Dewatering is a critical process in construction, mining, civil works, and industrial projects. Removing excess water from sites ensures safety, efficiency, and uninterrupted operations. When it comes to sourcing equipment for these tasks, choosing the right dewatering pump manufacturers is essential. MultiTorque has over 15 years of experience supplying, servicing, and repairing high-performance dewatering pumps designed to meet the rigorous demands of Australian industries.

📞 Call 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

🔗 Connect: MultiTorque LinkedIn

In this article, we’ll explore the importance of dewatering pumps, what makes a reliable pump manufacturer, and how MultiTorque can provide end-to-end solutions for your project.

What Are Dewatering Pumps?

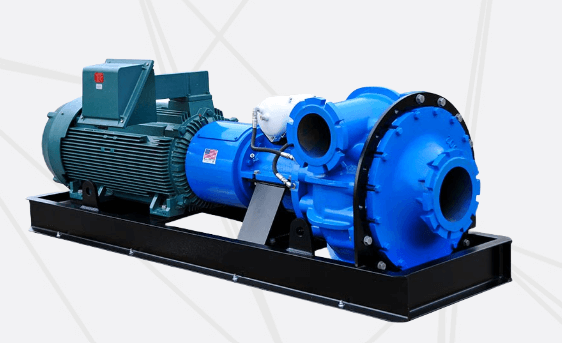

Dewatering pumps are specialized pumps designed to remove groundwater, surface water, or accumulated liquids from construction sites, mines, tunnels, or industrial environments. They are robust, high-capacity pumps capable of handling large volumes of water, including debris-laden or sediment-heavy fluids.

These pumps are essential for maintaining safe working conditions, preventing flooding, and protecting equipment and infrastructure. They are used in applications such as:

- Construction site excavation and trench dewatering

- Mining pit and tunnel dewatering

- Industrial flood control

- Stormwater management

- Civil engineering projects

Key Features of Dewatering Pumps

Reliable dewatering pumps, provided by top dewatering pump manufacturers, share several key characteristics:

- High Flow Rates – Dewatering pumps must move large volumes of water quickly to prevent delays or flooding.

- Durability – Constructed with heavy-duty materials such as cast iron or stainless steel, these pumps can withstand abrasive particles and continuous operation.

- Solids Handling – Many dewatering pumps are capable of passing debris, sand, and silt without clogging.

- Portable Options – Mobile pumps with trailer-mounted or skid-mounted designs allow easy deployment across sites.

- Energy Efficiency – Designed to operate at optimal efficiency, reducing operational costs.

By choosing pumps with these features, contractors and industrial operators can ensure smooth, uninterrupted operations even in challenging conditions.

Types of Dewatering Pumps

Depending on the application, different types of dewatering pumps may be required. Common options include:

