Precision, Reliability, and Speed: Your Auger Filler Machine Manufacturer

When accurate dosing and efficient packaging matter, industries turn to the experts. As a premier auger filler machine manufacturer, MultiTorque delivers robust, high-performance filling systems tailored for powders, granules, and fine particulate materials.

From dry food mixes to industrial-grade chemicals, our auger filler machines are engineered for speed, accuracy, and long-term reliability. Whether you run a fast-paced packaging line or a custom formulation lab, we provide the tools to streamline your process and reduce waste.

What Is an Auger Filler Machine?

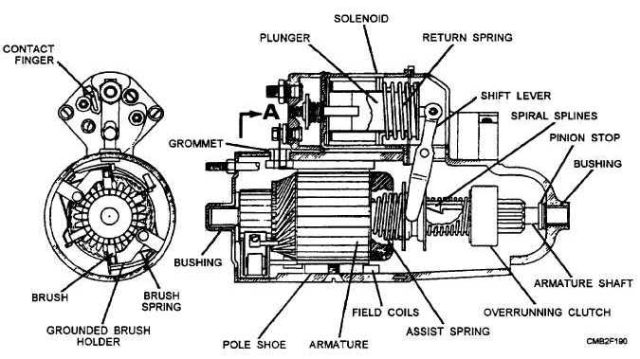

An auger filler machine is a type of volumetric filling system used to dispense dry products with precision. It uses a rotating auger screw to push product through a funnel into containers like jars, bags, or bottles.

These systems are ideal for:

-

Powdered Foods (flour, spices, milk powder)

-

Pharmaceutical Powders & Supplements

-

Chemicals & Additives

-

Detergents, Fertilizers, and Agricultural Blends

-

Plastic Pellets or Granules

At MultiTorque, our auger filler machines are built using stainless steel and food-safe components, designed to meet HACCP and GMP compliance standards where required.

Why Choose MultiTorque as Your Auger Filler Machine Manufacturer?

✔ Precision Filling from 1g to 50kg+

✔ Custom-Built Systems Tailored to Your Line

✔ Single-Station or Integrated Inline Units

✔ High-Speed and Semi-Automatic Options Available

✔ Trusted by Food, Pharma, and Industrial Operators Nationwide

As a locally owned Australian manufacturer with 15+ years of industrial fabrication experience, we don’t do off-the-shelf. We design, engineer, and fabricate filler systems that fit your exact specs and production goals.

Machine Types We Offer

🔧 Tabletop Auger Fillers – Compact and semi-automatic units ideal for laboratories, startups, and test lines.

🔧 Automatic Inline Fillers – High-speed rotary or conveyor-fed fillers for medium-to-large packaging operations.

🔧 Vertical Form Fill Seal (VFFS) Integration – Designed to work seamlessly with VFFS bagging machines for powders.

🔧 Servo-Driven Fillers – Highly accurate dosing with programmable fill cycles for sensitive products.

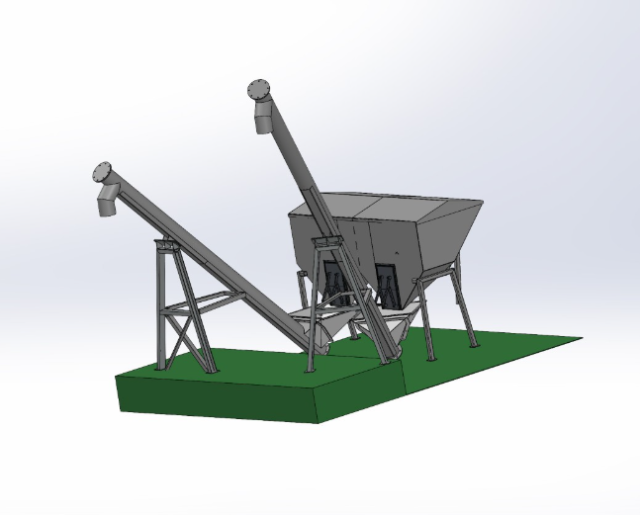

🔧 Custom Hopper Sizes & Screw Designs – From fine powders to free-flowing granules, we customize every component.

Industries We Serve

MultiTorque auger filler machines are trusted in:

-

Mining Emulsion Augers

-

Blasting

-

Agricultural Blends & Feed Processing

-

Chemical & Fertilizer Manufacturing

-

Cleaning Products & Powders

-

Pet Food & Additive Dispensers

If it flows like powder or pellets, we can fill it—quickly, accurately, and cleanly.

Built for Compliance & Cleanability

Our filler systems are manufactured using 304 or 316 stainless steel, with sanitary welds and easy-access clean-down features. We meet and exceed food safety standards, including:

-

HACCP

-

GMP (Good Manufacturing Practices)

-

FDA-Compatible Materials (on request)

Whether you need an industrial-grade stainless auger or a delicate lab-scale filler, we’ve got the tooling, automation, and service to deliver.

After-Sales Support That Keeps You Running

What makes MultiTorque the best auger filler machine manufacturer isn’t just the machines—it’s the support behind them. We offer:

-

Spare parts & auger replacement screws

-

Calibration & service checks

-

Integration help with other machinery

-

Local repairs and fast lead times

We’re not just your supplier—we’re your long-term partner in precision packaging.

Let’s Build Your Perfect Filler Machine

Your production deserves more than guesswork. Choose an auger filler machine manufacturer that gets it right the first time—MultiTorque.

📞 Call us now at 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

MultiTorque: Engineering Precision Since Day One

From food to pharma to fertilizer, our auger filler machines are built with Aussie engineering, custom craftsmanship, and a fierce commitment to quality. If your business depends on accurate, clean, and consistent filling—MultiTorque is the name to remember.

In heavy industries where performance and reliability matter most, having the right pump setup isn’t a luxury—it’s a necessity. That’s where MultiTorque comes in. With over 15 years of hands-on industry experience, we’re Australia’s trusted name in pump fabrication, delivering custom-built pump solutions to mines, farms, processing plants, and infrastructure projects nationwide.

In heavy industries where performance and reliability matter most, having the right pump setup isn’t a luxury—it’s a necessity. That’s where MultiTorque comes in. With over 15 years of hands-on industry experience, we’re Australia’s trusted name in pump fabrication, delivering custom-built pump solutions to mines, farms, processing plants, and infrastructure projects nationwide.

When it comes to industrial operations, having a dependable, well-designed pump skid system can be the difference between smooth operations and costly downtime. At MultiTorque, we specialise in pump skid fabrication built specifically for Australia’s toughest environments—from mining and oil to agriculture, dewatering, and processing.

When it comes to industrial operations, having a dependable, well-designed pump skid system can be the difference between smooth operations and costly downtime. At MultiTorque, we specialise in pump skid fabrication built specifically for Australia’s toughest environments—from mining and oil to agriculture, dewatering, and processing.