When it comes to dependable pumping equipment for remote or demanding applications, a gas powered water pump is one of the most versatile options available. Unlike electric pumps, which require access to mains power, gas powered units are portable, powerful, and built to perform in harsh conditions. Whether you’re managing water flow on a farm, handling dewatering projects on a construction site, or supporting emergency flood control, gas powered water pumps deliver the flexibility and strength required to get the job done.

In Australia, where agricultural and industrial operations often take place in challenging environments, having access to reliable pumping equipment can make all the difference. MultiTorque is a trusted supplier of high-performance pumps nationwide, with extensive experience in sourcing, servicing, and supplying solutions tailored to critical applications.

What Is a Gas Powered Water Pump?

A gas powered water pump is designed to move large volumes of water quickly and efficiently, powered by a petrol engine. These pumps are commonly used in settings where electricity is not readily available, making them ideal for remote agricultural properties, mines, and emergency response situations.

Key benefits of a gas powered water pump include:

- Portability – easy to transport to remote worksites.

- High flow rates – capable of moving thousands of litres per hour.

- Independence from electricity – critical during blackouts or in off-grid locations.

- Durability – engineered to withstand rugged operating conditions.

Applications of Gas Powered Water Pumps

One of the strengths of a gas powered water pump is its versatility. Industries across Australia rely on these pumps for a wide range of uses, including:

- Agriculture – irrigation, livestock watering, and transferring water across large properties.

- Construction and mining – dewatering trenches, pits, and work areas.

- Flood control and emergency services – rapid water removal in emergencies.

- Industrial use – transferring water and fluids where mobility is essential.

For farmers in particular, gas powered pumps are invaluable for maintaining consistent water supply during dry conditions. In mining and industrial environments, they help ensure operations continue without interruption.

Why Gas Powered Water Pumps Stand Out

While there are many types of pumps available, gas powered water pumps are preferred in situations where:

- Power sources are limited – no need for mains electricity or generators.

- High flow capacity is required – designed to handle large-scale water transfer.

- Reliability is critical – robust engines and components ensure consistent performance.

Compared to electric pumps, gas powered models offer superior mobility and flexibility, making them essential for industries that require pumping solutions on the move.

Choosing the Right Gas Powered Water Pump

When selecting a gas powered water pump, several factors should be considered:

- Flow rate – measured in litres per minute or hour, determines how much water can be moved.

- Head height – the maximum height the pump can lift water, crucial for irrigation and transfer.

- Durability of parts – strong seals, quality bearings, and heavy-duty housings extend pump life.

- Ease of maintenance – access to spare parts and service support ensures long-term reliability.

MultiTorque works closely with industries to supply gas powered water pumps that match specific operational needs. From agricultural irrigation to heavy-duty dewatering, every pump is selected to ensure maximum efficiency and durability.

Related Pump Solutions

In addition to gas powered pumps, MultiTorque supplies a wide range of pumping systems and parts for industries across Australia. For example:

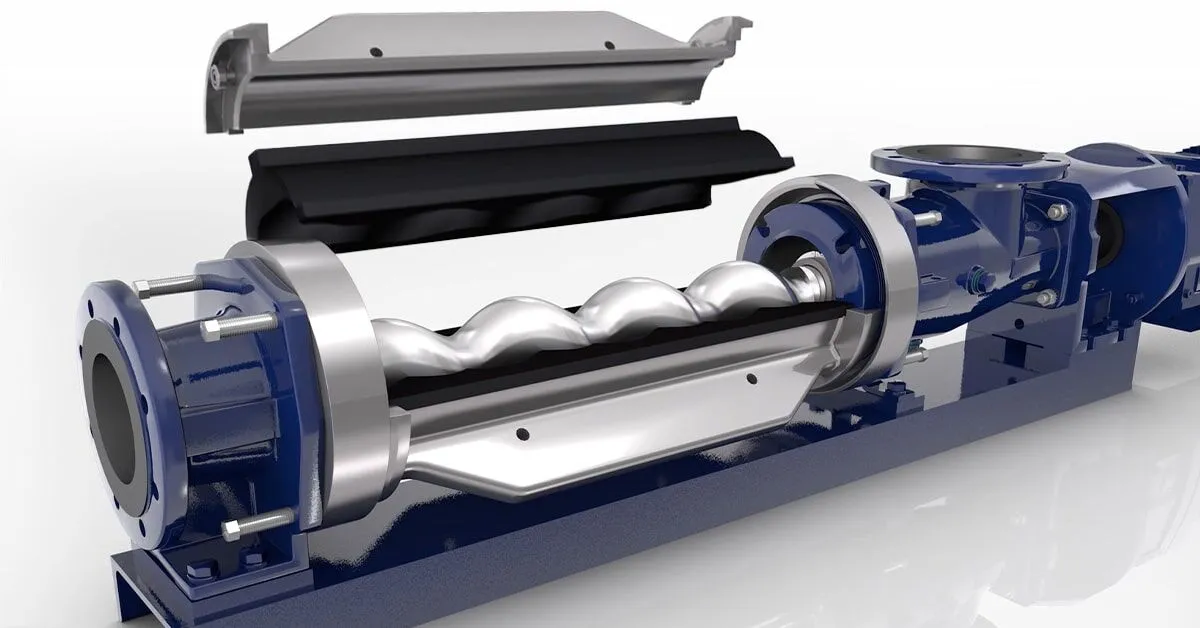

- NETZSCH progressive cavity pumps – engineered for handling viscous and abrasive fluids with precision.

