When it comes to handling complex pumping requirements, Bornemann pumps stand out as some of the most reliable and versatile on the market. Known globally for their twin-screw pump technology, Bornemann has earned a reputation for delivering solutions in industries where efficiency, durability, and safety are paramount. At MultiTorque, we supply, service, and repair Bornemann pumps across Australia, ensuring our clients benefit from long-term reliability and performance in demanding environments.

📞 Call us today on 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

🔗 Connect with us on LinkedIn: MultiTorque Industries

Why Bornemann Pumps Are Industry Leaders

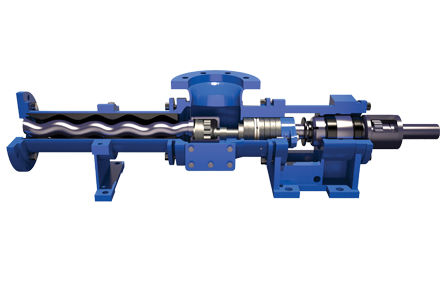

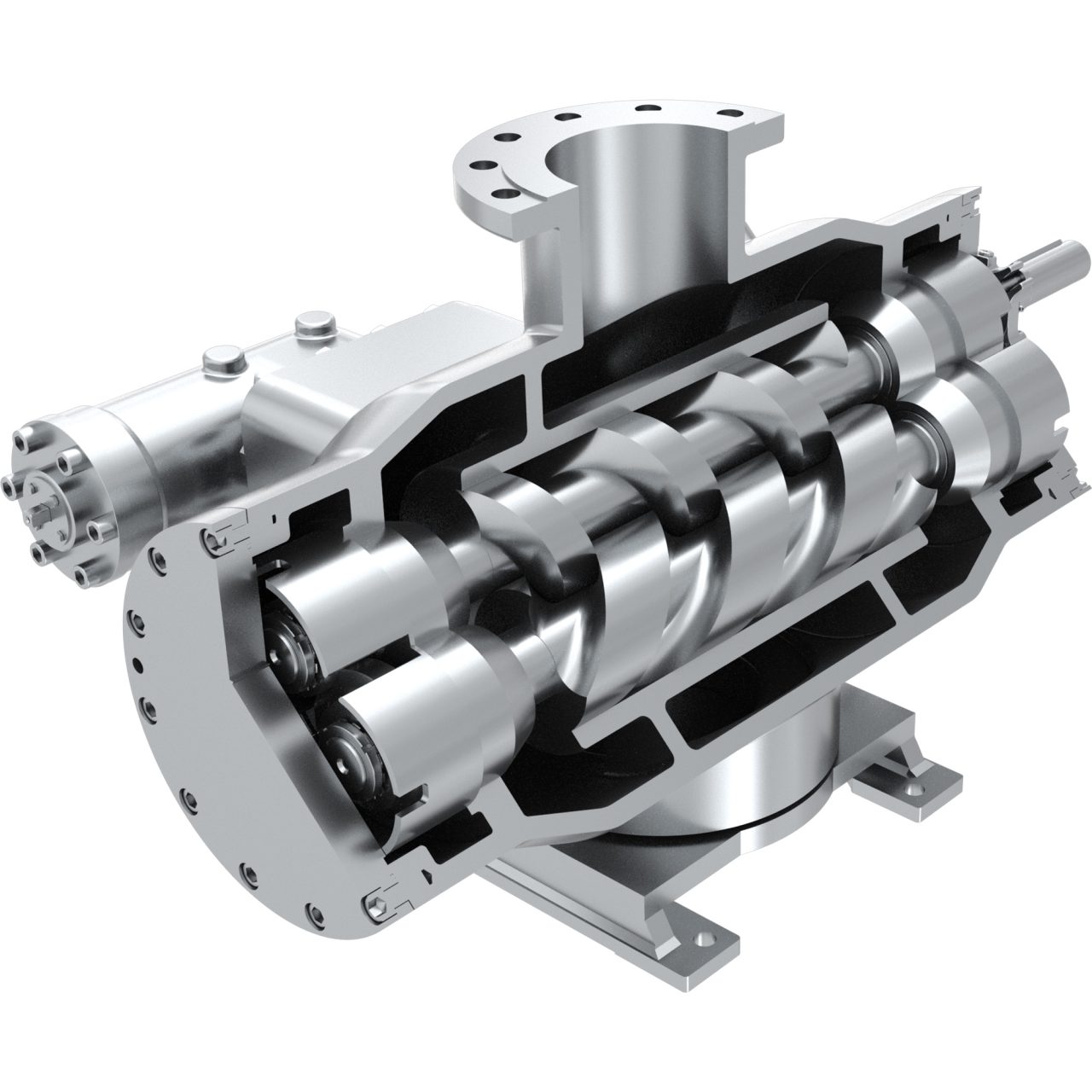

Bornemann pumps are designed with innovative twin-screw technology, making them ideal for applications involving viscous, abrasive, or multiphase fluids. Unlike traditional pump types, their unique design allows for continuous, low-pulsation flow without compromising on efficiency. This versatility makes Bornemann pumps a trusted choice in industries such as:

