In industrial operations, reliable fluid handling is essential to maintain efficiency, safety, and productivity. Heavy duty industrial pumps are designed to meet the demands of challenging applications, handling high volumes, viscous fluids, and abrasive materials with consistent performance. At MultiTorque, we supply, service, and rebuild heavy duty industrial pumps tailored to the unique requirements of Australian industries.

With over 15 years of experience, MultiTorque has become a trusted provider of premium pumps, offering solutions for mining, chemical processing, agriculture, oil & gas, and manufacturing sectors.

📞 Phone: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: www.multitorque.com.au

🔗 LinkedIn: MultiTorque Industries

What Are Heavy Duty Industrial Pumps?

Heavy duty industrial pumps are engineered to deliver high performance in tough operational environments. They are built from durable materials capable of withstanding pressure, abrasion, and corrosion while maintaining efficiency. These pumps can handle various fluids, from clean water to chemicals, slurry, and oils.

Key features include:

- Robust Construction: Designed to withstand harsh industrial conditions.

- High Flow Capacity: Capable of transferring large volumes efficiently.

- Versatile Applications: Suitable for chemical, mining, and agricultural processes.

- Durability: Built to reduce maintenance and extend operational life.

MultiTorque ensures that each pump is matched to your operational requirements, optimising flow, pressure, and reliability.

Applications of Heavy Duty Industrial Pumps

Heavy duty industrial pumps are essential across multiple industries:

- Mining and Resources: Handling slurry, wastewater, and abrasive fluids efficiently (see centrifugal pump skid solutions).

- Chemical Processing: Transferring aggressive or hazardous chemicals safely (read about chemical pump skid systems).

- Oil & Gas: Managing fuel, oils, and lubricants under demanding conditions (read about oil and gas pump solutions).

- Agriculture: Irrigation, water transfer, and chemical application.

- Manufacturing: Lubrication, cooling, and fluid circulation systems.

These pumps ensure continuous operation, even under challenging conditions where reliability is critical.

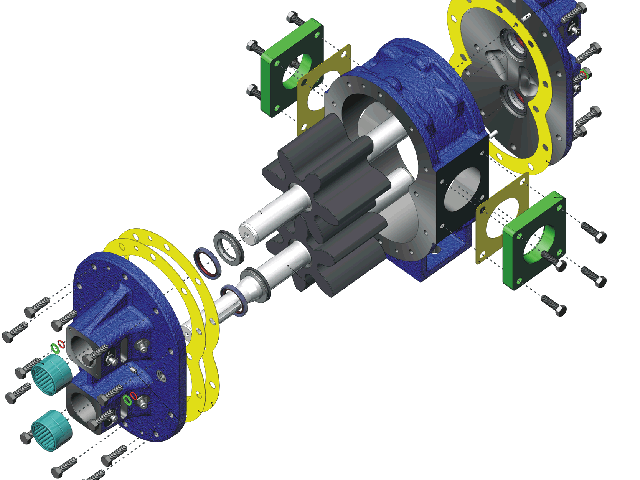

Types of Heavy Duty Industrial Pumps

MultiTorque offers a variety of heavy duty industrial pumps to suit different applications:

- Centrifugal Pumps: Ideal for high flow applications and consistent pressure delivery (see industrial pump skid solutions).

- Positive Displacement Pumps: Suitable for precise dosing of viscous or chemical fluids.

- Gear Pumps: Accurate fluid transfer for lubricants and oils (read about gear pump displacement).

- Progressive Cavity Pumps: Efficient handling of sludge, slurry, or viscous materials (read more about progressive cavity pumps).

