavy-duty slurry rotors, every component plays a crucial role in keeping your system running efficiently. Whether you’re after a simple stator replacement or a full rotor and coupling rod assembly, sourcing high-quality, compatible parts will ensure long-term performance.

For expert advice or to place an order, reach out to MultiTorque or connect with us via LinkedIn.

Contact us on 1300 726 525 or email sales@multitorque.com