Powerful Auger Fabrication in Australia – Custom Built for Tough Jobs 2025

Custom Auger Fabrication Services That Deliver Performance and Power

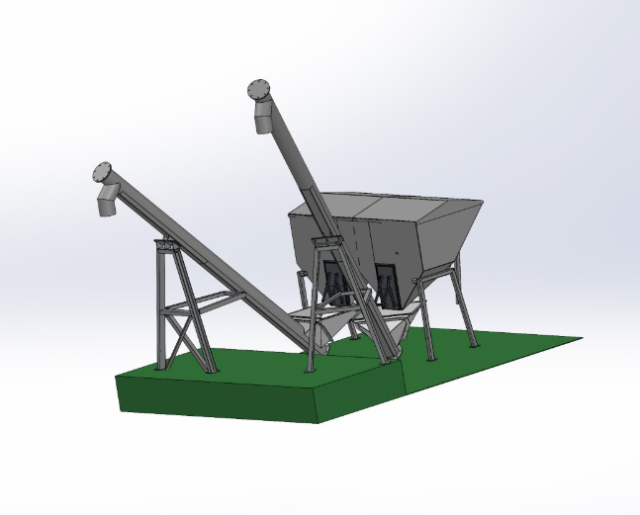

When your operation demands efficient material handling and reliable equipment, a one-size-fits-all solution simply won’t cut it. At MultiTorque, we specialize in custom auger fabrication designed to thrive in the harshest environments—whether you’re shifting grain, drilling soil, or moving sludge on a mine site.

With over 15 years of industrial fabrication experience, we build augers for Australian conditions—tough, precise, and made to perform. Our team works with you to design and manufacture augers and screw conveyors tailored for maximum productivity.

What Is Auger Fabrication?

Auger fabrication involves the design and construction of helical screw mechanisms used to move, drill, or mix materials. Also known as screw conveyors or drill augers, these systems are vital in agriculture, mining, wastewater treatment, and construction.

Our auger fabrication process includes:

-

Custom flighting design

-

Precision shaft construction

-

Mounting and housing fabrication

-

Abrasion-resistant hardfacing

-

Material-specific builds (carbon steel, stainless, or high-alloy)

Whether it’s a horizontal feed auger or a vertical mixing unit, we build systems that match your materials, capacity, and installation space.

Applications of Custom Fabricated Augers

MultiTorque supplies fabricated augers for a wide range of industrial uses:

-

Mining & Quarrying – Tailings transport, sand conveyance, and ore handling

-

Agriculture – Grain loading augers, feed screws, and seed drills

-

Wastewater & Utilities – Sludge movement, biosolids processing

-

Construction – Soil drilling, foundation screw piles

-

Food & Beverage – Powder, pellet, and ingredient mixing or conveying

-

Manufacturing – Bulk materials transfer, plastic resins, and recycling

We also fabricate augers for borehole support systems under our BoreBoss division, integrating them into mobile units for remote and on-site use.

Why Choose Custom Auger Fabrication?

Standard augers don’t always suit real-world conditions. That’s why a tailored solution is essential for performance, safety, and durability. At MultiTorque, we consider every detail:

-

Material flow properties (wet, dry, abrasive, sticky)

-

Desired output rate

-

Wear-resistance and cleaning access

-

Power compatibility and space limitations

-

Site-specific design constraints

Our augers are made to measure, meaning less downtime, more output, and zero compromise.

Built to Last: Our Auger Fabrication Capabilities

✅ Up to 6m single-shaft augers (longer units available with split couplings)

✅ Fully welded or sectional flighting options

✅ Hardfacing and ceramic coating for high-wear jobs

✅ Custom hoppers, chutes, and housing enclosures

✅ Drive integration (electric, hydraulic, or PTO-powered)

✅ Skid-mounted, trailer-mounted, or frame-mounted options

Our in-house team handles CAD design, material selection, welding, fitting, and pressure testing. You get complete quality control and local accountability with every job.

Trusted Across Australia’s Harshest Sites

MultiTorque is proud to fabricate augers and industrial pumping solutions for some of Australia’s biggest names in mining, agriculture, and infrastructure. We work directly with site managers, engineers, and procurement teams to ensure the final product is fit for purpose, easy to maintain, and built to endure.

From Perth to Brisbane and everywhere in between, we support industries that move mountains—literally.

Start Your Fabrication Project with MultiTorque Today

When off-the-shelf doesn’t cut it, trust MultiTorque to build a solution that does. Our custom auger fabrication is fast, reliable, and backed by years of experience working with Australian industry. Let’s build an auger system that makes your operation more efficient and your life easier.

📞 Call us now on 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: www.multitorque.com.au