When it comes to powering demanding operations in mining, construction, agriculture, and dewatering, one piece of equipment consistently stands out: the diesel pump skid. Built for durability, mobility, and efficiency, these pump systems provide industries with reliable solutions to move water, slurry, and other fluids in the harshest conditions.

📍 Visit us online: www.multitorque.com.au

📞 Call us on: 1300 726 525

📧 Email: sales@multitorque.com

🔗 Connect with us: MultiTorque LinkedIn

At MultiTorque Industries, we specialise in supplying, servicing, and repairing high-performance pumps across Australia. With more than 15 years of experience in the field, our team has worked with a wide range of pump configurations, including diesel pump skids that meet the unique needs of Australian industry.

📍 Visit us online: www.multitorque.com.au

📞 Call us on: 1300 726 525

📧 Email: sales@multitorque.com

🔗 Connect with us: MultiTorque LinkedIn

What is a Diesel Pump Skid?

A diesel pump skid is a self-contained pumping unit that mounts a pump and a diesel engine onto a sturdy steel skid frame. The skid frame provides stability, portability, and protection, making it easier to transport and deploy the pump to different job sites.

Unlike electric pumps, which require access to power infrastructure, a diesel pump skid can operate independently in remote areas. This makes it an ideal choice for mining camps, dewatering pits, construction projects, and emergency water transfer applications.

The skid frame often includes lifting points, forklift slots, or trailer mounting options, giving operators the flexibility to move and position the pump where it’s needed most.

Benefits of Diesel Pump Skids

Choosing a diesel pump skid offers several advantages over other pump setups:

1. Mobility and Flexibility

Because they are self-contained units, diesel pump skids can be deployed quickly and easily. Whether the site is in the outback, at a mine, or on a construction site, operators don’t have to rely on existing infrastructure.

2. Power and Reliability

Diesel engines are known for their torque, efficiency, and durability. A diesel pump skid can deliver consistent performance in even the harshest environments.

3. Easy Maintenance

With straightforward servicing needs, diesel pump skids are designed to be rugged and user-friendly. MultiTorque’s workshop provides in-house repairs and servicing to keep pumps operating at peak condition.

4. Cost-Effective Operations

Since they do not require extensive site infrastructure, diesel pump skids can reduce setup costs and keep projects moving on time.

Industrial Applications of Diesel Pump Skids

Diesel pump skids are versatile and used across multiple industries in Australia. Common applications include:

- Mining: Dewatering pits, transferring slurry, and managing water supply on-site.

- Construction: Removing groundwater, draining flooded areas, and supporting infrastructure projects.

- Agriculture: Irrigation, stock water supply, and large-scale water transfers.

- Emergency Response: Flood management, disaster recovery, and firefighting water supply.

At MultiTorque, we understand that each industry faces different challenges. That’s why we work closely with clients to supply pumps that are correctly sized, configured, and supported for the job.

Why Choose MultiTorque for Diesel Pump Skids?

With branches in Perth and Brisbane, MultiTorque Industries has established itself as a trusted partner for businesses across the country. Here’s why customers rely on us for their diesel pump skid needs:

1. Expertise Across Pump Types

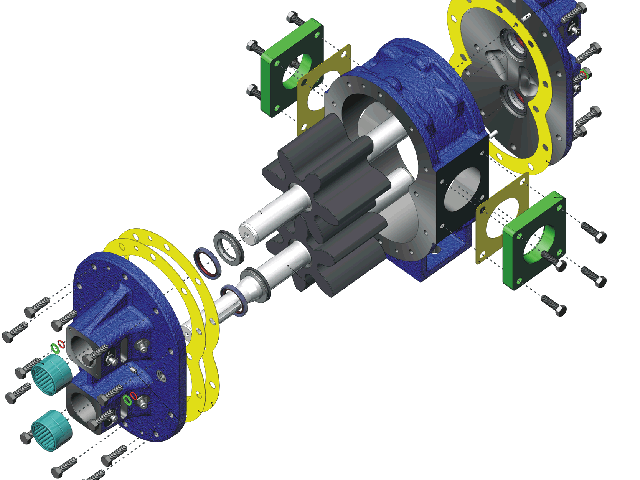

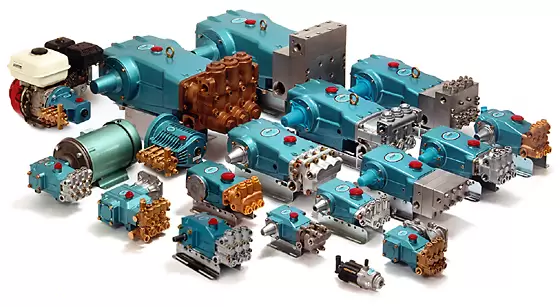

We work with centrifugal pumps, progressive cavity pumps, and other positive displacement designs, ensuring that the diesel pump skid chosen matches your application.

2. Workshop Repairs and Servicing

Unlike some providers, MultiTorque does not offer on-site repairs. Instead, we perform all servicing in-house at our fully equipped workshops. This ensures every pump receives a thorough inspection, professional attention, and reliable results.

3. Customised Solutions

Every project is different. MultiTorque provides tailored diesel pump skid solutions, including custom trailer-mounted units, skid designs, and pump configurations.

4. Access to Trusted Brands

We supply and service leading pump brands such as Napco, NOV, Wilden, and Orbit. Customers benefit from our network of reliable suppliers and industry-leading parts availability.

5. Commitment to Reliability and Safety

At the heart of everything we do is our focus on long-term partnerships. MultiTorque values reliability, safety, and customer satisfaction above all else.

MultiTorque’s Approach to Diesel Pump Skids

When a customer contacts us for a diesel pump skid, we don’t just provide a generic solution. Instead, our process involves:

- Needs Assessment – Understanding the job requirements, fluid type, flow rates, and site conditions.

- Pump Selection – Matching the correct pump type and diesel engine combination.

- Skid Design – Providing stable and practical mounting options that suit the job.

- Testing and Quality Assurance – Ensuring the pump performs reliably before delivery.

- Ongoing Support – Offering workshop servicing, spare parts, and expert advice.

This end-to-end approach gives customers peace of mind that their investment in a diesel pump skid will deliver long-term results.

The Future of Diesel Pump Skid Technology

While diesel remains a dominant fuel source for mobile pump systems, the future will likely include more hybrid and eco-friendly designs. Skid-mounted units may integrate improved fuel efficiency, lower emissions engines, and even renewable-powered support systems.

MultiTorque stays up to date with industry developments, ensuring our customers always have access to the latest technology in pump systems.

Get in Touch with MultiTorque

If you need a diesel pump skid for your next project, partner with a trusted Australian supplier that puts reliability and service first. With over 15 years of industry experience, MultiTorque has the knowledge and equipment to keep your operations moving.

📍 Visit us online: www.multitorque.com.au

📞 Call us on: 1300 726 525

📧 Email: sales@multitorque.com

🔗 Connect with us: MultiTorque LinkedIn

Conclusion

A diesel pump skid is more than just a pump on a frame—it’s a dependable solution for industries that demand mobility, power, and durability. Whether it’s mining, construction, agriculture, or emergency response, MultiTorque delivers pump systems designed to perform.

By choosing MultiTorque, businesses gain more than just equipment; they gain a partner committed to reliability, safety, and long-term success.