PC Pump Parts: Reliability and Efficiency in Industrial Supply 2026

PC Pump Parts

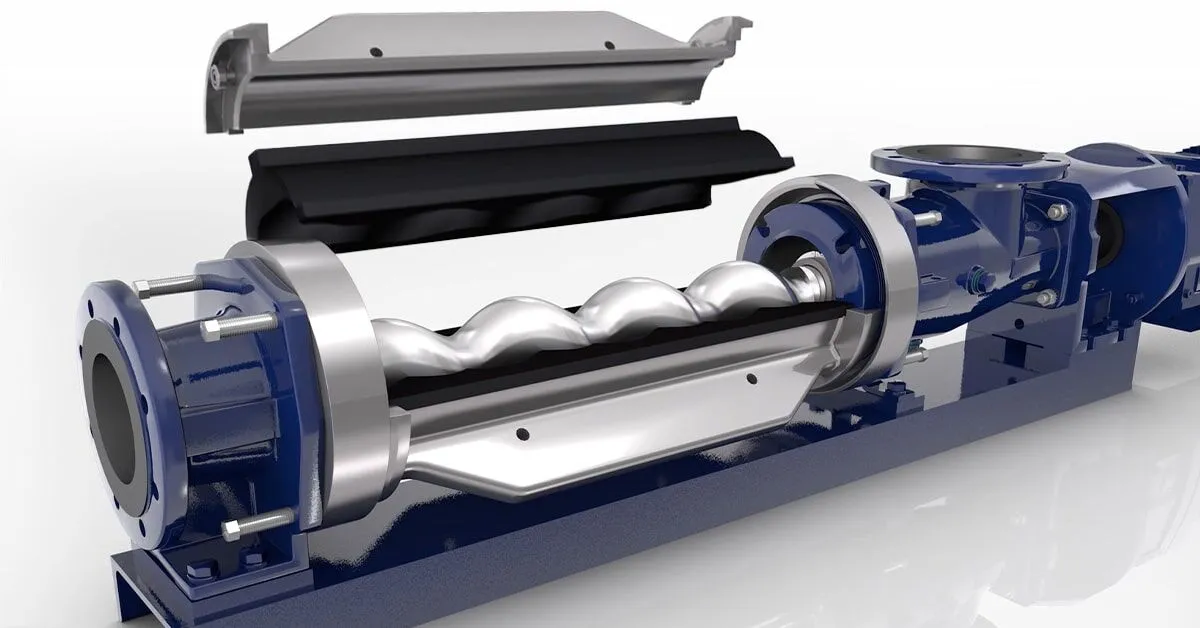

Progressive cavity (PC) pumps are widely used across industries for their ability to handle viscous, abrasive, and shear-sensitive materials with precision and reliability. From wastewater treatment plants to food production facilities, these pumps provide consistent flow rates and low pulsation, making them invaluable for demanding operations. To keep them performing at their best, maintaining and replacing PC pump parts is essential. Understanding how these parts work, their common wear points, and the importance of sourcing quality components can save companies time, money, and downtime.

For expert advice and premium PC pump parts that keep your operations running at peak performance, contact MultiTorque today at 1300 726 525 or email sales@multitorque.com.

What Are PC Pump Parts?

PC pumps rely on a simple yet highly effective design consisting of two key components: the rotor and the stator. The rotor is typically a helical metallic shaft, while the stator is an elastomer-lined component that houses the rotor. As the rotor turns inside the stator, cavities are formed that move fluid steadily from the suction end to the discharge end.

In addition to rotors and stators, other essential PC pump parts include:

- Drive shafts – transmit torque from the motor to the rotor.

- Couplings – connect the rotor and drive shaft while accommodating movement.

- Seals – prevent leakage and maintain efficiency.

- Bearings and universal joints – reduce wear and ensure smooth operation.

- Pump housing and liners – provide durability against abrasive fluids.

Because of the demanding environments PC pumps operate in, each part must be engineered to withstand mechanical stress, chemical exposure, and high pressures.

Why PC Pump Parts Matter

Every pump operator knows that downtime can cost thousands of dollars per hour. When PC pump parts begin to wear, efficiency drops, energy consumption rises, and the risk of unexpected failure increases. Regularly inspecting and replacing worn parts is critical to ensuring uninterrupted operation.

High-quality replacement parts help maintain:

- Consistent flow rates – even with highly viscous or abrasive media.

- Energy efficiency – reducing operating costs.

- Longevity of equipment – extending the pump’s service life.

- Safety – preventing leaks, pressure surges, and operational hazards.

By choosing the right PC pump parts, businesses can prevent costly breakdowns while maximising productivity.

