In heavy industry, mining, marine, and energy sectors, reliable engine starting isn’t optional—it’s critical. That’s where the pneumatic air starter comes in. Designed for harsh environments and demanding applications, pneumatic air starters offer safe, spark-free, and dependable starting power for diesel and gas engines without relying on batteries or electrical systems.

At MultiTorque, we supply, service, and rebuild pneumatic air starters across Australia. Whether you’re running a Caterpillar engine deep in the Pilbara or a backup generator offshore, we’ve got the air-powered starting systems to keep your operation moving.

🔗 Visit MultiTorque Homepage

🔗 Follow MultiTorque on LinkedIn

What Is a Pneumatic Air Starter?

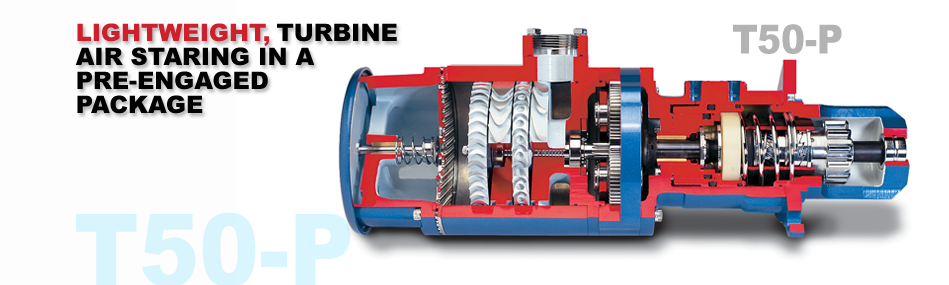

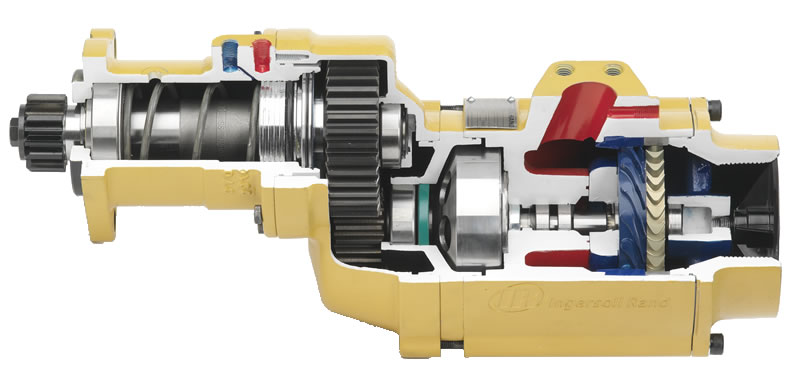

A pneumatic air starter is a compact, high-torque motor that uses compressed air to crank diesel or gas engines. Unlike electric starters that require batteries or wiring, pneumatic air starters use stored compressed air to engage the engine’s flywheel and initiate combustion.

They’re widely used in applications where:

- Electrical components pose explosion risks

- Batteries are unreliable or impractical

- Frequent engine starts are required

- Harsh weather or remote conditions are involved

From mining machinery to marine engines to emergency power systems, pneumatic air starters are the go-to solution for rugged reliability.

How Does a Pneumatic Air Starter Work?

The system is simple but powerful:

- Compressed air is stored in a reservoir tank.

- When the operator activates the system, air flows through a control valve into the starter motor.

- The motor spins a pinion gear, which engages the engine’s flywheel.

- The flywheel cranks the engine until it starts.

- Once running, the gear disengages automatically.

No electricity. No sparks. Just clean, mechanical power using air.

Key Benefits of Pneumatic Air Starters

✅ 1. Spark-Free and Explosion-Safe

Pneumatic starters are ideal for use in hazardous zones (ATEX-rated or Class 1 Div 1 environments) where electrical sparks could trigger explosions.

✅ 2. Cold-Weather Reliability

Unlike batteries that degrade in freezing conditions, air starters maintain full torque in extreme cold or heat.

✅ 3. Low Maintenance and Long Life

No electrical circuits. Minimal moving parts. Less to go wrong. With proper filtration and lubrication, pneumatic air starters deliver long service intervals.

✅ 4. Compact and Lightweight

Compared to hydraulic or electric starters, pneumatic air starters are often smaller and lighter, reducing engine weight and improving installation flexibility.

✅ 5. Multiple Starts Without Recharging

As long as there’s compressed air in the tank, pneumatic starters can crank the engine multiple times—perfect for remote or backup systems.

