Bearings are essential components in machinery, ensuring smooth rotation, reducing friction, and extending equipment life. Choosing the right bearing suppliers is critical for maintaining reliable operations in industrial and agricultural settings. MultiTorque is a trusted Australian supplier of high-quality bearings, pumps, and related components, offering durable solutions and expert support for businesses across the country.

For trusted bearing suppliers and high-quality industrial components, contact MultiTorque today on 1300 726 525 or email sales@multitorque.com. Discover our full range of pumps, skids, and bearings at www.multitorque.com.au and stay updated with industry insights on LinkedIn.

Why Quality Bearings Matter

Bearings play a crucial role in mechanical systems by:

- Reducing friction – Allowing shafts and moving parts to operate efficiently.

- Supporting loads – Carrying both radial and axial forces in machinery.

- Extending equipment lifespan – Minimising wear and tear on critical components.

- Maintaining precision – Ensuring smooth and accurate operation in pumps, motors, and industrial equipment.

Choosing high-quality bearings from reputable suppliers is vital to avoid unexpected failures, costly downtime, and reduced efficiency.

MultiTorque: Trusted Bearing Suppliers

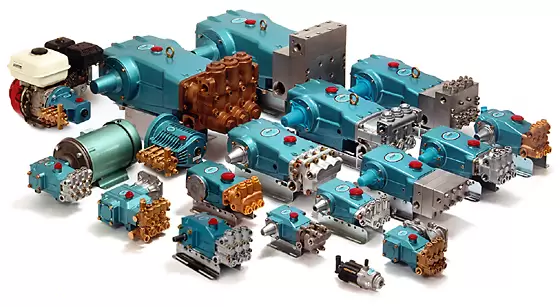

MultiTorque has over 15 years of experience supplying industrial and agricultural clients with premium components, including bearings. Our range includes:

- Ball Bearings – For high-speed applications with minimal friction.

- Roller Bearings – Suitable for heavy loads and industrial machinery.

- Spherical Bearings – For applications with misalignment or oscillating motion.

- Specialty Bearings – Designed for specific pumps, motors, and industrial equipment.

Applications of Bearings

Bearings supplied by MultiTorque are used across a wide range of applications:

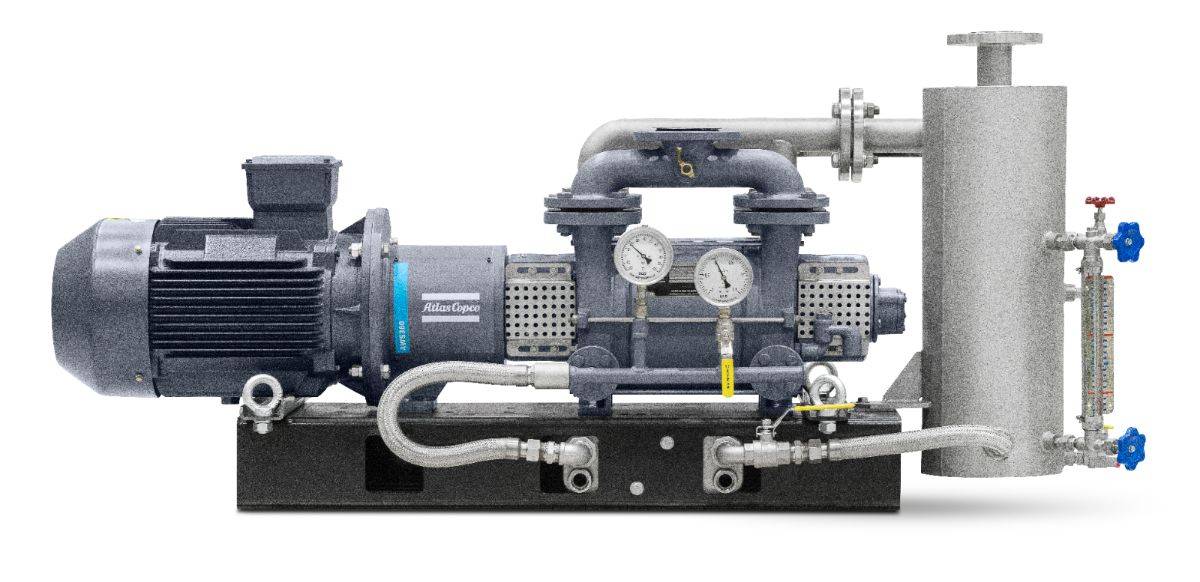

- Industrial Machinery – From mixers to conveyors, bearings ensure smooth operation and reduce energy consumption.

- Agricultural Equipment – Bearings in irrigation systems, pumps, and harvesters improve reliability and efficiency.

- Mining and Oil & Gas – Heavy-duty bearings handle extreme loads and abrasive conditions.

- Water and Wastewater Pumps – Bearings reduce friction and wear in centrifugal, progressive cavity, and submersible pumps.

- Custom Machinery – Bearings tailored to specialised equipment maintain optimal performance and longevity.

With the right bearing selection, businesses can reduce downtime, extend equipment life, and improve overall operational efficiency.

How to Choose the Right Bearing Supplier

Selecting a reliable bearing supplier is critical. Consider the following factors:

- Quality and Certification – Ensure bearings meet Australian and international standards.

- Range of Products – Access to different bearing types for various applications.

- Technical Support – Expert guidance on selecting and maintaining bearings.

- Availability – Fast delivery and support to minimise downtime.

- Integration – Compatibility with pumps, motors, and machinery supplied by the same provider.

MultiTorque stands out as a supplier that meets all these criteria, providing reliable, high-quality bearings and unmatched technical support.

