Rotary Lobe Pump: Powerful Flow for Thick and Shear-Sensitive Fluids 2025

If you’re moving thick fluids, abrasive slurries, or delicate ingredients, a rotary lobe pump could be the missing piece in your process. Known for their gentle action, low shear, and sanitary design, rotary lobe pumps are a staple in industries where fluid integrity, hygiene, and performance matter most.

At MultiTorque, we supply and service rotary lobe pumps that keep Australian industries running—whether it’s dairy on a production line, molasses on a farm, or chemical concentrate in a plant.

What Is a Rotary Lobe Pump?

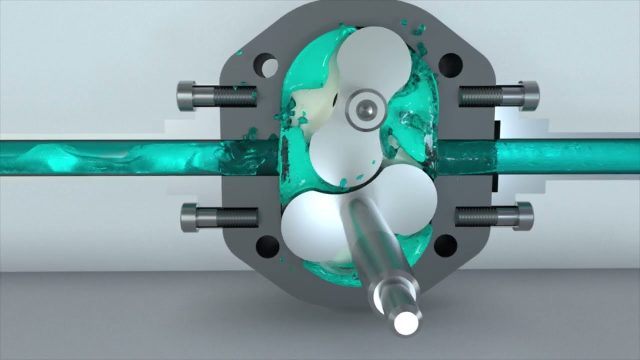

A rotary lobe pump is a type of positive displacement pump that uses two intermeshing lobed rotors to move fluid. As the lobes rotate, they trap fluid in cavities and carry it around the pump casing from the suction side to the discharge side.

Unlike gear pumps, the lobes in a rotary lobe pump never touch—reducing wear and allowing for gentle fluid transfer. This makes them ideal for applications where cleanliness, viscosity, and particle handling are important.

Key Benefits of Rotary Lobe Pumps

-

Hygienic Design: Many models are CIP (Clean-In-Place) and SIP (Steam-In-Place) compatible, making them a top choice for food, beverage, and pharmaceutical processes.

-

Low Shear Handling: Perfect for fragile fluids like cream, gel, or yogurt—preserving texture and quality.

-

Solid Handling: Can pass soft solids such as fruit chunks, curds, or meat bits without damaging them.

-

Reversible Flow: Useful for tank filling and emptying using the same pump.

-

Self-Priming: Can lift fluids from below the pump’s inlet level with ease.

-

Wide Viscosity Range: Performs well with everything from water-like fluids to ultra-thick sludges or pastes.

Common Applications for Rotary Lobe Pumps

These pumps are trusted across industries that demand both precision and durability:

-

Food & Beverage: Jams, sauces, chocolate, syrups, dairy, beer, wine.

-

Pharmaceuticals: Ointments, lotions, active ingredients, and culture suspensions.

-

Cosmetics & Personal Care: Creams, gels, shampoos, body washes.

-

Agriculture: Molasses, nutrient mixes, slurry applications.

-

Chemical Processing: Corrosive or abrasive fluids, slurries, and concentrates.

-

Wastewater Treatment: Sludge, biosolids, and thickened waste streams.

Technical Specifications

When choosing a rotary lobe pump, here are a few essential considerations:

-

Flow Rates: From 10 L/min to over 1,000 L/min depending on size and rotor type.

-

Pressure: Can operate up to 20 bar (290 PSI) in most applications.

-

Viscosity Capability: Up to 1,000,000 cP with specialized rotors.

-

Materials: Pumps are typically constructed from 316 stainless steel, with elastomers tailored to your fluid’s chemical properties (EPDM, Viton, PTFE, etc.).

-

Rotor Styles: Bi-wing, tri-lobe, or multi-lobe—each suited to different applications and viscosities.

-

Sealing Options: Mechanical seals, lip seals, or double mechanical seals depending on the application and compliance requirements.

Maintenance & Longevity

Rotary lobe pumps are built for long life, but good maintenance is key:

-

Inspect lobes and seals regularly for wear or damage.

-

Flush pump after each use in sensitive or hygienic operations.

-

Lubricate bearings and gearbox according to manufacturer specs.

-

Use genuine parts for rebuilds to maintain clearances and certifications.

Why Choose MultiTorque?

At MultiTorque, we don’t just sell pumps—we provide pumping solutions tailored to your industry, budget, and technical needs. We stock and service premium-grade rotary lobe pumps, including options for mobile setups, trailer mounting, or integration into automated systems.

With 15+ years of experience, national reach, and a no-nonsense attitude toward reliability, we help keep your production line or process plant flowing smoothly, day in and day out.

Need a rotary lobe pump that delivers consistent results with zero compromise? Call MultiTorque today on 1300 726 525 or email sales@multitorque.com.

🔗 Visit us online at: https://www.multitorque.com.au

🔗 Connect with us on LinkedIn: https://www.linkedin.com/company/multitorque-industries