Common Signs That PC Pump Parts Need Replacement

Operators should monitor for the following indicators that PC pump parts are due for maintenance or replacement:

- Decreased pumping efficiency – lower output despite normal operating conditions.

- Excessive vibration or noise – often a sign of worn couplings or bearings.

- Leakage around seals – indicating seal wear or improper installation.

- Irregular flow or pressure surges – caused by rotor or stator wear.

- Increased power consumption – suggesting the pump is working harder than necessary.

Addressing these issues early by replacing the right components can prevent complete pump failure.

Types of PC Pump Parts Available

There are several categories of PC pump parts designed for different applications and industries:

- Standard-duty parts – for general pumping needs such as water or light slurries.

- Abrasion-resistant parts – for handling mining slurries, cement, and abrasive chemicals.

- Food-grade parts – manufactured with stainless steel and FDA-approved elastomers.

- Chemical-resistant parts – made to withstand corrosive fluids such as acids and solvents.

Selecting the right type of parts ensures optimal compatibility with the pumped media and extends pump performance.

The Role of Reputable Brands in PC Pump Parts

Not all PC pump parts are created equal. Leading global brands have set the benchmark for quality, innovation, and durability in the progressive cavity pump industry. For example:

- NETZSCH Progressive Cavity Pumps are known for their advanced engineering and ability to handle challenging fluids. Their parts are built for long-term reliability, particularly in industrial and chemical applications.

- SEEPEX Pumps offer modular designs that make replacing PC pump parts more efficient. Their elastomers and stators are designed for consistent performance and ease of maintenance.

- Mono Progressive Cavity Pumps are widely used in wastewater and industrial processes. Their spare parts are trusted for durability and compatibility, reducing downtime in critical systems.

- NOV Mono Pumps are another respected brand in the PC pump market, offering reliable pump parts that meet the needs of mining, oil, and gas sectors.

By sourcing PC pump parts from these reputable brands, operators ensure they are investing in proven quality and performance.

OEM vs Aftermarket PC Pump Parts

When replacing PC pump parts, operators often face a choice between OEM (original equipment manufacturer) and aftermarket parts.

- OEM Parts – Designed by the original manufacturer, guaranteeing precise fit and compatibility. They are generally more expensive but offer peace of mind.

- Aftermarket Parts – Produced by third-party manufacturers, often at a lower cost. Quality can vary, so it’s crucial to source them from trusted suppliers with proven track records.

In many cases, high-quality aftermarket PC pump parts can match or even exceed OEM standards while providing cost savings.

Benefits of Regular Maintenance with PC Pump Parts

Integrating a proactive maintenance strategy with regular replacement of PC pump parts offers several advantages:

- Reduced downtime – scheduled maintenance avoids unexpected breakdowns.

- Improved efficiency – fresh parts restore pump performance.

- Lower long-term costs – prevents major repairs or complete pump replacements.

- Extended equipment life – maximises return on investment for pumping systems.

A structured maintenance schedule, combined with reliable spare parts, keeps PC pumps running smoothly even under harsh conditions.

Industries That Depend on PC Pump Parts

Progressive cavity pumps and their parts are critical across multiple sectors, including:

- Mining – for handling abrasive slurries and tailings.

- Wastewater treatment – for sludge, biosolids, and chemical dosing.

- Food and beverage – for transferring syrups, dairy products, and sauces.

- Oil and gas – for crude oil and drilling mud.

- Agriculture – for irrigation and fertiliser handling.

Each industry requires specific PC pump parts tailored to its unique fluid characteristics and operating environments.

Why Choose MultiTorque for PC Pump Parts

As a trusted Australian supplier, MultiTorque specialises in sourcing and supplying PC pump parts from the world’s leading brands. With a commitment to reliability, safety, and customer satisfaction, MultiTorque ensures every client receives the right parts for their specific pumping requirements.

For expert advice and premium PC pump parts that keep your operations running at peak performance, contact MultiTorque today at 1300 726 525 or email sales@multitorque.com.

By offering access to genuine and high-quality aftermarket PC pump parts, MultiTorque supports industries nationwide in minimising downtime, improving efficiency, and protecting long-term investments in pump systems.

Final Thoughts

PC pumps are the backbone of many industrial processes, and their performance depends heavily on the quality and condition of their components. Regular inspection, timely replacement, and sourcing from trusted suppliers are key to maintaining efficiency and reliability.

Whether it’s rotors, stators, seals, or complete assemblies, choosing the right PC pump parts keeps operations running smoothly while reducing overall costs. By working with proven brands such as NETZSCH, SEEPEX, Mono, and NOV Mono—and with the expertise of suppliers like MultiTorque—industries can ensure they have the pumping power needed to thrive in even the most challenging conditions.