When you need to start a diesel engine in the harshest conditions—without relying on batteries or electricity—a pneumatic starter for diesel engine systems is the answer. Rugged, reliable, and safe for hazardous environments, pneumatic starters use compressed air to deliver high torque starting power on demand.

At MultiTorque, we supply, service, and repair pneumatic starter motors for diesel engines across Australia. Whether it’s for mining machinery, backup generators, or remote installations, we’ve got the air-driven solutions to keep your engines running strong.

🔗 Visit MultiTorque Homepage

🔗 Follow us on LinkedIn

What Is a Pneumatic Starter for Diesel Engines?

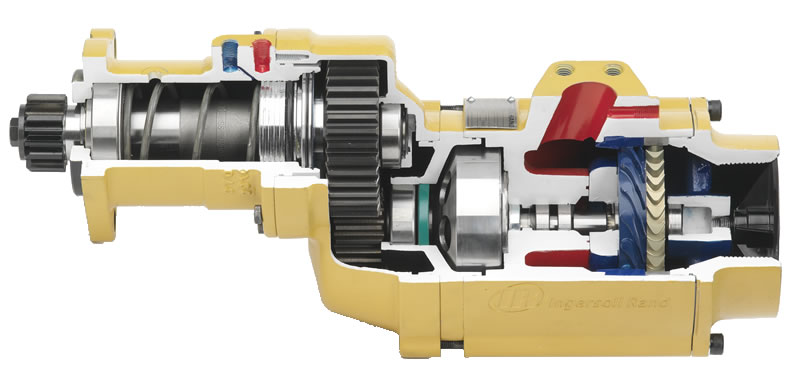

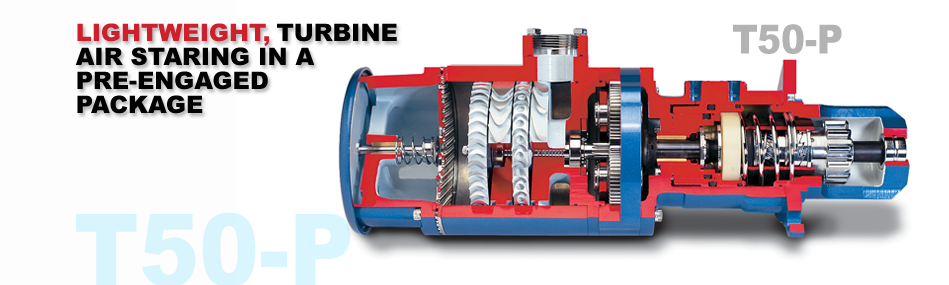

A pneumatic starter is an air-powered motor used to crank a diesel engine, initiating the combustion process. Instead of relying on electric batteries or hydraulic pressure, it uses compressed air—usually stored in an onboard tank—to spin the engine’s flywheel and start the engine.

Pneumatic starters are widely used in industries where:

- Explosive atmospheres prevent the use of electrical components

- Extreme temperatures make batteries unreliable

- Remote locations lack consistent electrical infrastructure

- Engine reliability is mission-critical

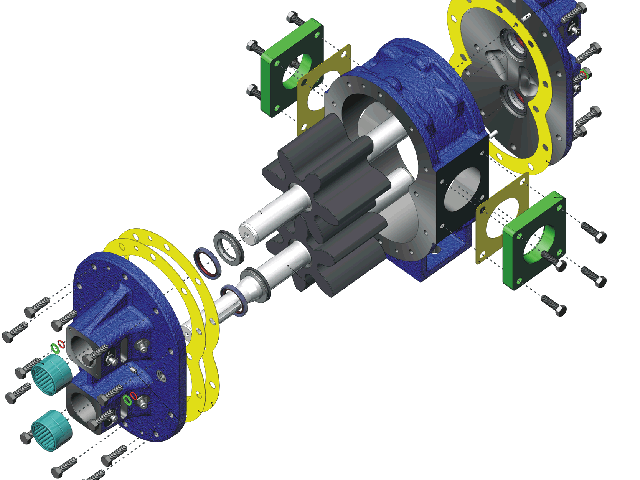

How Pneumatic Starters Work

Pneumatic starter systems operate by releasing high-pressure air from a reservoir through a control valve into the starter motor, which drives a pinion gear that engages with the engine’s flywheel. Once the engine fires up, the gear retracts, and the system resets for the next start.

