Choosing the right fire prevention company is critical for businesses seeking to protect assets, personnel, and operations from fire risk. Industrial and commercial environments face unique challenges, from combustible materials and flammable liquids to mobile plant and high-risk infrastructure.

MultiTorque Fire Suppression is an Australian supplier and distributor of fire safety solutions, offering a full range of fire prevention equipment, suppression systems, and components for industries including mining, defence, marine, construction, transport, and manufacturing. With locations in Brisbane, Sydney, and Perth, MultiTorque provides local access and national coverage.

You can explore the full range of fire suppression products at https://fsequip.au/.

📞 Call 1300 726 525

📧 Email: sales@multitorque.com

🔗 Company: https://www.multitorque.com.au/

🔗 LinkedIn: https://www.linkedin.com/company/3176927

What a Fire Prevention Company Provides

A professional fire prevention company does more than supply equipment. Key services and offerings typically include:

- Fire risk assessment and advice

- Supply of fire extinguishers and suppression systems

- Provision of fire suppression system components and parts

- Support for compliance with Australian Standards and WHS regulations

- Recommendations for mobile plant, workshops, industrial sites, and marine applications

Businesses rely on fire prevention companies to not only supply products but also to provide guidance on selecting the right systems for their specific risks. MultiTorque ensures that all equipment is compliant, fit-for-purpose, and backed by industry expertise.

Fire Prevention Solutions Supplied by MultiTorque

MultiTorque supplies a full spectrum of fire prevention and protection equipment, including:

