Wilo circulation pumps are widely used in residential, commercial, and industrial applications for heating, cooling, and water circulation systems. Over time, pumps may experience wear, reduced performance, or failure due to mechanical issues, electrical faults, or harsh operating conditions. When this happens, professional Wilo circulation pump repair is essential to restore efficiency, prevent downtime, and extend the life of your system.

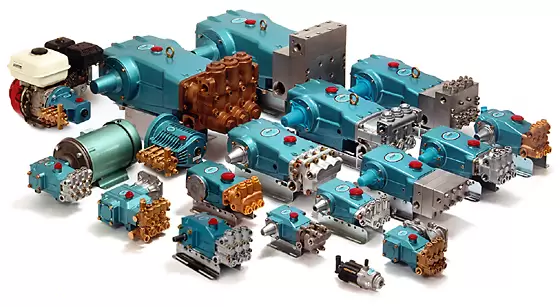

MultiTorque is a trusted Australian provider of pump repair services, specialising in Wilo pumps and other leading brands. With over 15 years of experience, our expert technicians deliver reliable repairs, high-quality replacement parts, and in-house service to keep your circulation pumps running at peak performance.

Why Timely Wilo Circulation Pump Repair Matters

Neglecting issues with circulation pumps can lead to:

- Reduced system efficiency and higher energy consumption

- Overheating or damage to connected equipment

- Increased maintenance costs due to progressive wear

- Downtime in critical operations such as industrial processes or commercial facilities

Professional repair ensures your Wilo pump operates reliably, maintains flow rates, and prevents costly interruptions.

Common Issues with Wilo Circulation Pumps

MultiTorque technicians commonly encounter the following problems in Wilo circulation pumps:

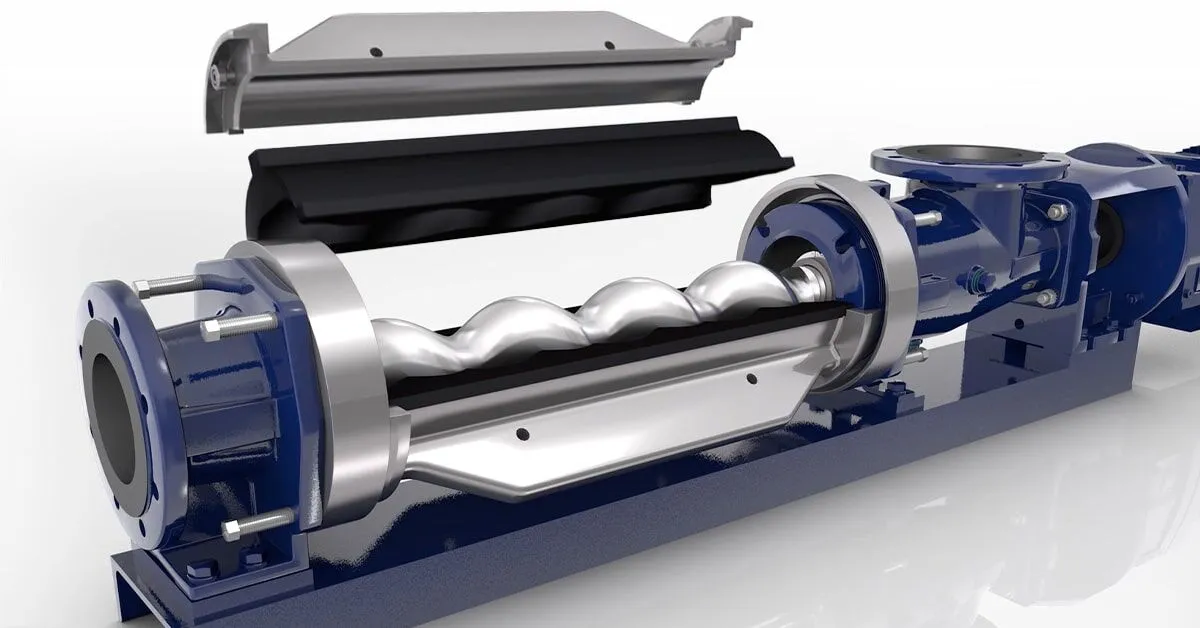

- Mechanical Wear

- Worn bearings, impellers, or shafts can reduce pump performance.

