When operations depend on moving liquid fast, you need transfer pump suppliers who know their stuff—and deliver on time, every time. At MultiTorque, we supply, service, and custom-build transfer pump systems for clients across Australia in mining, oil & gas, wastewater, agriculture, and industrial sectors.

With over 15 years of hands-on industry experience, we’re one of Australia’s most reliable and responsive transfer pump suppliers, trusted for our expertise, turnaround speed, and commitment to keeping your systems running.

What Makes a Good Transfer Pump Supplier?

Not all transfer pump suppliers are created equal. The right supplier does more than just ship boxes—they provide tailored advice, carry trusted brands, offer local service, and understand the real-world conditions you’re working in.

At MultiTorque, we offer:

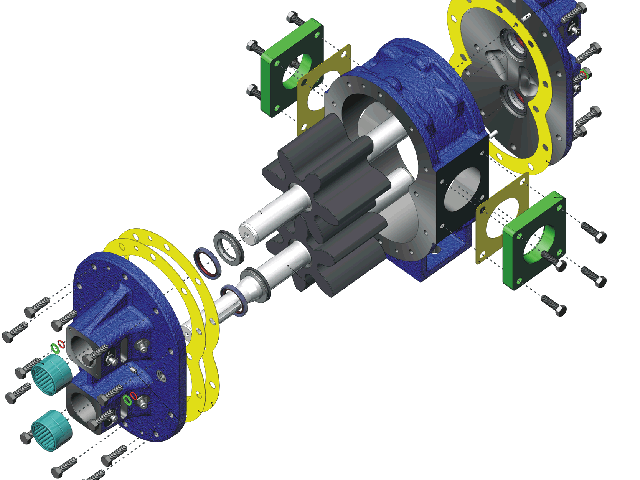

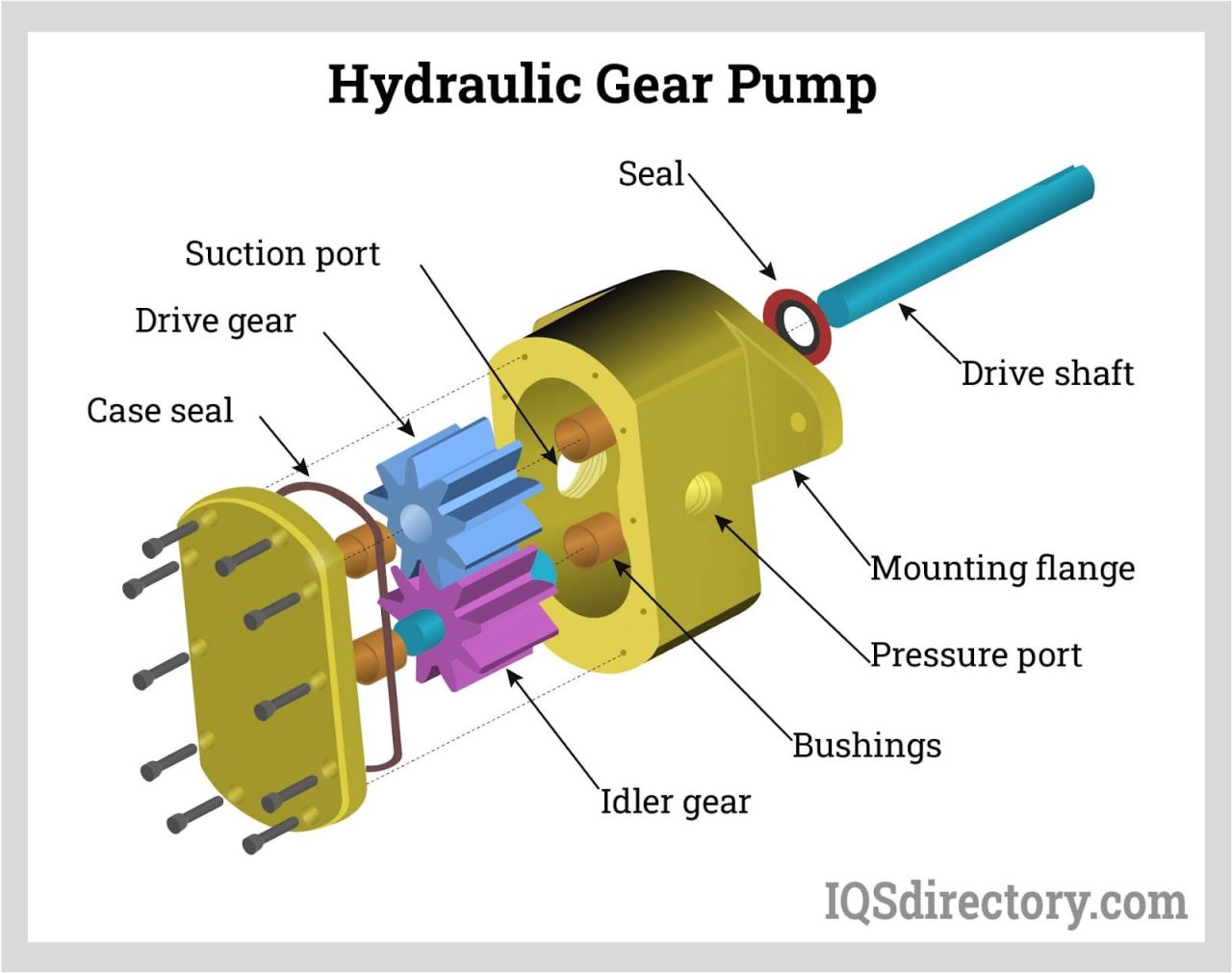

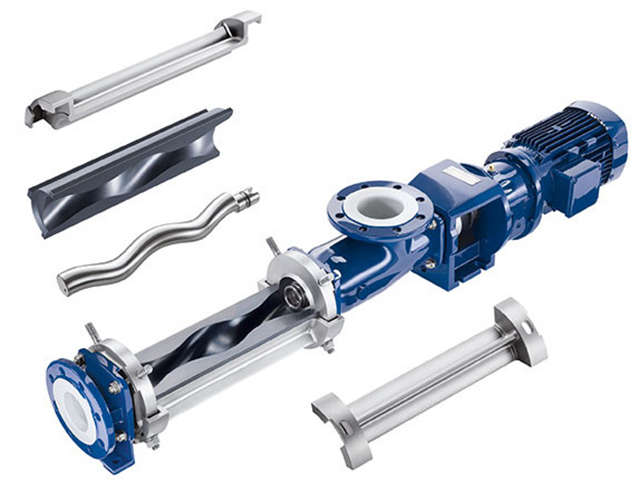

- ✅ A wide range of pump types (centrifugal, diaphragm, gear, vane, and more)

- ✅ Chemical-resistant options for fuel, caustic, and slurry transfer

- ✅ Full in-house servicing and repairs

- ✅ Rapid dispatch and local support from our Perth and Brisbane branches

- ✅ Custom-built mobile pump systems on skids or trailers

Whether you’re after a diesel transfer pump, a chemical dosing setup, or a full dewatering system, we’ll supply the right pump—built for Aussie conditions.

Our Range of Transfer Pumps

As one of Australia’s leading transfer pump suppliers, we provide high-performance units suitable for:

- 🚜 Diesel and fuel transfer

- 🌾 Agricultural and irrigation water movement

- 🧪 Chemical and caustic fluid handling

- 🏭 Slurry and wastewater processing

- 🔥 Emergency or portable transfer pump setups

We supply and service reputable brands including Napco, NOV, Wilden, Orbit, and more.

Explore our range:

🌐 www.multitorque.com.au

Need a Custom Transfer Pump System?