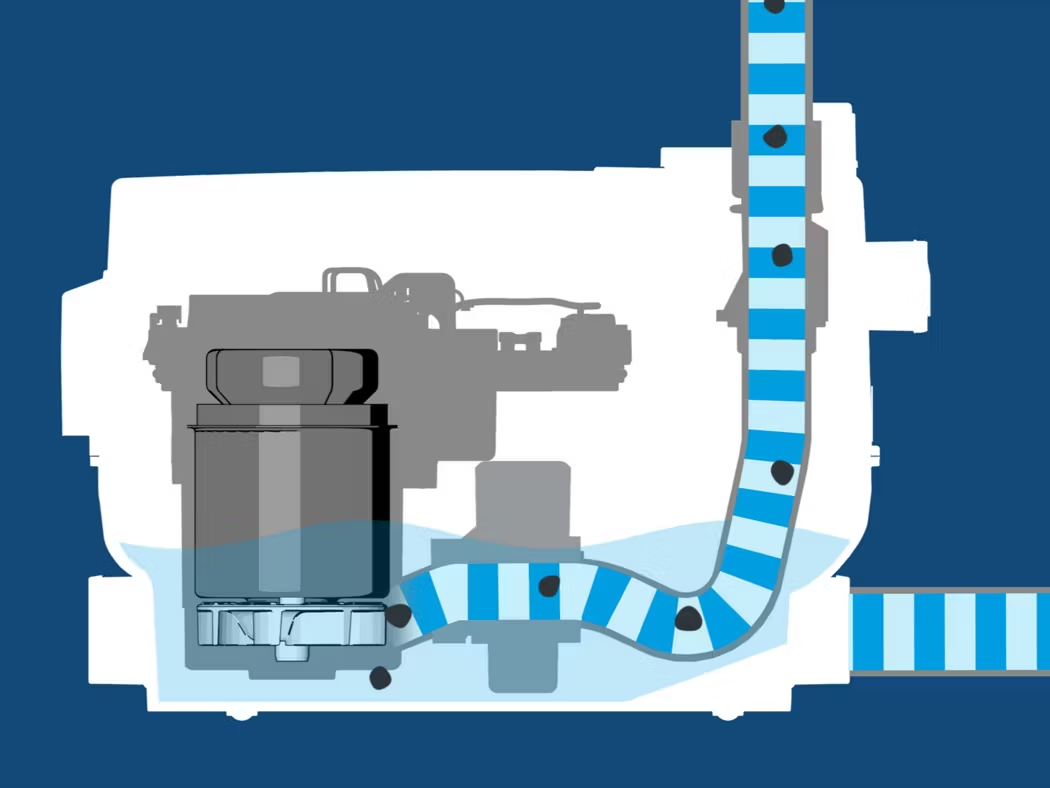

- Oil and gas – handling multiphase fluids directly from wells.

- Mining and minerals – transferring abrasive slurries and process fluids.

- Food and beverage – maintaining product integrity while pumping viscous or shear-sensitive materials.

- Chemicals and pharmaceuticals – delivering precision and safety when moving corrosive or hazardous fluids.

At MultiTorque, we understand how critical pump performance is to your operations. That’s why our team specializes in helping businesses select and maintain the right Bornemann pump for their application.

Key Benefits of Bornemann Pumps

- Twin-Screw Technology – Ensures smooth, consistent pumping with minimal vibration.

- Versatility – Handles liquids with varying viscosities, solids content, or even gas.

- Durability – Engineered for long service life, reducing maintenance costs.

- Low Pulsation – Protects sensitive products and reduces wear on pipelines.

- Efficiency – Optimized for energy savings, especially in continuous operations.

These benefits make Bornemann pumps an excellent long-term investment, especially for companies focused on improving uptime and reducing total cost of ownership.

MultiTorque: Your Partner for Bornemann Pump Solutions

As an Australian leader in industrial pumping solutions, MultiTorque provides comprehensive support for Bornemann pumps. Our services include:

- Supply of new Bornemann pumps – sourced directly to meet your exact requirements.

- Pump servicing and repairs – carried out in our fully equipped workshops in Perth and Brisbane.

- Parts and components – ensuring quick turnaround and minimal downtime.

- Custom solutions – including skid and trailer-mounted systems for mobile applications.

We pride ourselves on delivering more than just products—we provide long-term partnerships built on trust, reliability, and performance.

Applications of Bornemann Pumps in Australia

Given Australia’s vast resource and energy industries, Bornemann pumps are an essential part of operations across multiple sectors.

- Mining – In mineral processing plants, Bornemann twin-screw pumps handle slurries and chemical solutions with ease.

- Oil and Gas – Onshore and offshore operations use Bornemann multiphase pumps to simplify production and reduce the need for costly separation equipment.

- Food Processing – From dairy products to viscous sauces, Bornemann ensures gentle yet effective transfer without compromising quality.

- Chemical Plants – Their robust construction allows safe pumping of hazardous and corrosive fluids.

With their adaptability and proven track record, Bornemann pumps remain one of the most valuable assets in industrial operations.

Why Choose MultiTorque for Bornemann Pumps

MultiTorque has over 15 years of experience in supplying and servicing industrial pumping equipment across Australia. By choosing us as your Bornemann pump partner, you benefit from:

- Expert advice – Our team understands pump technology and can recommend the right solution for your needs.

- Local support – With workshops in Perth and Brisbane, we’re strategically positioned to service clients nationwide.

- Custom engineering – Whether you need a standalone pump or a fully integrated system, we can design and deliver a tailored solution.

- Commitment to reliability – We focus on long-term performance, ensuring your pump continues to deliver year after year.

When you need more than just a supplier, MultiTorque is here to be your trusted partner in all things pumping.

Contact MultiTorque Today

If your operation requires reliable pumping solutions, Bornemann pumps supplied and supported by MultiTorque are the right choice. Our team is ready to assist with supply, servicing, repairs, and custom builds tailored to your industry needs.

📞 Call us today on 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

🔗 Connect with us on LinkedIn: MultiTorque Industries

Final Thoughts

In industries where downtime costs money and reliability is non-negotiable, Bornemann pumps remain a proven choice for Australian businesses. With advanced twin-screw technology and unmatched versatility, they deliver performance in oil and gas, mining, chemical, and food applications alike. Backed by MultiTorque’s expertise and nationwide service capabilities, you can be confident that your investment in a Bornemann pump will deliver results for years to come.