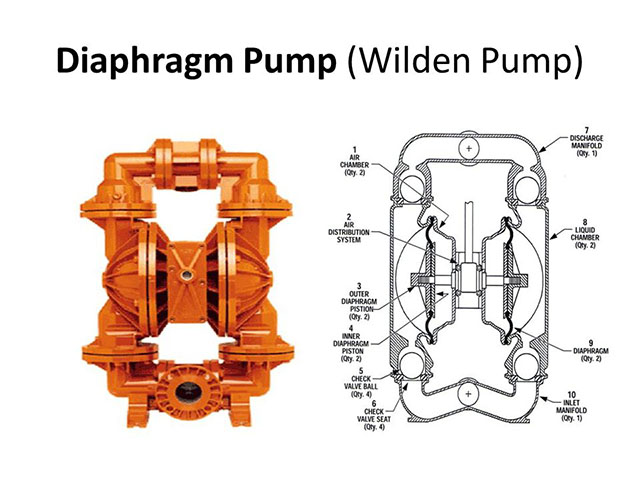

Wilden pumps are renowned for their durability, efficiency, and versatility in industrial fluid handling applications. From chemical processing and mining to wastewater management, these air-operated double diaphragm (AODD) pumps are trusted by industries worldwide. However, like any high-performance equipment, Wilden pumps require proper maintenance to continue performing optimally. One of the most effective ways to ensure long-term reliability is through a Wilden pump rebuild kit.

At MultiTorque, we supply genuine Wilden pump rebuild kits, replacement parts, and expert servicing across Australia. With over 15 years of experience, our team ensures your pumps operate at peak efficiency, reducing downtime and extending equipment life.

- 📞 Call 1300 726 525

- 📧 Email sales@multitorque.com

- 🌐 Visit www.multitorque.com.au

- 🔗 Connect with us on LinkedIn

What Is a Wilden Pump Rebuild Kit?

