If you’re running a progressive cavity pump, then the mono pump rotor is the heart of your operation. This critical component delivers the smooth, low-pulse flow that makes progressive cavity pumps ideal for everything from wastewater to food-grade slurries.

At MultiTorque, we supply high-quality mono pump rotors and related parts across Australia. Whether you’re replacing worn internals or upgrading your entire system, we’ve got the right parts on hand—and ready to ship.

What Is a Mono Pump Rotor?

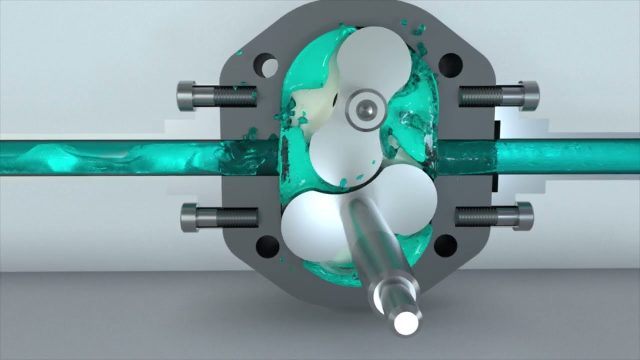

A mono pump rotor is a helical metal component that works together with a rubber stator to create sealed cavities that push fluid forward. It’s the rotating element of a progressive cavity (PC) pump, often used in sludge handling, oil transfer, and chemical dosing.

The rotor typically features a precision-machined, hardened metal design—either chrome-plated or stainless steel—matched to a soft elastomer stator. The tight fit between rotor and stator ensures consistent pressure and flow, even with abrasive or high-viscosity fluids.

Why Is the Rotor So Important?

Without a high-quality rotor, your mono pump will underperform or fail prematurely. Here’s what a top-notch rotor brings to your operation:

✅ Accurate Flow Rates

Rotors form progressive cavities that maintain constant flow—ideal for metering and dosing.

✅ Handles Viscous & Abrasive Fluids

Sludges, pastes, and even fine slurries are no match for a correctly specced rotor.

✅ Long Wear Life

Hardened metals and proper coatings reduce wear from abrasives and harsh chemicals.

✅ Easy Replacement

Rotors are designed for straightforward removal and reinstallation during service.

✅ Versatility

Works across multiple industries: wastewater, mining, oil & gas, agriculture, food processing, and more.

Signs You Need a New Mono Pump Rotor

Even the toughest rotors wear out. Here’s how you know it’s time to replace yours:

-

🔻 Loss of flow or pressure

-

🔊 Unusual vibration or noise

-

⚠️ Excessive leakage or weeping

-

🔩 Rotor visibly pitted or worn

-

🔁 Increased drive load or motor amps

If your rotor is scored, cracked, or losing tolerance with the stator, it’s time for a new one.

We Supply Mono Pump Rotors and More

At MultiTorque, we don’t just service pumps—we supply top-tier replacement parts to keep your plant moving.

We carry rotors compatible with:

-

Mono® brand pumps

-

NOV and other PC pump brands

-

Stainless steel and chrome options

-

Standard pitch and extended pitch configurations

-

Rotors for food-grade, chemical, or abrasive fluid applications

Need help identifying your pump model? We’ll match the part or reverse-engineer a solution.

Industries That Rely on Our Rotors

We supply mono pump parts to companies across:

-

🛢️ Oil & Gas – Oil transfer, drill site dosing

-

🏭 Industrial & Chemical – Caustics, solvents, sludge

-

💧 Wastewater Treatment – Sludge thickening, dewatering

-

🌱 Agriculture – Fertiliser and effluent pumping

-

🍅 Food & Beverage – Syrups, mash, and pulp transfer

-

⛏️ Mining – Paste, slurry, and thickened tailings

Need a rotor now? We’ve got stock in Perth and Brisbane for fast national delivery.

Why Buy From MultiTorque?

We’re more than just a parts supplier. We’ve been supporting Australian industry for over 15 years, delivering:

-

✅ Fast access to rotors, stators, seals, and pump internals

-

✅ Field service and installation support

-

✅ Repairs, rebuilds, and full pump overhauls

-

✅ Custom trailer builds for dewatering and dosing

-

✅ Genuine and aftermarket parts to match any budget

Whether you’re after a single rotor or a full progressive cavity pump system—we’re your one-stop torque shop.

Get the Right Mono Pump Rotor Today

Looking for a mono pump rotor that won’t let you down under pressure? Contact the team that understands flow, fit, and performance.

📞 Call MultiTorque on 1300 726 525

🌐 Visit www.multitorque.com.au

🔗 Follow us on LinkedIn

📧 Email: sales@multitorque.com