- Our in-house workshops provide precision repair and replacement of worn components (see industrial pump skid services).

- Seal Failures

- Leaks from mechanical seals or gaskets can damage surrounding equipment.

- MultiTorque supplies high-quality seals and ensures proper installation.

- Electrical Issues

- Faulty motors, wiring, or control systems can prevent the pump from operating.

- Our technicians diagnose and repair electrical faults to restore performance (see chemical pump skid solutions).

- Corrosion or Abrasion

- Pumps handling water with minerals or chemicals may experience corrosion or erosion.

- Using genuine parts and proper maintenance can prevent long-term damage (read about centrifugal pump skid solutions).

MultiTorque’s Wilo Circulation Pump Repair Process

Our repair process is designed to ensure efficiency, reliability, and compliance with manufacturer standards:

- Inspection and Diagnosis

- Each pump is carefully inspected to identify mechanical, electrical, and hydraulic issues.

- Our team provides a detailed assessment and repair recommendation.

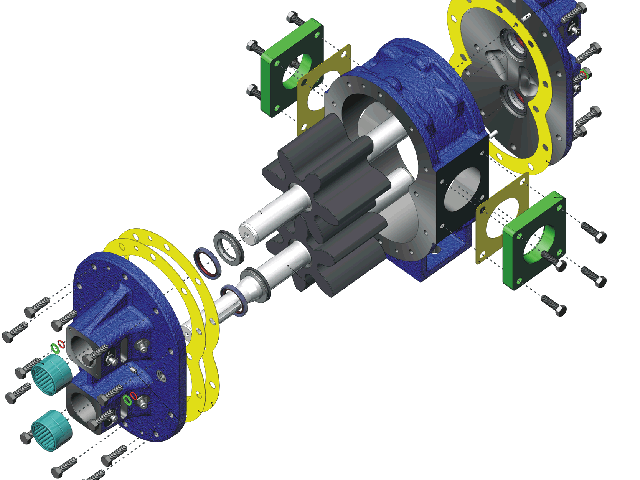

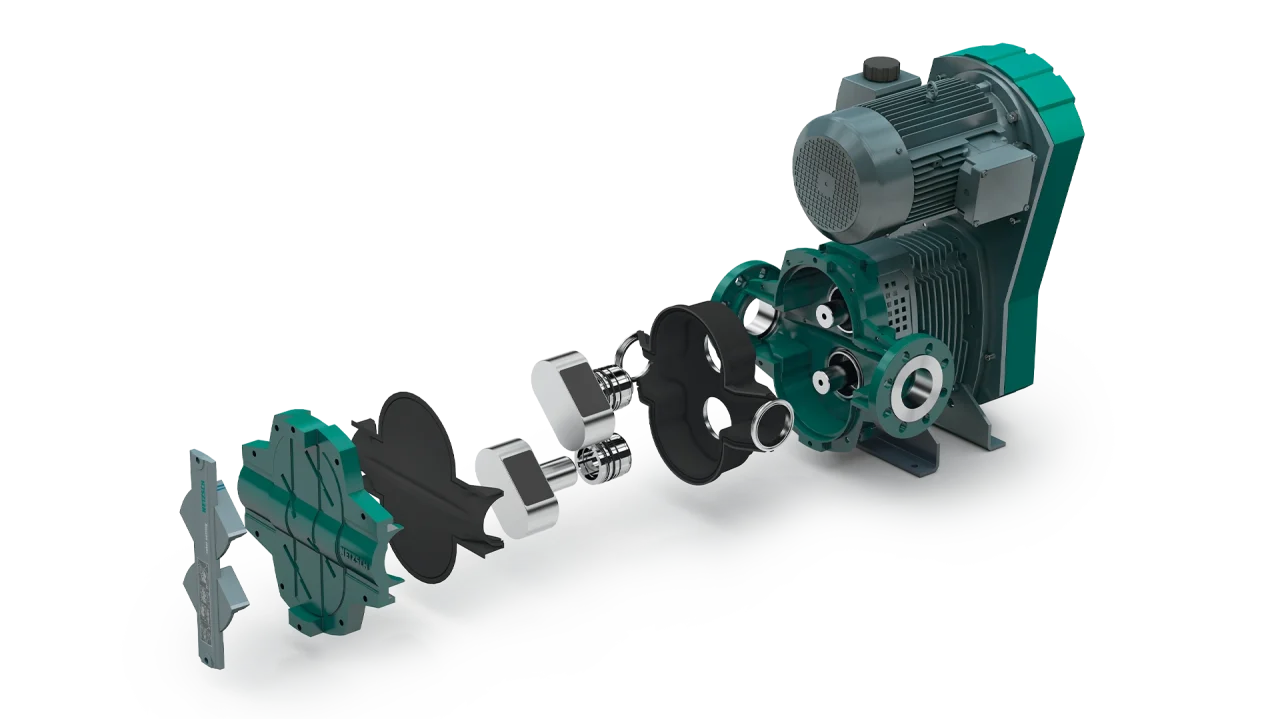

- Disassembly and Cleaning

- Pumps are dismantled, cleaned, and prepared for component inspection.

- Worn parts are identified, measured, and compared to specifications.

- Replacement of Worn Parts

- Bearings, seals, impellers, and shafts are replaced with genuine high-quality parts.

- For specialised needs, custom components can be fabricated (see Mono progressive cavity pump solutions).

- Reassembly and Testing

- Pumps are reassembled with precision, tested for performance, and checked for leaks or electrical faults.

- Flow rates, pressure, and efficiency are verified to meet operational standards.

- Installation Support and Advice

- MultiTorque technicians provide guidance on proper installation, commissioning, and ongoing maintenance to prevent future failures.

Benefits of Choosing MultiTorque

- Experienced Technicians

- Our team specialises in Wilo pump repair and understands the nuances of circulation systems.

- In-House Workshop

