Centrifugal pumps are widely used across industrial and agricultural sectors for transferring water and other fluids efficiently. A centrifugal pump skid provides a compact, pre-assembled solution that combines pumps, motors, piping, and control systems on a single skid. Designed for reliability, efficiency, and ease of installation, centrifugal pump skids are essential for high-demand applications. MultiTorque, a leading Australian supplier, offers customised and standard centrifugal pump skid solutions to meet diverse operational requirements.

What Is a Centrifugal Pump Skid?

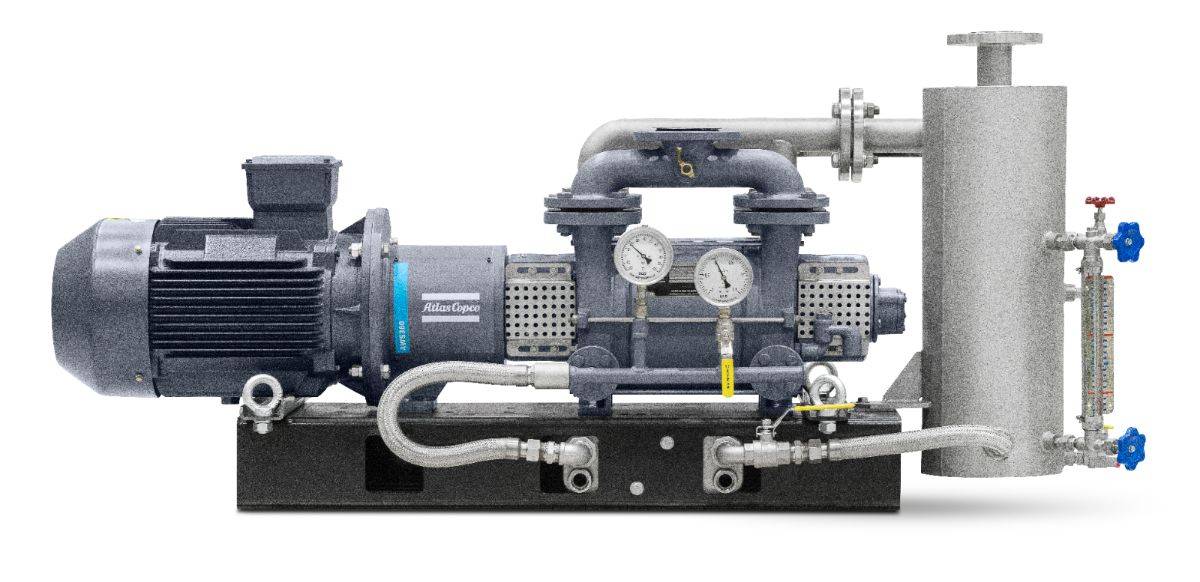

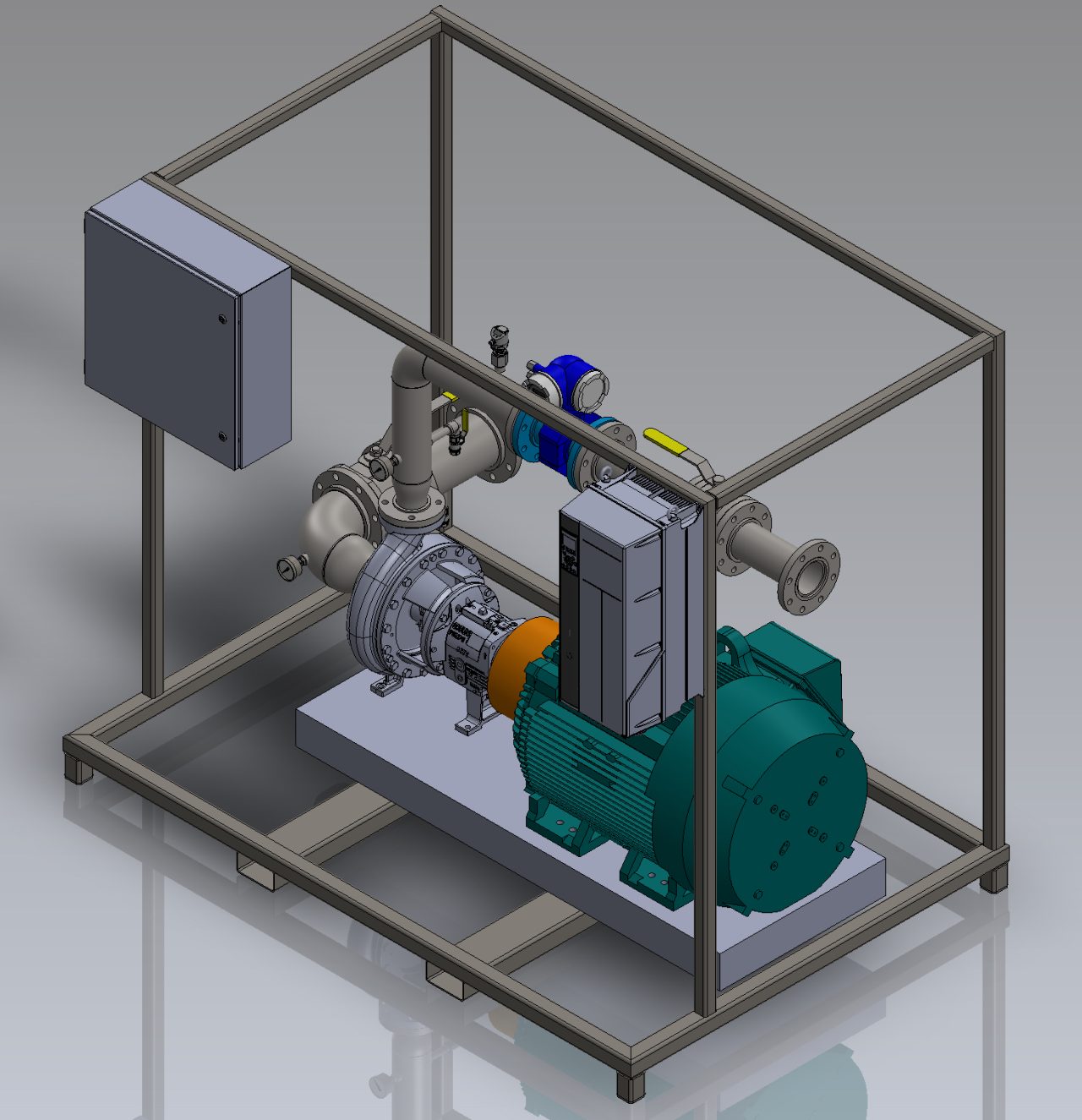

A centrifugal pump skid is a pre-assembled system that integrates one or more centrifugal pumps, motors, valves, piping, and control panels onto a single skid or frame. These skids are engineered to deliver high flow rates, consistent pressure, and dependable operation in industrial and agricultural settings.

Key features include:

- Integrated design – Pump, motor, and control system on a single skid for fast deployment.

- Customisable configuration – Pumps and motors selected for specific flow and pressure requirements.

- Durable construction – Skids built to withstand harsh industrial and agricultural environments.

- Automated control systems – Ensures consistent flow, pressure, and energy efficiency.

By using a centrifugal pump skid, operators reduce installation time, simplify maintenance, and ensure reliable fluid transfer.

Applications of a Centrifugal Pump Skid

