Gear Pump Displacement Explained: Powerful Solutions from MultiTorque 2025

Gear pumps are a cornerstone of industrial fluid handling, offering reliable performance in applications that require consistent flow, pressure, and durability. Understanding gear pump displacement is essential for selecting the right pump for your operation. At MultiTorque, we supply, service, and rebuild high-quality gear pumps designed to meet the demands of industries across Australia, from manufacturing and mining to chemical processing and agriculture.

With over 15 years of experience, MultiTorque has earned a reputation as a trusted supplier and service provider for industrial pump solutions.

📞 Phone: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: www.multitorque.com.au

🔗 LinkedIn: MultiTorque Industries

What is Gear Pump Displacement?

Gear pump displacement refers to the volume of fluid a gear pump can move per revolution. It is typically measured in liters per minute (L/min) or gallons per minute (GPM) and is influenced by the pump’s internal design, including the size and number of gears, the diameter of the gear teeth, and the pump housing.

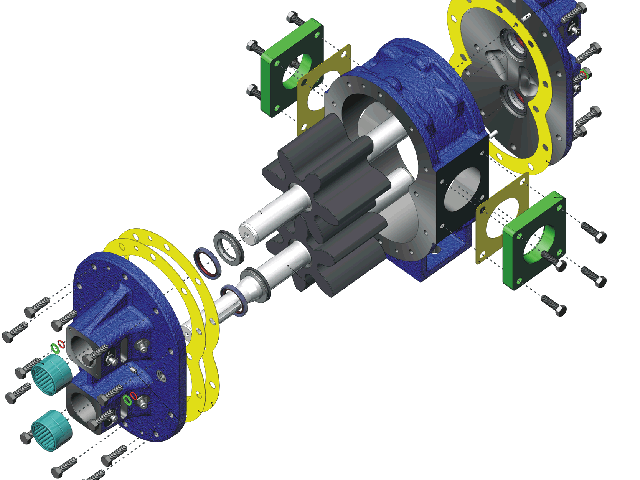

There are two main types of gear pumps:

- External Gear Pumps: These have two meshing gears that rotate in opposite directions, creating suction at the inlet and pushing fluid through the outlet.

- Internal Gear Pumps: These have a larger internal gear and a smaller external gear, with fluid trapped between the gears and moved through the pump.

Understanding the displacement helps businesses calculate the flow rate, pressure, and suitability of the pump for their specific application.

Why Gear Pump Displacement Matters

Choosing a pump with the correct displacement ensures:

- Accurate Flow Control: Critical in chemical dosing, lubrication, and hydraulic systems.

- Efficient Operation: Prevents under- or over-pumping, saving energy and reducing wear.

- System Compatibility: Ensures the pump matches the operational requirements of motors, valves, and other equipment.

- Cost-Effectiveness: Reduces maintenance costs by avoiding excessive wear caused by mismatched flow rates.

At MultiTorque, we guide clients to select the right gear pump based on displacement requirements, fluid properties, and operating conditions.

Applications of Gear Pumps

Gear pumps, including those with precise displacement capabilities, are used in diverse industries:

- Industrial Manufacturing: Circulating lubricants, hydraulic fluids, and coolants.

- Chemical Processing: Handling viscous or corrosive fluids safely.

- Food & Beverage: Moving syrups, oils, and other thick liquids without compromising product integrity.

- Mining and Agriculture: Dewatering, chemical dosing, and fluid transfer.

- Oil & Gas: Fuel transfer and chemical injection systems (read more about Cat pump oil).

Proper pump displacement is key to maintaining consistent flow and avoiding operational disruptions.

Factors Affecting Gear Pump Displacement

Several factors influence the displacement of a gear pump:

- Gear Size and Type: Larger gears displace more fluid per revolution, while the gear type (external vs. internal) affects flow characteristics.

- Clearances: Tight tolerances between gears and the housing reduce leakage and improve efficiency.

- Viscosity of Fluid: Highly viscous fluids may require adjustments to pump speed or gear size.

- Operating Speed: Pump speed directly affects the volume delivered per unit of time.

- Temperature and Pressure: High temperatures or pressures can impact displacement performance if the pump isn’t designed for these conditions.

MultiTorque helps clients select pumps that maintain optimal displacement under their specific operating conditions.

MultiTorque Gear Pump Solutions

At MultiTorque, we supply and service a broad range of gear pumps with reliable displacement performance. Our offerings include:

- External and Internal Gear Pumps: Suitable for diverse industrial applications.

- Custom Pump Solutions: Tailored to meet specific displacement, flow, or chemical handling requirements.

- Pump Parts and Accessories: Gears, seals, and bearings to maintain peak performance.

- Pump Skids and Systems: Integrated solutions for efficient fluid handling (see industrial pump skid solutions).

We also provide expert guidance for selecting, operating, and maintaining gear pumps, ensuring longevity and efficiency.

Servicing and Rebuilding Gear Pumps

Even high-quality gear pumps require maintenance to sustain performance. MultiTorque offers comprehensive in-house servicing and rebuilds, including:

- Replacement of worn gears, seals, and bearings

- Cleaning and reconditioning of pump housings

- Testing and performance verification

- Technical advice for system optimization

By relying on MultiTorque, businesses extend the life of their gear pumps and minimize costly downtime.

Industries That Trust MultiTorque

MultiTorque supports a wide range of industries with gear pump expertise:

- Mining and Resources: Reliable pumps for high-volume fluid transfer

- Chemical Processing: Safe handling of aggressive chemicals

- Food & Beverage: Hygienic pump systems for viscous liquids

- Oil & Gas: Efficient fuel and chemical transfer solutions (read about oil and gas pump solutions)

- Manufacturing and Agriculture: Pump systems tailored for operational efficiency

Our solutions are engineered to handle tough conditions while delivering precise flow rates and reliable performance.

Why Choose MultiTorque?

- Experience: Over 15 years supplying, servicing, and rebuilding industrial pumps

- Expertise: Knowledge across gear pumps, progressive cavity pumps, and centrifugal systems

- Custom Solutions: Tailored skid systems and pump configurations

- National Support: Perth and Brisbane branches with in-house workshops

- Customer Commitment: Reliability, safety, and long-term partnership focus

When it comes to gear pump displacement and fluid handling, MultiTorque delivers products and support that meet the most demanding industry standards.

Contact MultiTorque

For high-quality gear pumps with reliable displacement and industry-leading service, contact MultiTorque today:

📞 Phone: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: www.multitorque.com.au

🔗 LinkedIn: MultiTorque Industries