Sometimes off-the-shelf doesn’t cut it—and that’s where MultiTorque shines. We custom-build transfer pump systems designed for your site, budget, and application. That includes:

- ⚙️ Skid-mounted pump units

- 🚛 Trailer-based mobile transfer systems

- 🔌 Electric or diesel-driven configurations

- 🧪 Chemical and high-viscosity fluid setups

Perfect for mining dewatering, oilfield transfer, or agricultural work in remote regions. Tell us what you need moved—we’ll design the system to move it.

Servicing and Repairs You Can Count On

Many transfer pump suppliers leave you hanging when it comes to after-sale support. Not MultiTorque. We provide full in-house servicing for all major pump types, including:

- 🔧 Seal replacement and motor overhauls

- 🔄 Flow testing and rebalancing

- 🧰 Component upgrades and retrofits

- 📦 OEM parts supply for Napco, NOV, and others

We’re here to support the full lifecycle of your equipment, not just the initial sale.

Industries We Serve

We proudly supply transfer pumps and systems to:

- Mining and resource companies

- Oil & gas processing plants

- Agriculture and farming operations

- Wastewater and civil contractors

- Food & beverage and chemical manufacturers

Whatever your industry, if fluid needs moving—we’ve got the pump, the parts, and the people to make it happen.

Why Choose MultiTorque?

- 🚛 Rapid delivery and support from Brisbane and Perth

- 🔩 Huge stock of parts and pump models

- 💬 Technical support from real humans (not call centres)

- 🛠 In-house repair workshop

- 💯 Honest, long-term relationships

We’re not just transfer pump suppliers—we’re your partners in pumping performance.

Check out our latest work on LinkedIn:

🔗 Follow MultiTorque on LinkedIn

Contact MultiTorque Today

Looking for trusted transfer pump suppliers who deliver more than just product? Reach out to the team at MultiTorque.

📞 1300 726 525

📧 sales@multitorque.com

🌐 www.multitorque.com.au