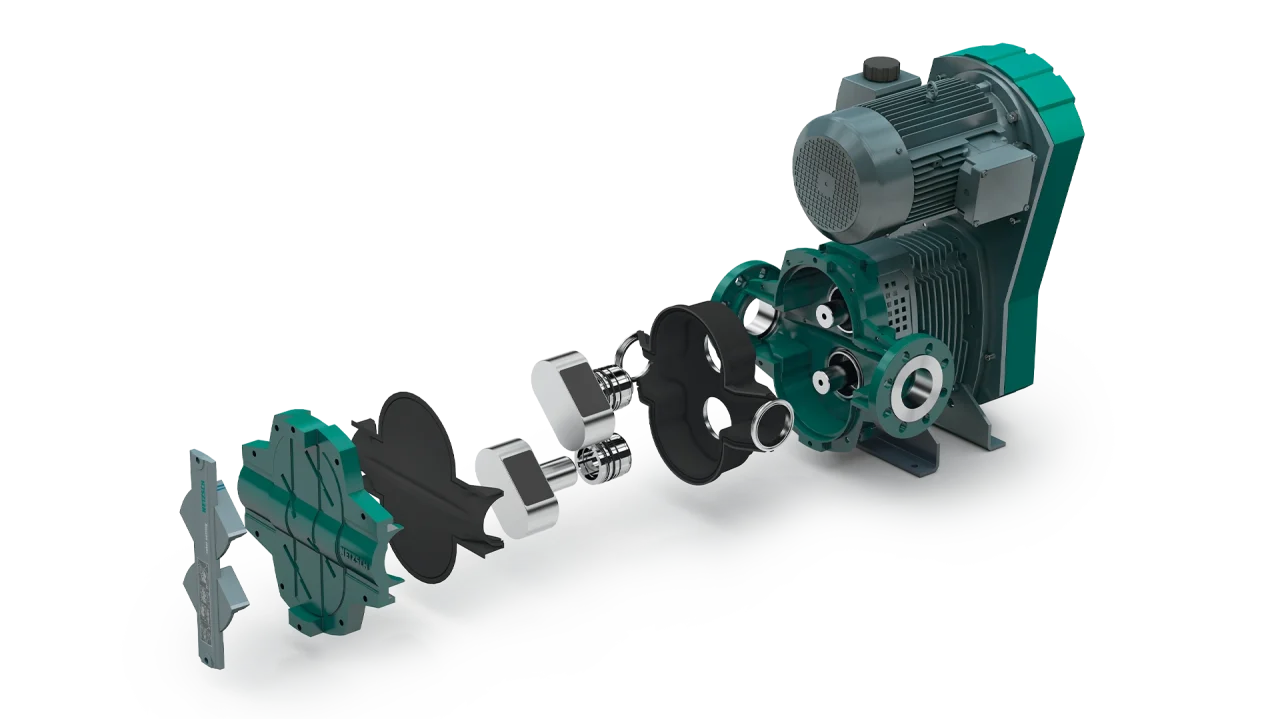

- SEEPEX pumps – known for modular designs and efficient spare parts replacement.

- Mono progressive cavity pumps – widely used in wastewater and industrial applications.

- NOV Mono pumps – trusted solutions for mining, oil, and gas industries.

By integrating these solutions with gas powered water pumps, MultiTorque provides comprehensive pumping systems designed to meet Australia’s toughest operational challenges.

Maintenance and Spare Parts

Like all mechanical equipment, gas powered water pumps require regular maintenance to perform at their best. Key areas to monitor include:

- Engine servicing – oil changes, spark plug replacement, and air filter cleaning.

- Pump seals and bearings – essential for leak prevention and smooth operation.

- Impellers and casings – subject to wear when handling abrasive materials.

Sourcing high-quality spare parts ensures pumps stay reliable even in harsh conditions. MultiTorque offers access to genuine components and high-performance alternatives, reducing downtime and extending equipment life.

Advantages of Partnering with MultiTorque

When you choose MultiTorque for your gas powered water pump needs, you benefit from:

- Expertise – over 15 years of experience supplying and servicing pumps across Australia.

- Custom solutions – pumps tailored to the unique requirements of your operation.

- Nationwide support – servicing clients from Brisbane to Perth.

- Access to leading brands – ensuring long-term performance and reliability.

Our commitment to safety, quality, and customer satisfaction makes MultiTorque the go-to partner for businesses that depend on reliable pumping solutions.

Stay Connected with MultiTorque

We understand that industrial and agricultural operations require more than just equipment – they need long-term partnerships. Stay updated on pump technology, industry trends, and company news by connecting with us on LinkedIn.

By sharing knowledge and expertise, we help businesses make informed decisions about their pumping systems while building stronger, more resilient operations.

Final Thoughts

In industries where efficiency and reliability are non-negotiable, a gas powered water pump is one of the most versatile and dependable tools available. Its portability, high flow capacity, and independence from electrical power make it an essential piece of equipment for agriculture, construction, mining, and emergency services.

By combining gas powered pumps with comprehensive maintenance and quality spare parts, businesses can protect their investments and maintain uninterrupted operations. With MultiTorque’s expertise and commitment to supplying only the highest-quality solutions, you can be confident in having the right equipment for any challenge.

Call to Action

For premium gas powered water pumps and expert support tailored to your needs, contact MultiTorque today. Call us on 1300 726 525 or email sales@multitorque.com. Visit our website at www.multitorque.com.au to explore our full range of pumping solutions. Stay connected with us on LinkedIn for the latest updates and industry insights.