Industrial Pump Parts: What You Need to Know for Reliable Performance 2025

Industrial pump systems are the heart of operations across mining, manufacturing, wastewater, and chemical processing industries. At the core of keeping these systems running efficiently and safely lies one essential element: industrial pump parts. Whether you’re dealing with progressive cavity pumps, centrifugal systems, or high-pressure applications, understanding the importance of pump components and sourcing reliable replacements can dramatically reduce downtime and operational costs.

In this article, we’ll break down the critical components of industrial pumps, common issues caused by worn parts, and why choosing a trusted supplier like MultiTorque can save your business time and money.

The Role of Industrial Pump Parts in System Performance

Every pump is made up of intricate parts designed to work in unison to move fluids effectively. When even one component fails, the entire system can suffer — often leading to leaks, reduced flow, overheating, and unplanned shutdowns.

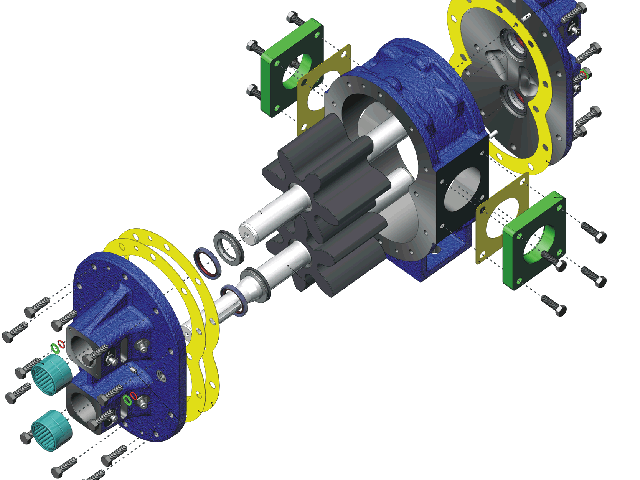

Common Industrial Pump Parts Include:

- Impellers – responsible for transferring energy to the fluid, crucial for flow rate and pressure.

- Seals and gaskets – ensure leak-free performance and protect internal components.

- Casings – enclose and support internal parts while containing the pressure.

- Bearings – reduce friction between moving components, promoting longevity.

- Shafts and sleeves – transmit torque and rotational energy while protecting against wear.

- Wear rings and liners – maintain clearances and reduce wear on impellers and casings.

These parts experience varying degrees of wear depending on the application, type of fluid, and system load. Choosing durable, compatible, and high-quality replacement parts is key to ensuring long-term pump health.

The Cost of Poor-Quality or Worn Pump Parts

Over time, even the best pump parts degrade under harsh conditions. When parts are not replaced on time — or replaced with low-quality alternatives — businesses may face:

- Unscheduled Downtime – Faulty parts cause failures that can halt production entirely.

- Higher Maintenance Costs – Worn components can damage neighboring parts.

- Reduced Efficiency – Leaks and worn impellers reduce flow rates and increase energy use.

- Environmental Hazards – Leaking seals or cracked casings can lead to spills and contamination.

- Shorter Equipment Lifespan – Continuous strain from failing parts leads to premature system failure.

To mitigate these risks, proactive maintenance and sourcing from a trusted industrial pump parts supplier is essential.

Why MultiTorque is the Trusted Name in Industrial Pump Parts

At MultiTorque, we supply, service, and repair a wide range of pump types used in Australian industries, including mining, agriculture, water management, oil & gas, and chemical processing. With branches in Perth and Brisbane, our reach and experience cover the country.

What Sets MultiTorque Apart?

✅ OEM and Aftermarket Options

We offer both genuine OEM parts and high-performance aftermarket components for brands like:

- Wilden

- Napco

- Orbit

- NOV

- And more

Whether you need a specific model replacement or a custom solution, we can help.

✅ Fast Turnaround

Downtime kills productivity. That’s why we stock a wide range of pump parts ready for dispatch. Our team ensures minimal lead times and urgent freight options for critical breakdowns.

✅ Technical Expertise

Not sure what part you need? Our team of pump experts can identify wear causes, recommend solutions, and even upgrade components for better system longevity.

✅ Custom Builds & Modifications

Need parts for a non-standard setup? We also fabricate components and custom trailer units under our BoreBoss brand to match unique site demands.

✅ Long-Term Support

With 15+ years of experience, we focus on building lasting client relationships — not just quick sales. Our service team supports your operation with ongoing inspections, advice, and full rebuilds when needed.

When to Replace Industrial Pump Parts

Preventive maintenance is the smartest way to avoid emergency repairs. Keep an eye out for these signs that indicate your parts may need replacing:

- Decreased flow rate or pressure

- Vibrations or strange noises during operation

- Overheating or frequent seal leaks

- High power consumption

- Increased downtime between maintenance

Using monitoring tools like flow meters, temperature sensors, and vibration analysis can also help track performance and detect issues before failure.

Applications That Demand Reliable Pump Parts

Industrial pump parts are vital in many sectors, including:

- Mining & Dewatering – Handling abrasive slurry, sediment-heavy fluids, or acidic mine water.

- Agricultural Irrigation – Moving large volumes of water through boreholes or surface systems.

- Wastewater & Treatment – Processing sludge and waste while maintaining hygiene and flow consistency.

- Chemical Transfer – Safely transporting corrosive or high-temperature fluids.

- Oil & Gas – Withstanding high pressure and harsh chemicals in hazardous environments.

Each of these industries puts unique demands on pump systems. That’s why you need pump parts that are matched not just to your pump — but to your application.

Partner with MultiTorque Today

Whether you’re sourcing replacement seals for a progressive cavity pump, impellers for a centrifugal pump, or a complete overhaul kit for a mine dewatering system — MultiTorque has you covered.

📞 Call us today on 1300 726 525 or

🌐 Visit www.multitorque.com.au

Or connect with us on LinkedIn for updates, product highlights, and industry insights.

Final Thoughts

The right industrial pump parts keep your systems efficient, your team safe, and your bottom line strong. Don’t risk your operations with sub-par components or suppliers. With MultiTorque, you get expert advice, proven reliability, and parts built for the harshest Australian conditions.