Mono Helical Rotor Pump: Supply & Repair From MultiTorque 2025

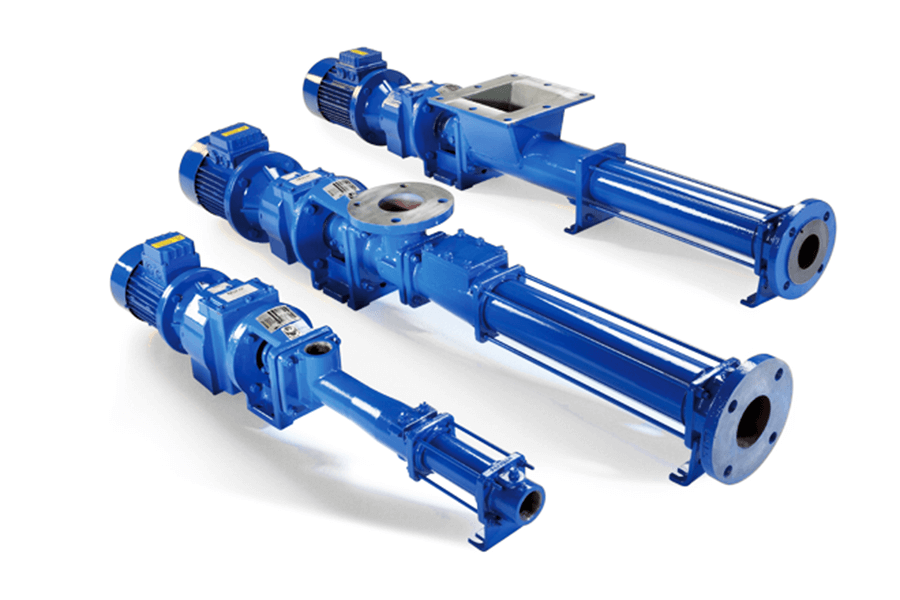

In industries where reliability, precision, and efficiency are critical, the Mono Helical Rotor Pump stands out as a proven solution. Known for its ability to handle challenging fluids while maintaining consistent flow, this type of pump has become an industry standard across sectors such as mining, wastewater treatment, food processing, and oil and gas. At MultiTorque, we specialize in supplying, servicing, and repairing Mono Helical Rotor Pumps to ensure your operations run smoothly.

📞 Call us today on 1300 726 525 or email sales@multitorque.com to discuss your pumping needs.

What is a Mono Helical Rotor Pump?

A Mono Helical Rotor Pump—often referred to as a progressive cavity pump—uses a helical rotor and a stator to move fluids through a sequence of cavities. Unlike centrifugal pumps, which rely on high-speed impellers, this pump design provides steady, low-pulsation flow even with highly viscous or abrasive fluids.

The pump consists of two main components:

- Helical Rotor – A precision-engineered screw-shaped component that rotates inside the stator.

- Stator – A molded component that creates tight cavities with the rotor to trap and move fluid.

This design allows the Mono Helical Rotor Pump to deliver:

- Gentle pumping action

- Accurate, consistent flow rates

- The ability to handle solids, slurries, and shear-sensitive fluids

Why Choose a Mono Helical Rotor Pump?

Choosing the right pump for your application is crucial. The Mono Helical Rotor Pump offers multiple advantages that make it suitable for tough industrial environments.

1. Versatility in Applications

From dewatering mines to pumping sludge in wastewater plants, the helical rotor design can manage liquids of varying viscosities and compositions. This versatility reduces downtime and provides long-term reliability.

2. Consistent Flow and Pressure

Unlike other pumps that create pressure fluctuations, Mono Helical Rotor Pumps provide a smooth, non-pulsating flow. This makes them ideal for dosing, chemical injection, and precise fluid transfer.

3. Ability to Handle Abrasive and Viscous Media

Industries like mining and oil & gas often deal with thick, abrasive slurries. The Mono Helical Rotor Pump is built to handle these fluids without clogging or excessive wear.

4. Energy Efficiency

By maintaining a consistent flow at lower speeds, these pumps consume less energy, resulting in reduced operational costs.

Applications of Mono Helical Rotor Pumps

The Mono Helical Rotor Pump is used across multiple industries where durability and reliability are essential:

- Mining – Ideal for transferring tailings, thick slurries, and dewatering applications.

- Wastewater Treatment – Used for pumping sludge, polymers, and sewage without blockages.

- Food & Beverage – Perfect for handling shear-sensitive materials like sauces, purees, and dairy products.

- Oil & Gas – Reliable for crude oil transfer and other viscous hydrocarbons.

- Agriculture – Useful for irrigation, effluent transfer, and slurry pumping.

MultiTorque: Experts in Mono Helical Rotor Pumps

At MultiTorque, we don’t just supply pumps—we deliver full lifecycle support. With over 15 years of experience in the pump industry, our team ensures your Mono Helical Rotor Pump performs at its best.

Our Services Include:

- Supply of Mono Helical Rotor Pumps – We source high-quality pumps tailored to your specific needs.

- Workshop Repairs – Our skilled technicians handle complete in-house rebuilds and servicing.

- Spare Parts Supply – From stators to rotors, we provide genuine and compatible pump components.

- Custom Solutions – We design pump systems, including trailers and skids, for demanding field applications.

Whether you need a new Mono Helical Rotor Pump or require professional servicing, MultiTorque ensures you get maximum performance and reliability.

Related Pump Solutions

MultiTorque supplies and services a wide range of pumps, ensuring that clients can find the best fit for their specific applications. Some of our related pump solutions include:

- Explore our article on the Mono MS Pump for details on another efficient progressive cavity pump option.

- Learn more about the Mono X Pump for durable performance in heavy-duty applications.

- Discover the reliability of the Allweiler Screw Pump, widely used in industrial and marine environments.

- See how the Electric Diaphragm Water Pump provides flexible solutions for mobile and remote pumping needs.

- Review our guide on the Ingersoll Rand Diaphragm Pump Rebuild Kit to extend pump life with proper maintenance.

These resources help you compare pump types and identify the most suitable option for your operational requirements.

Why Work with MultiTorque?

Choosing MultiTorque as your pump partner comes with clear advantages:

- Australian Expertise – With locations in Perth and Brisbane, we provide national coverage.

- Industry Experience – More than 15 years supporting clients in mining, oil & gas, water treatment, and manufacturing.

- Customer-Centric Approach – We focus on building long-term relationships with our clients.

- In-House Repairs Only – To ensure quality control, we perform all pump repairs in our own workshops.

- Commitment to Safety & Reliability – Every service we deliver aligns with industry safety standards and operational efficiency.

Call MultiTorque Today

If your business relies on dependable pump systems, the Mono Helical Rotor Pump is an excellent choice. At MultiTorque, we provide top-quality supply, repair, and servicing solutions to keep your operations running efficiently.

📞 Call us today on 1300 726 525 or email sales@multitorque.com to discuss your pumping needs.

🌐 Learn more at www.multitorque.com.au.

🔗 Connect with us on LinkedIn for the latest updates and industry insights.