Common Applications

Pneumatic air starters are found in:

- Mining & Earthmoving Equipment

(e.g., diesel compressors, loaders, dozers) - Oil & Gas Installations

(e.g., drilling rigs, gas turbines) - Marine Vessels & Offshore Platforms

(e.g., lifeboat engines, pumps) - Standby Generators & Power Systems

(e.g., hospitals, telecom sites, refineries) - Military & Tactical Vehicles

Supported Brands and Engines

At MultiTorque, we supply and service air starters compatible with:

Starter Brands:

- Ingersoll Rand

- TDI (TurboTwin)

- Gali

- Startmaster

- Pow-R-Quik

Engine Brands:

- Cummins

- Caterpillar (CAT)

- Detroit Diesel

- Deutz

- MTU

- Perkins

- John Deere

We also provide mounting kits, valves, air filters, lubricators, and rebuild kits for complete system support.

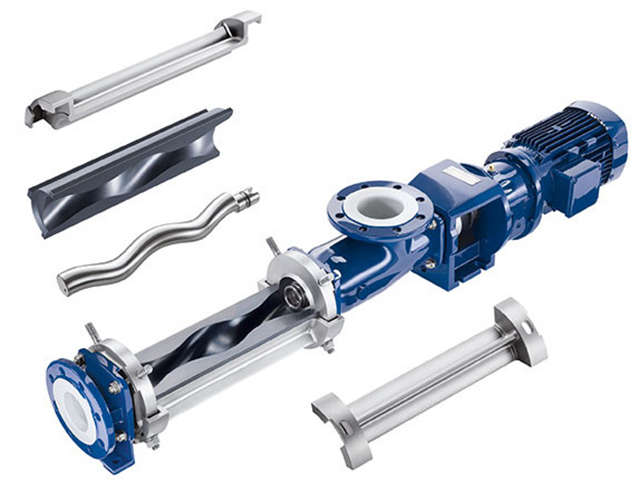

Pneumatic Starter System Components

A complete pneumatic starter system typically includes:

- Pneumatic air starter motor

- Air reservoir tank

- Control valve & activation button

- Filters & lubricators

- Check valves & safety relief valves

- Flexible hose assemblies & fittings

- Mounting hardware for your specific engine

Need help designing a system? MultiTorque can engineer full starter setups tailored to your machinery.

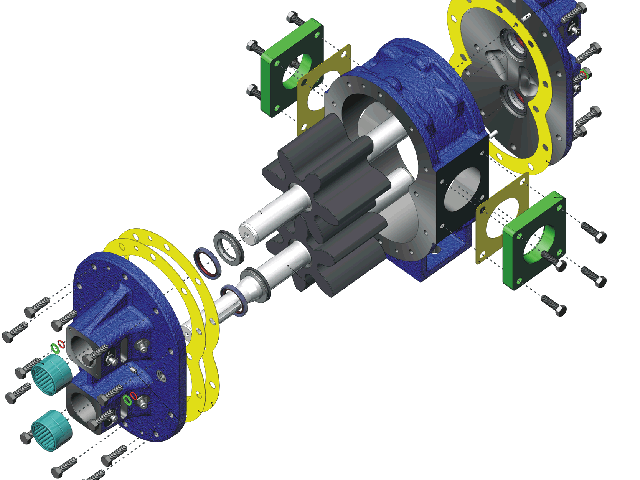

Service & Repairs by MultiTorque

MultiTorque offers nationwide support for all pneumatic air starters. Our workshop and mobile teams can:

- Inspect and test starter motor functionality

- Rebuild units with OEM or aftermarket parts

- Replace pinion gears, bearings, seals, and shafts

- Clean and reseal valves and regulators

- Pressure-test for leaks and efficiency

- Retrofit air starters to non-standard engines

Whether you’re in Brisbane, Perth, or a remote job site, MultiTorque has the tools and expertise to keep you running.

Why Choose MultiTorque?

- ✅ 15+ years of air starter experience

- ✅ Experts in diesel, pneumatic, and mechanical systems

- ✅ Fast sourcing of parts and full assemblies

- ✅ OEM and aftermarket options available

- ✅ Commitment to safety, compliance, and performance

We don’t just sell equipment—we back it with knowledge, service, and long-term support.

Get a Quote for Your Pneumatic Air Starter

Need a pneumatic air starter today? Looking to upgrade an unreliable electric system? Talk to MultiTorque.

📞 Call us now: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

🔗 Follow us on LinkedIn: MultiTorque Industries

Final Thoughts

The pneumatic air starter is the gold standard for dependable engine starts in tough, remote, or hazardous environments. With fast torque, minimal maintenance, and spark-free safety, it’s a solution trusted across the world.

At MultiTorque, we help Australian industries stay up and running with tailored pneumatic starting solutions, backed by real-world experience and premium service.