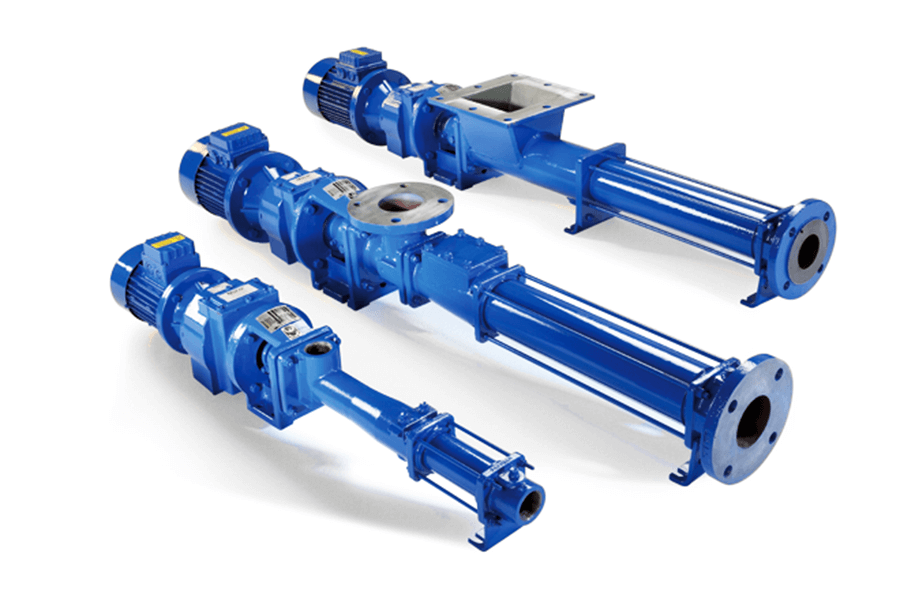

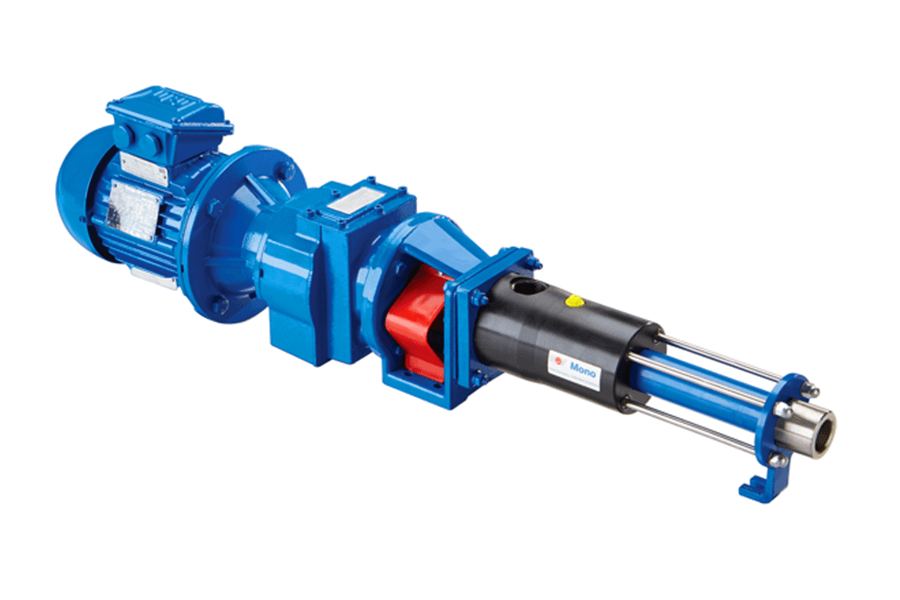

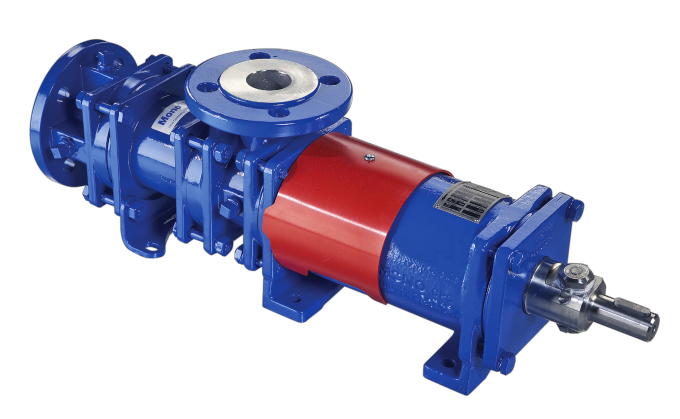

1. Centrifugal Dewatering Pumps

Centrifugal pumps are widely used for dewatering because of their ability to handle high flow rates. They use rotational energy to move water and are suitable for applications with low to medium solid content.

2. Submersible Dewatering Pumps

These pumps operate underwater and are ideal for removing water from deep excavations or flooded areas. Submersible pumps are compact, quiet, and efficient.