Maintenance Tips for Bearings

Proper bearing maintenance ensures longevity and reduces operational issues:

- Regular Inspection – Check for wear, noise, and vibration in bearings.

- Lubrication – Apply correct grease or oil based on the manufacturer’s recommendations.

- Alignment Checks – Ensure shafts and housings are properly aligned to prevent premature wear.

- Temperature Monitoring – Excessive heat can indicate overloading or lubrication issues.

- Replacement Schedule – Replace worn bearings promptly to avoid damage to associated equipment.

MultiTorque provides guidance, technical support, and genuine replacement bearings to keep your machinery running smoothly.

Advantages of Partnering with MultiTorque

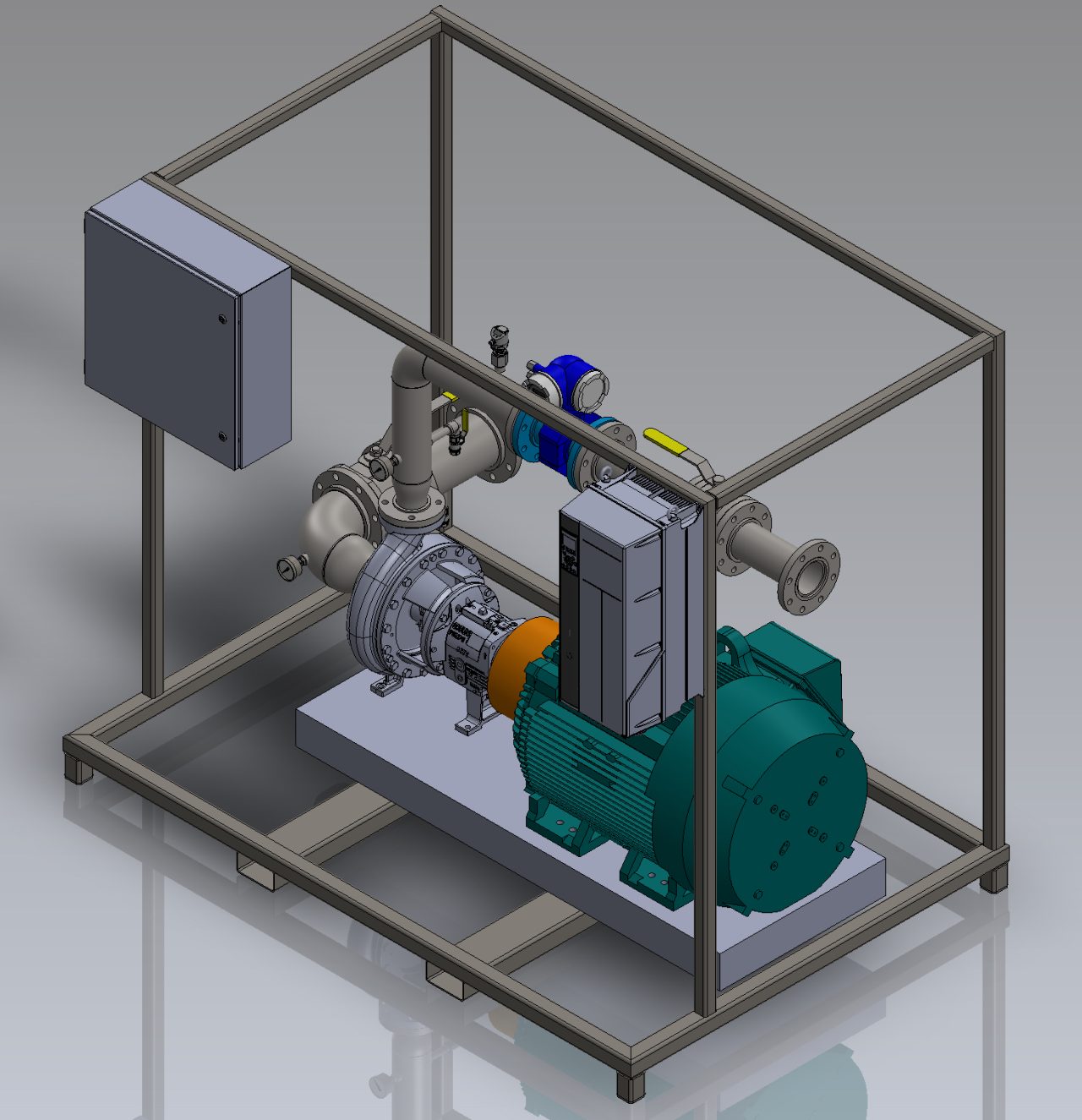

Working with MultiTorque for bearings and complementary equipment provides significant advantages:

- Expertise – Over 15 years serving industrial and agricultural clients across Australia.

- Comprehensive Solutions – Bearings, pumps, and skids from trusted brands in one place.

- Customisation – Bearings and pump solutions tailored to unique operational requirements.

- Nationwide Support – From Perth to Brisbane, MultiTorque provides timely assistance.

- Premium Quality – High-performance bearings that reduce maintenance costs and improve reliability.

Stay connected with MultiTorque on LinkedIn for updates on new products, technical insights, and industry news.

Conclusion

Selecting the right bearing suppliers is crucial for reliable, efficient, and safe machinery operation. MultiTorque provides premium bearings, technical expertise, and complementary pump solutions to meet the needs of industrial, agricultural, and mining clients across Australia. By choosing high-quality components and expert guidance, businesses can reduce downtime, enhance productivity, and extend the life of their equipment.

Call to Action

For trusted bearing suppliers and high-quality industrial components, contact MultiTorque today on 1300 726 525 or email sales@multitorque.com. Discover our full range of pumps, skids, and bearings at www.multitorque.com.au and stay updated with industry insights on LinkedIn.