- Repairs are conducted in-house, ensuring quality control and fast turnaround times.

- Nationwide Service

- MultiTorque serves clients across Australia, from Perth to Brisbane, offering reliable logistics and support.

- Genuine Parts and Expertise

- Only high-quality parts are used, and repair work follows manufacturer specifications for longevity and performance.

- Custom Solutions

- For complex or specialised systems, we provide tailored repair solutions, pump modifications, or complete pump skids (industrial pump skid solutions).

Maintenance Tips to Extend Pump Life

Even after professional repair, proper maintenance is crucial to prolong the life of your Wilo circulation pump:

- Regular Inspections: Check for unusual noises, vibration, or leaks.

- Lubrication: Ensure bearings and moving components are adequately lubricated.

- Monitor System Conditions: Avoid running pumps dry or under excessive pressure.

- Clean Water Supply: Reduce sediment, debris, or corrosive chemicals.

- Scheduled Servicing: Work with MultiTorque to plan periodic checks and preventive maintenance.

Industries Served

MultiTorque provides Wilo circulation pump repair services across multiple industries:

- Industrial Manufacturing: Water circulation, cooling, and processing applications

- Commercial Buildings: HVAC, hot water, and water supply systems

- Agriculture & Irrigation: Circulation for water transfer and irrigation systems

- Mining & Resources: Circulation pumps for dewatering, slurry, and process water

Our wide-ranging expertise ensures your pumps operate efficiently regardless of the application.

Contact MultiTorque

For reliable Wilo circulation pump repair services in Australia, contact MultiTorque today. Our expert team provides inspections, repairs, maintenance, and advice to ensure your pumps deliver peak performance.

📞 Phone: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: www.multitorque.com.au

🔗 LinkedIn: MultiTorque Industries

Trust MultiTorque for high-quality Wilo pump repairs, genuine parts, and nationwide support, keeping your circulation systems running reliably. Wilo Circulation Pump Repair Wilo Circulation Pump Repair Wilo Circulation Pump Repair