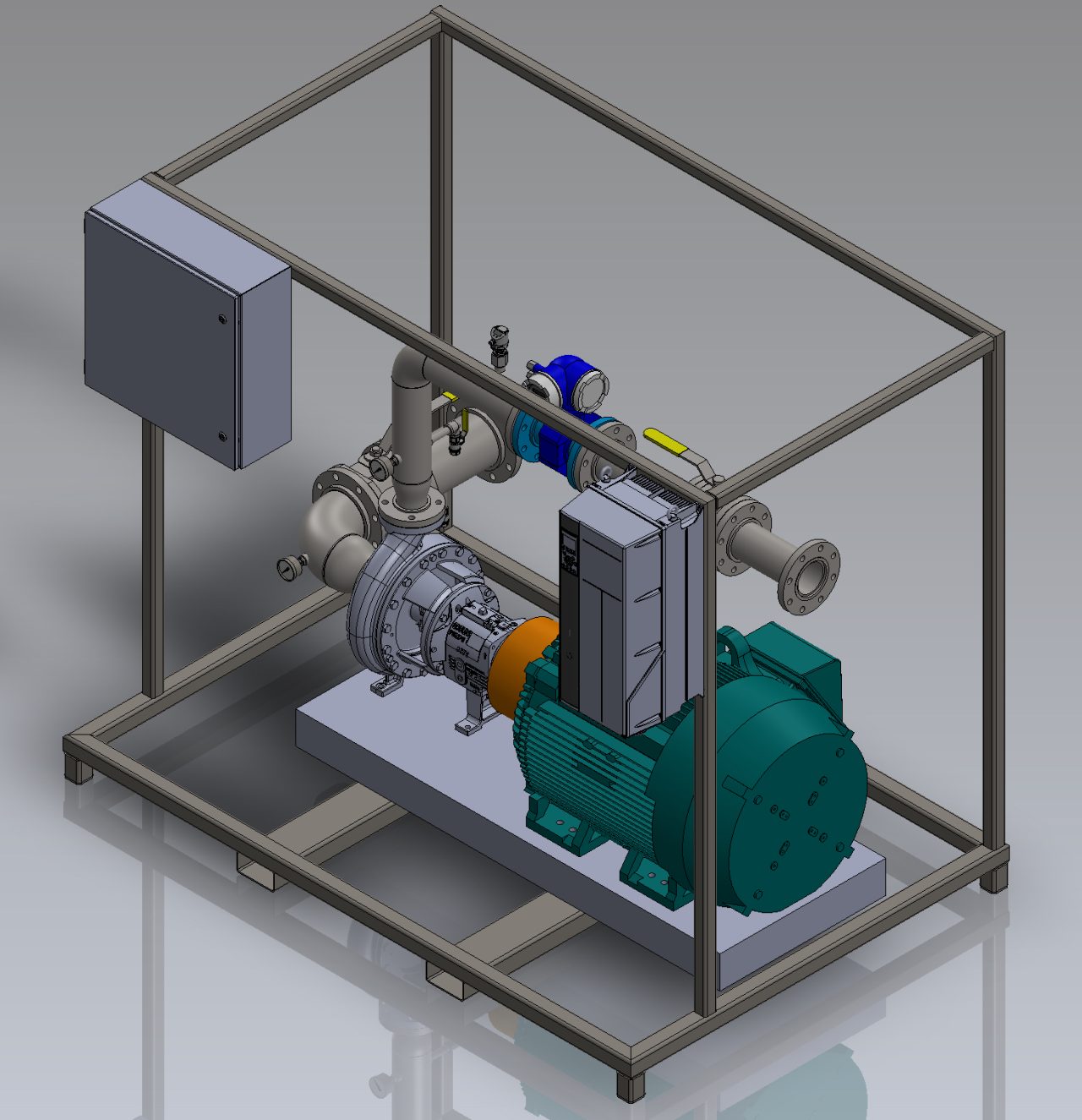

- Skid-Mounted Pump Systems: Complete integrated units for easy deployment and operation.

Each type of pump is selected based on the fluid properties, volume, pressure requirements, and site conditions to ensure optimal performance.

Features and Benefits

Heavy duty industrial pumps from MultiTorque offer numerous advantages:

- High Efficiency: Minimises energy consumption while maintaining flow rates.

- Corrosion-Resistant Materials: Handles chemical and abrasive fluids without premature wear.

- Flexible Installation: Can be skid-mounted or integrated into existing systems.

- Low Maintenance: Reduces downtime and long-term operational costs.

- Custom Solutions: MultiTorque can tailor pump solutions for unique industrial requirements.

By using these pumps, businesses can maintain high productivity and reliability, even under extreme conditions.

Servicing and Support

MultiTorque provides comprehensive in-house servicing and rebuilds for heavy duty industrial pumps. Our services include:

- Replacement of worn parts, seals, and bearings

- Cleaning and reconditioning of pump housings

- Performance testing and verification

- Expert technical advice on installation, operation, and maintenance

By relying on MultiTorque for servicing, businesses extend the life of their pumps and reduce unexpected downtime.

Industries That Trust MultiTorque

Heavy duty industrial pumps from MultiTorque are trusted by:

- Mining & Resources: Efficient slurry and water transfer for demanding environments.

- Chemical & Processing Plants: Safe handling of aggressive chemicals.

- Oil & Gas: Reliable fuel and lubricant pumping under high pressure (see Cat pump oil).

- Agriculture & Irrigation: High-capacity water and chemical transfer.

- Manufacturing & Production: Pumping solutions for lubrication, cooling, and fluid circulation.

MultiTorque’s solutions are engineered to meet stringent industry standards and provide long-term reliability.

Why Choose MultiTorque?

Businesses choose MultiTorque for heavy duty industrial pumps because of:

- Experience: Over 15 years supplying, servicing, and rebuilding pumps.

- Expertise: Knowledge across centrifugal, progressive cavity, gear, and skid-mounted systems.

- Custom Solutions: Tailored pump configurations and integrated skid systems.

- National Support: Branches in Perth and Brisbane with in-house workshops.

- Customer Commitment: Reliability, safety, and long-term partnerships.

MultiTorque delivers pump solutions that are durable, efficient, and built for demanding industrial applications.

Contact MultiTorque

For premium heavy duty industrial pumps, reach out to MultiTorque to discuss your requirements and discover tailored solutions.

📞 Phone: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: www.multitorque.com.au

🔗 LinkedIn: MultiTorque Industries

Invest in MultiTorque heavy duty industrial pumps to ensure your operations are safe, reliable, and high-performing.