- Portable fire extinguishers from trusted brands such as Amerex and ECCO

- Large wheeled fire extinguishers for industrial and marine use

- Foam fire suppression systems

- Gas-based and clean agent fire suppression systems

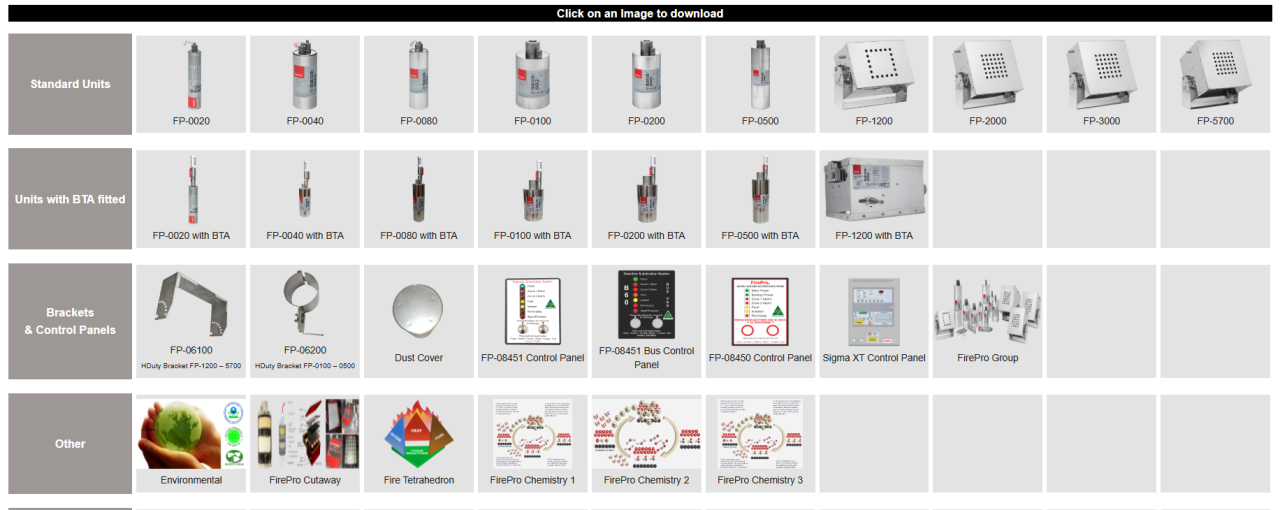

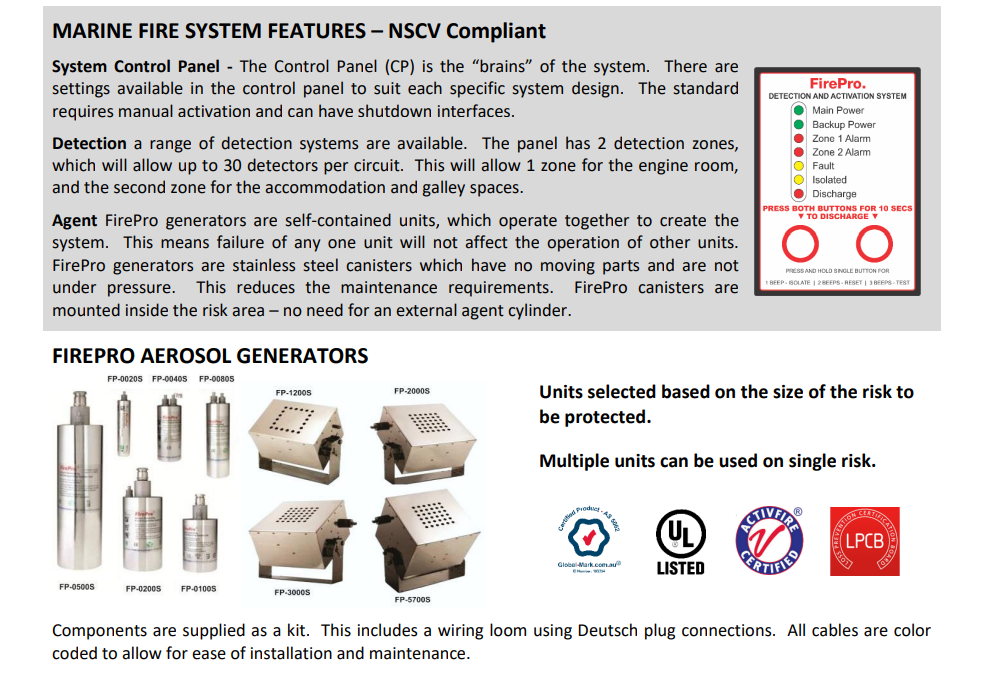

- FirePro condensed aerosol fire suppression systems (MultiTorque is an official distributor)

- Fire suppression system parts and components

For specialised fire suppression solutions, MultiTorque provides equipment suitable for high-risk, industrial, and mobile applications. You can explore the full range of products at https://fsequip.au/.

Industries That Benefit From Fire Prevention Companies

A fire prevention company plays a vital role across industries where fire risk is high. MultiTorque supplies solutions to businesses in:

- Mining and resources

- Defence

- Marine and ports

- Construction and civil works

- Transport and logistics

- Industrial manufacturing

- Power and energy infrastructure

Each industry has unique fire risks, from flammable liquids in mining operations to electrical hazards in control rooms. MultiTorque ensures all fire prevention solutions are tailored to these environments.

Compliance and Safety Considerations

Working with a reputable fire prevention company ensures your business remains compliant with:

- Australian Standards (AS) for fire safety equipment

- Workplace Health and Safety (WHS) regulations

- Industry-specific safety requirements

Non-compliance can result in legal penalties, increased insurance costs, and heightened safety risks. MultiTorque supplies certified equipment and provides guidance to support compliance across all sectors.

Why Choose MultiTorque as Your Fire Prevention Company

Businesses choose MultiTorque because we combine industry knowledge, decades of experience, and a full product range. Key advantages include:

- Comprehensive fire prevention and suppression solutions

- Official distribution of FirePro aerosol systems

- National supply with local accessibility in Brisbane, Sydney, and Perth

- Expertise across multiple high-risk industries

- Ability to support large-scale projects and fleet-wide installations

By working with MultiTorque, businesses gain a trusted partner for all fire prevention and protection needs, ensuring both compliance and peace of mind.

Fire Prevention Company – Contact MultiTorque

If you are seeking a reliable fire prevention company to supply fire suppression equipment, extinguishers, or parts, MultiTorque is ready to assist.

📞 Call 1300 726 525

📧 Email: sales@multitorque.com

🔗 Company: https://www.multitorque.com.au/

🔗 LinkedIn: https://www.linkedin.com/company/3176927