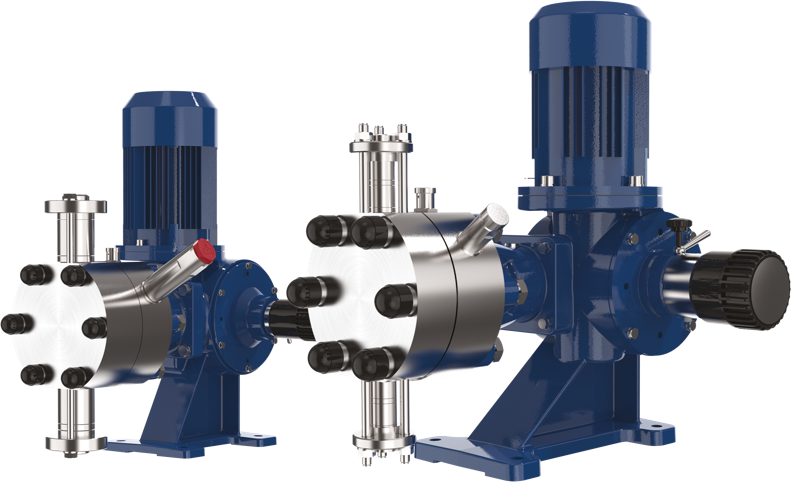

3. Diaphragm Dewatering Pumps

Diaphragm pumps can handle highly abrasive and viscous fluids. They are commonly used in mining and industrial applications where sediment-laden water needs to be moved safely.

4. Self-Priming Dewatering Pumps

Self-priming pumps can evacuate air and start pumping without manual priming, making them ideal for temporary worksites where quick deployment is necessary.

5. Trailer-Mounted Dewatering Units

For large-scale projects, trailer-mounted pumps provide mobility and flexibility. MultiTorque designs custom dewatering pump trailers that allow easy transportation between sites.

Why Choosing the Right Dewatering Pump Manufacturer Matters

The choice of dewatering pump manufacturers directly impacts efficiency, reliability, and long-term maintenance costs. High-quality manufacturers deliver:

- Durable, robust pumps built for harsh operating conditions

- Reliable spare parts and servicing support to reduce downtime

- Technical expertise to recommend the right pump type for specific applications

- Custom solutions for unique site requirements

Selecting a reputable manufacturer ensures that your dewatering operations run smoothly, even in demanding environments.

MultiTorque: Trusted Dewatering Pump Manufacturer and Supplier

MultiTorque is a leading provider of dewatering pumps in Australia, offering supply, service, and custom solutions for a wide range of industries. Here’s why MultiTorque is the preferred choice for businesses across Perth, Brisbane, and nationwide:

1. Industry Expertise

With over 15 years of experience, MultiTorque understands the needs of mining, construction, and industrial operators. We provide technical advice to ensure the right pump is selected for your specific requirements.

2. In-House Servicing and Repairs

All pump repairs are conducted in our workshops, guaranteeing high-quality workmanship. From minor maintenance to full overhauls, our technicians keep your equipment performing reliably.

3. Custom Pump Solutions

Some projects require specialized setups. MultiTorque offers custom dewatering trailers and pump configurations, enabling operators to manage unique site challenges efficiently.

4. Access to Genuine Parts

We stock and source high-quality spare parts to keep pumps running at peak performance. From impellers to seals and hoses, our parts inventory reduces downtime.

5. Nationwide Support

With branches in Perth and Brisbane, MultiTorque can supply, install, and service pumps across Australia, ensuring rapid response to urgent needs.

Applications of MultiTorque Dewatering Pumps

Dewatering pumps supplied by MultiTorque are used in a variety of applications, including:

- Construction Sites – Excavation, trenching, and foundation dewatering

- Mining Operations – Moving water from pits, tailings dams, or tunnels

- Industrial Facilities – Flood prevention and water management

- Municipal Projects – Stormwater and sewer management

- Emergency Response – Rapid water removal during floods or high rainfall events

These pumps are designed to withstand challenging conditions while providing efficient water removal, protecting both people and infrastructure.

Benefits of Choosing MultiTorque for Dewatering Pumps

When selecting a dewatering pump supplier and manufacturer, MultiTorque offers several advantages:

- Reliability: Durable pumps built for extreme conditions

- Efficiency: High-performance designs that save energy

- Support: Technical advice, service, and repair options

- Custom Solutions: Tailored to your project’s unique needs

- Experience: Over 15 years serving Australian industries

By partnering with MultiTorque, you’re ensuring your dewatering operations are managed efficiently, safely, and reliably.

Conclusion

Dewatering pumps are essential for safe and effective operations across mining, construction, industrial, and municipal sites. Choosing the right dewatering pump manufacturer ensures high performance, minimal downtime, and long-term cost savings. MultiTorque combines expert knowledge, high-quality pumps, in-house servicing, and custom solutions to provide reliable dewatering systems tailored to the Australian environment.

For trusted dewatering pump supply and servicing, contact MultiTorque today.

📞 Call 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

🔗 Connect: MultiTorque LinkedIn