A centrifugal pump skid is highly versatile and widely used in a variety of applications:

- Industrial Water Systems – Transfer of water in manufacturing, cooling, or processing operations.

- Agriculture – Irrigation, water distribution, and drainage in farms and greenhouses.

- Municipal Water Supply – Boosting pressure and flow in pipelines and storage systems.

- Mining and Oil & Gas – Handling process water, chemicals, or fluid transfer in demanding conditions.

- Fire Suppression Systems – Supplying reliable pressure for sprinklers and hydrants.

By deploying a centrifugal pump skid, businesses can ensure uninterrupted fluid transfer, reducing downtime and increasing operational efficiency.

Benefits of Choosing a Centrifugal Pump Skid

- High Flow Capacity

- Moves large volumes of fluid efficiently, reducing operational delays.

- Compact and Ready-to-Install

- Pre-assembled skid design saves space and installation time.

- Durable and Reliable

- Built from high-quality materials to withstand abrasive and corrosive conditions.

- Energy-Efficient Operation

- Automated control systems optimise pump performance and reduce energy costs.

- Simplified Maintenance

- Skid layout allows easy access to pumps, valves, and control components.

MultiTorque Pump Solutions

MultiTorque supplies a range of high-performance pumping solutions, including centrifugal pump skids, suitable for industrial and agricultural operations. In addition, MultiTorque provides access to complementary high-quality pumps:

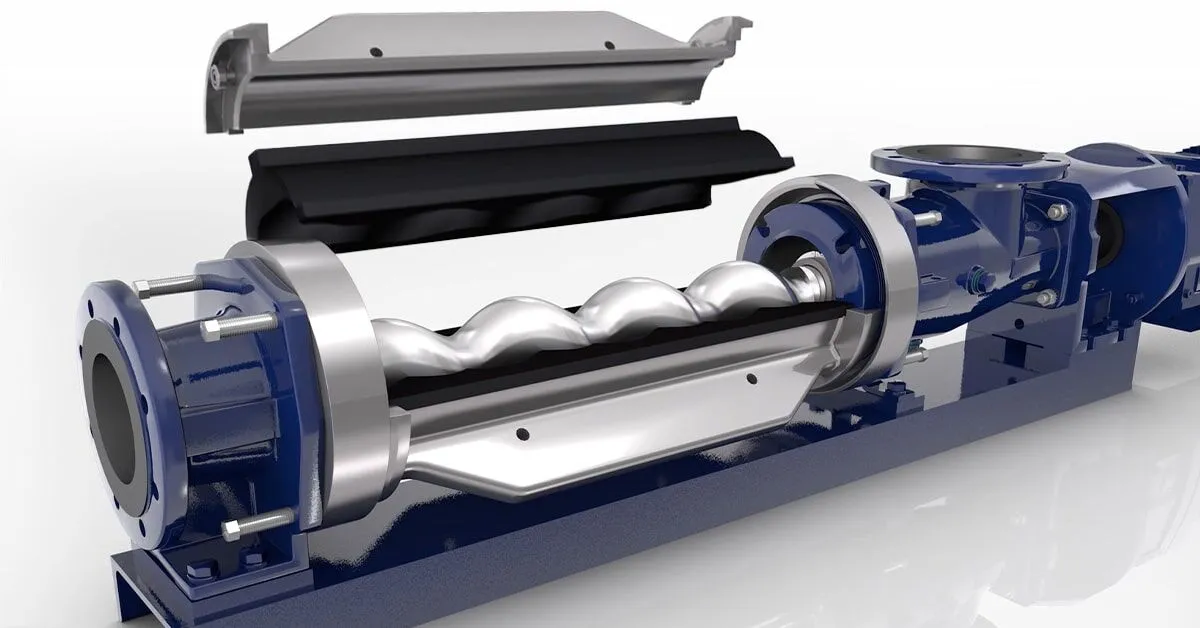

- NETZSCH progressive cavity pumps – Perfect for handling viscous and abrasive fluids.

- SEEPEX pumps – Modular and efficient for industrial applications.

- Mono progressive cavity pumps – Reliable for wastewater and industrial pumping tasks.

- NOV Mono pumps – Trusted for mining, oil, and gas operations.

Combining a centrifugal pump skid with these premium pumps ensures complete, efficient, and reliable fluid management solutions.

How to Choose the Right Centrifugal Pump Skid

Selecting the correct centrifugal pump skid is critical for operational efficiency and longevity. Key considerations include:

- Flow Rate and Pressure Requirements – Ensure the skid meets your operational demands.

- Pump Type and Capacity – Choose centrifugal pumps suitable for the fluid type and volume.

- Material Durability – Corrosion- and abrasion-resistant materials increase service life.

- Control System – Automated or manual controls maintain consistent flow and pressure.

- Maintenance Accessibility – Skid layout should allow easy access to pumps and valves.

MultiTorque works with clients to design and supply centrifugal pump skids customised to specific operational requirements.

Maintenance Tips for Centrifugal Pump Skids

Proper maintenance ensures long-lasting performance:

- Regular Inspections – Check pumps, motors, piping, and control panels for wear or damage.

- Clean Components – Remove debris, sediment, or scale buildup to maintain efficiency.

- Electrical Checks – Ensure motors and control panels are functioning correctly.

- Monitor Performance – Track flow rates and pressure to detect early warning signs of issues.

With MultiTorque’s genuine spare parts and technical support, maintaining a centrifugal pump skid is simple and reduces downtime.

Advantages of Partnering with MultiTorque

Choosing MultiTorque for your centrifugal pump skid offers multiple advantages:

- Expertise – Over 15 years supplying and servicing pumps and skids across Australia.

- Custom Solutions – Skids designed to meet specific industrial and agricultural requirements.

- Nationwide Support – From Perth to Brisbane, MultiTorque provides timely assistance.

- Access to Premium Brands – Ensures reliable, long-lasting performance.

Stay connected with MultiTorque on LinkedIn for industry updates, technical advice, and product news.

Conclusion

A centrifugal pump skid is an essential solution for industrial, agricultural, and municipal applications requiring efficient, reliable fluid transfer. With integrated pumps, motors, piping, and control systems, these skids deliver consistent performance while reducing installation complexity and maintenance time.

Paired with MultiTorque’s high-performance pump range, centrifugal pump skids provide a complete and reliable fluid management system. Choosing the right skid and maintaining it properly ensures long-term operational success.

Call to Action

For expert advice and reliable centrifugal pump skids tailored to your operational needs, contact MultiTorque today on 1300 726 525 or email sales@multitorque.com. Explore our full range of pump solutions at www.multitorque.com.au and stay updated with industry insights on LinkedIn.