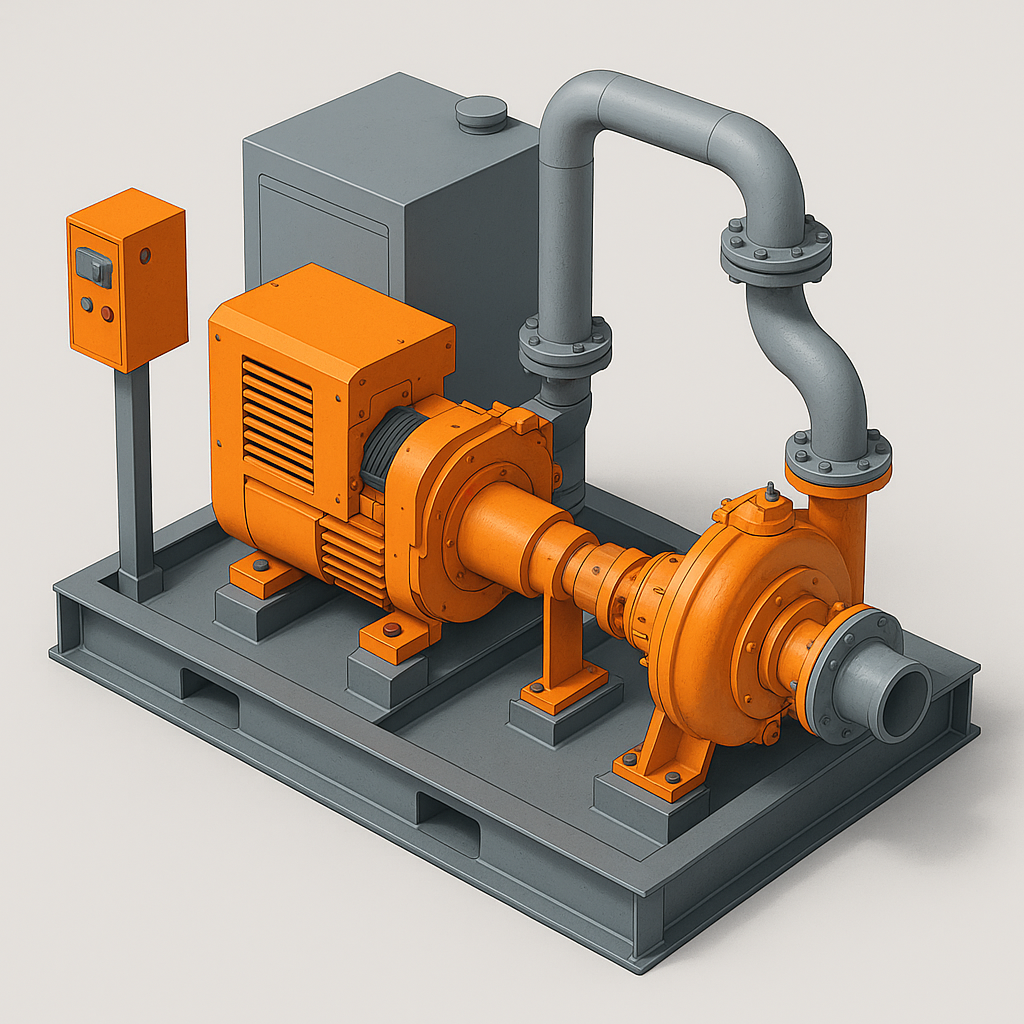

A typical setup includes:

- Pneumatic starter motor

- Air reservoir tank

- Control valves and regulators

- Filters and lubricators

- Safety shut-off systems

This makes the system simple, durable, and ideal for extreme-duty use.

Applications for Pneumatic Diesel Starters

Pneumatic starters are commonly found on:

- Mining machinery – Dozers, loaders, and portable compressors

- Power generation – Diesel backup generators and turbines

- Oil and gas – Equipment operating in Class 1 Division 1 or ATEX-rated zones

- Marine and offshore – Engines on ships, rigs, and platforms

- Military and aviation – Where rugged, battery-free starting is essential

- Remote industrial operations – Where infrastructure is limited

Benefits of Pneumatic Starters for Diesel Engines

✅ Battery-Free Starting

No more battery maintenance or failures. Perfect for off-grid, cold-weather, or explosive environments.

✅ Safe in Hazardous Zones

No sparks, no heat—making pneumatic starters ideal for oil, gas, and chemical applications.

✅ High Starting Torque

Compressed air delivers instant, powerful torque, even for large displacement diesel engines.

✅ Compact & Lightweight

Air starters are generally lighter and smaller than comparable electric or hydraulic systems.