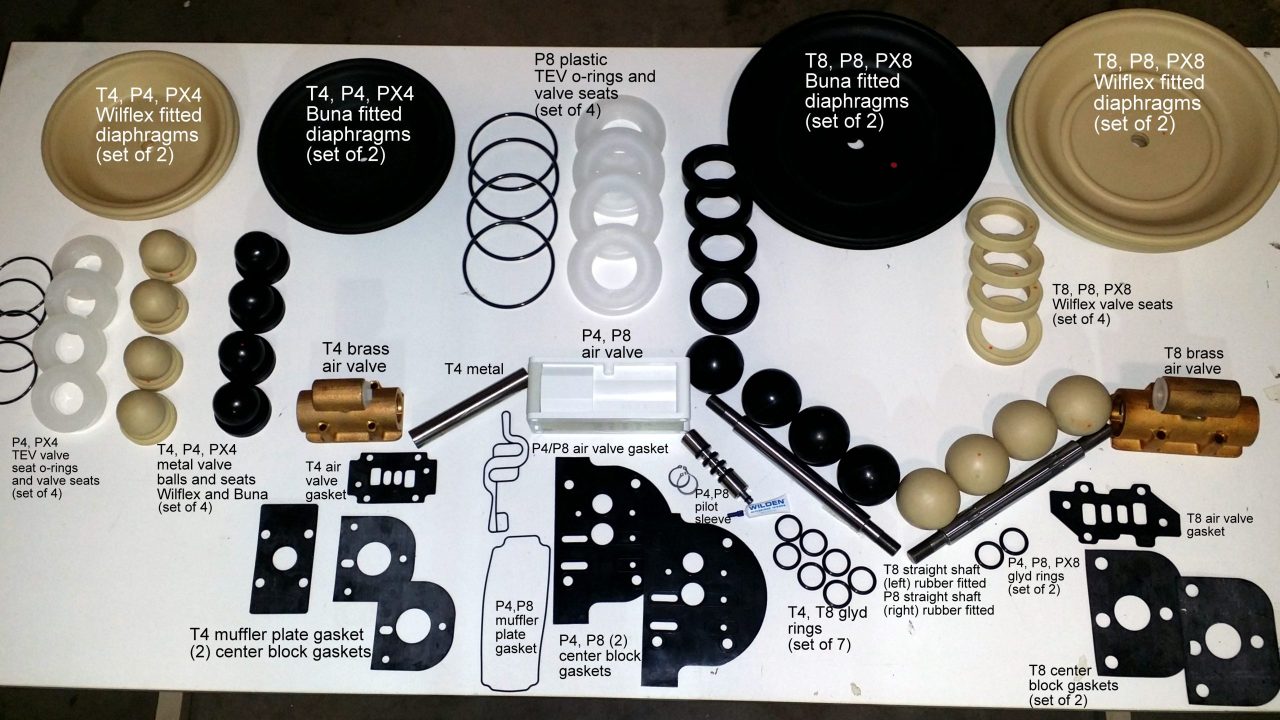

A Wilden pump rebuild kit is a comprehensive set of replacement components designed to restore a pump to “like-new” condition. These kits typically include:

- Diaphragms

- Valve balls and seats

- Seals and O-rings

- Gaskets

- Air valve components

Using a rebuild kit ensures that all critical wear parts are replaced at once, saving time and maintaining optimal performance. Regular use of rebuild kits prevents unexpected failures and extends the operational lifespan of your pump.

Benefits of Using a Wilden Pump Rebuild Kit

Investing in a Wilden pump rebuild kit offers numerous advantages for industrial operations:

1. Extended Pump Lifespan

Replacing worn components with a rebuild kit can significantly extend the life of your pump, preventing costly replacements and reducing downtime.

2. Consistent Performance

A rebuild kit restores the pump to its original efficiency, maintaining steady flow rates and pressure even under demanding conditions.

3. Cost-Effective Maintenance

Rather than replacing the entire pump, rebuild kits offer a budget-friendly way to maintain reliability and performance.

4. Reduced Downtime

With all critical parts replaced in one go, rebuild kits minimise the need for repeated maintenance and unplanned stoppages.

5. Genuine Parts

Using genuine Wilden parts ensures compatibility and longevity, which is crucial for high-wear components like diaphragms and valve seats.

Common Applications of Wilden Pumps

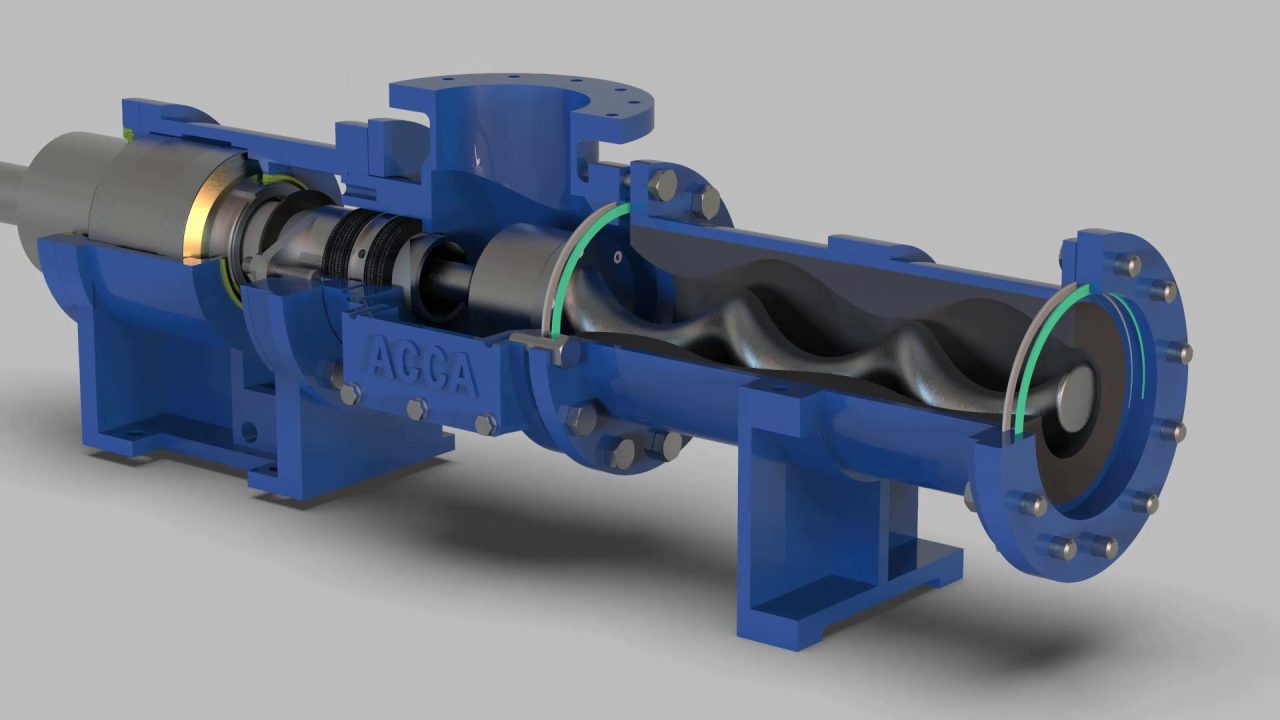

Wilden pumps are widely used across various industries due to their versatility and durability:

- Mining & Minerals – Transfer of slurries, mud, and abrasive fluids.

- Chemical Processing – Handling acids, bases, and corrosive solutions safely.

- Food & Beverage – Pumping syrups, oils, and other consumable liquids.

- Wastewater Management – Dewatering, sludge pumping, and chemical dosing.

- Manufacturing & Industrial – Circulation and transfer of fluids in production processes.

Regardless of the application, proper maintenance and rebuilds ensure Wilden pumps continue to perform reliably.

When to Use a Wilden Pump Rebuild Kit

Knowing when to rebuild your pump is essential for avoiding unexpected failures. Signs that a rebuild is necessary include:

- Reduced flow or pressure output

- Leaks around diaphragms, valves, or seals

- Unusual noises such as rattling, squealing, or hissing

- Pump stalling or inconsistent operation

- Visible wear or damage to diaphragms, O-rings, or valve seats

By addressing these signs early with a rebuild kit, you can prevent downtime and maintain operational efficiency.

Maintenance Tips for Wilden Pumps

Proper maintenance complements the use of a rebuild kit, ensuring long-term pump reliability:

- Regular Inspection – Check diaphragms, valves, and seals for wear.

- Scheduled Rebuilds – Follow manufacturer guidelines or operational hours to schedule rebuilds proactively.

- Lubrication & Cleaning – Keep air valves clean and lubricated as needed to prevent sticking or stalling.

- Correct Installation – Ensure all parts are installed correctly during rebuild to avoid leaks or inefficiencies.

At MultiTorque, our technicians provide in-house inspections, servicing, and rebuilds to ensure your Wilden pump operates at peak efficiency.

Why Choose MultiTorque for Wilden Pump Rebuild Kits?

MultiTorque is Australia’s trusted supplier of industrial pumps and parts. Our expertise in Wilden pumps ensures clients receive high-quality products and services. Key benefits of partnering with MultiTorque include:

- Genuine Wilden Parts & Rebuild Kits – Guaranteed compatibility and durability.

- Experienced Technicians – In-house servicing, inspections, and rebuilds.

- Custom Solutions – Tailored advice and rebuild strategies for your operational needs.

- Nationwide Support – Supplying and servicing pumps across Perth, Brisbane, and all of Australia.

- Long-Term Partnerships – Focused on reliability, safety, and ongoing client support.

Learn more about our services at MultiTorque’s homepage and connect with us on LinkedIn.

How MultiTorque Supports Pump Reliability

By providing genuine rebuild kits and expert servicing, MultiTorque helps businesses:

- Maintain consistent flow and pressure for industrial processes.

- Reduce operational downtime through proactive maintenance.

- Save money by extending the life of pumps instead of full replacements.

- Ensure safety and compliance when handling hazardous or corrosive fluids.

Our team works closely with clients to understand their operational requirements and provide tailored solutions that maximise pump performance.

Ordering a Wilden Pump Rebuild Kit

Getting a rebuild kit for your Wilden pump is simple with MultiTorque:

- Identify your pump model and operational requirements.

- Contact MultiTorque to confirm compatibility and availability.

- Our technicians can provide guidance on installation and preventative maintenance.

- Receive your rebuild kit and enjoy expert support throughout the process.

With MultiTorque, maintaining and rebuilding your Wilden pump has never been easier.

Contact MultiTorque Today

Ensure your Wilden pump continues delivering peak performance with expert support from MultiTorque:

- 📞 Call 1300 726 525

- 📧 Email sales@multitorque.com

- 🌐 Visit www.multitorque.com.au

- 🔗 Connect with us on LinkedIn

Partner with MultiTorque for genuine Wilden pump rebuild kits, replacement parts, and in-house servicing across Australia.