✅ Minimal Maintenance

With fewer moving parts and no electrical systems, pneumatic starters require less maintenance and offer longer service life.

Pneumatic vs. Electric Starters

| Feature | Pneumatic Starter | Electric Starter |

|---|---|---|

| Power Source | Compressed air | Battery/electric |

| Suitable for Hazmat Zones | ✅ Yes | ❌ No |

| Maintenance | Low | Medium-High |

| Start Torque | High | Medium |

| Weather Reliability | Excellent | Poor in extreme cold |

| Repeated Starts | Multiple from air tank | Depends on battery charge |

For diesel engines in critical or remote locations, pneumatic starters offer unmatched reliability.

Brands and Models Supported by MultiTorque

We service and supply pneumatic starters compatible with major diesel engine brands, including:

- Caterpillar (CAT)

- Cummins

- Detroit Diesel

- Perkins

- Deutz

- MTU

- Komatsu

- John Deere

We also support leading air starter manufacturers such as:

- TDI (TurboTwin)

- Ingersoll Rand

- Gali

- Startmaster

Can’t find your model? No problem—our team can fabricate brackets, source compatible kits, or retrofit custom starter solutions.

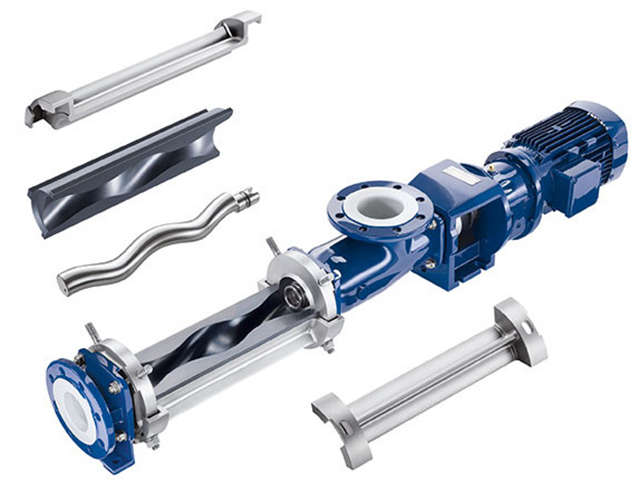

Pneumatic Starter System Components

A complete diesel engine pneumatic starting system includes:

- Air Starter Motor – The engine cranking mechanism

- Reservoir Tank – Stores compressed air for multiple starts

- Control Valve & Push Button – Triggers the air release

- Lubricator/Filter Assembly – Ensures clean, dry, lubricated air

- Check Valves & Safety Reliefs – Prevents backflow and overpressure

- Mounting Kit – Adapts starter to specific engine housing

At MultiTorque, we supply and install full systems or replacement parts.

Service, Repairs & Spare Parts

Need a repair or rebuild? MultiTorque offers:

- Starter rebuilds & pressure testing

- Seal and bearing replacements

- Pinion gear and shaft servicing

- Valve and air line diagnostics

- Preventative maintenance programs

- On-site inspection and replacement

From Perth to Brisbane, we’ve got mobile service units and rapid turnaround for downtime-sensitive clients.

Custom Engine Starter Solutions

Have a unique requirement? We engineer custom starting systems that include:

- Starter-motor assemblies

- Dual redundancy setups

- Compressed air skids

- Generator trailer starting packages

- Explosion-proof rated components

- Emergency bypass starter kits

Perfect for mines, fire systems, mobile plants, or offshore rigs—anywhere diesel engines need to start without fail.

Why Choose MultiTorque?

- 🔧 15+ years of experience in air-powered starter systems

- 💨 Australian experts in pneumatic and diesel integration

- 🚚 Fast parts supply and national service reach

- 🛠️ Stocking both OEM and aftermarket components

- 🤝 Trusted by mining, industrial, and energy clients nationwide

When the pressure’s on, MultiTorque delivers.

Get a Quote

Need a pneumatic starter for your diesel engine? Need it fast? We’ve got you covered.

📞 Call: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

🔗 Follow us on LinkedIn: MultiTorque Industries

Final Thoughts

A pneumatic starter for diesel engines offers reliability, safety, and simplicity in one rugged package. Whether you’re working in a remote mine, powering emergency generators, or maintaining ATEX-compliant equipment, this battery-free starting solution keeps your operation running when it matters most.

At MultiTorque, we don’t just sell parts—we keep your systems alive. With expert advice, on-site service, and custom-fit kits, we’ll keep your diesel starters locked, loaded, and ready for ignition.