When it comes to industrial safety, partnering with a reliable fire safety equipment company is essential for protecting personnel, assets, and operations. Australian industries, from mining and transport to manufacturing and marine, face complex fire risks that demand trusted solutions. MultiTorque Industries, with over 15 years of engineering and industrial expertise, is a leading fire safety equipment company delivering high-performance, compliant, and reliable fire safety solutions nationwide.

Through the strategic acquisition of Fire Safety Equipment (FSEquip), MultiTorque has strengthened its position as a top provider of fire protection and safety equipment, ensuring industrial clients have access to the most effective systems and components available.

📞 Phone: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: MultiTorque Industries

🔗 LinkedIn: Connect with MultiTorque

🔥 Fire suppression expertise: FSEquip

What Makes a Fire Safety Equipment Company Essential?

A professional fire safety equipment company does more than supply products — it provides solutions that prevent, detect, and suppress fires while ensuring compliance with Australian standards. Key offerings from a trusted company include:

- Fire suppression systems: Aerosol, gas, foam, and dry chemical systems for industrial, mobile, and fixed applications.

- Detection and alarm systems: Early warning devices to detect and respond to fire threats promptly.

- Safety equipment and PPE: Extinguishers, personal protective equipment, and other compliance essentials.

- Customised fire safety solutions: Systems tailored to unique operational environments and risks.

By working with an experienced fire safety equipment company, businesses ensure their operations remain safe, compliant, and operationally resilient.

MultiTorque’s Expertise as a Fire Safety Equipment Company

MultiTorque combines engineering knowledge with industrial safety expertise to provide complete solutions that meet the demands of Australian industries. Through FSEquip, we supply and source a wide range of fire safety equipment for mobile, fixed, and industrial applications.

1. Mobile Equipment Fire Safety Solutions

Mining, transport, and construction operations involve heavy machinery in high-risk environments. MultiTorque provides components and systems for mobile fire safety, including:

- Control modules and actuators

- Fire suppression agents

- Detection and alarm units

These systems protect critical machinery such as haul trucks, loaders, and drill rigs, reducing downtime while maintaining safety and compliance.

2. Fixed Fire Safety Installations

Facilities such as warehouses, processing plants, fuel depots, and marine workshops require permanent fire safety systems. MultiTorque, through FSEquip, supplies detection, suppression, and alarm components compatible with AS/NZS standards. These systems ensure reliable performance and protection for both people and assets in high-risk environments.

3. Customised Fire Safety Solutions

Every industrial site has unique challenges, and MultiTorque specialises in custom fire safety solutions. Whether your operations involve lithium battery storage, mobile plant, or heavy machinery, we design and source systems tailored to your site’s risks, ensuring maximum protection, minimal maintenance, and regulatory compliance.

FirePro: Innovative Fire Safety Systems

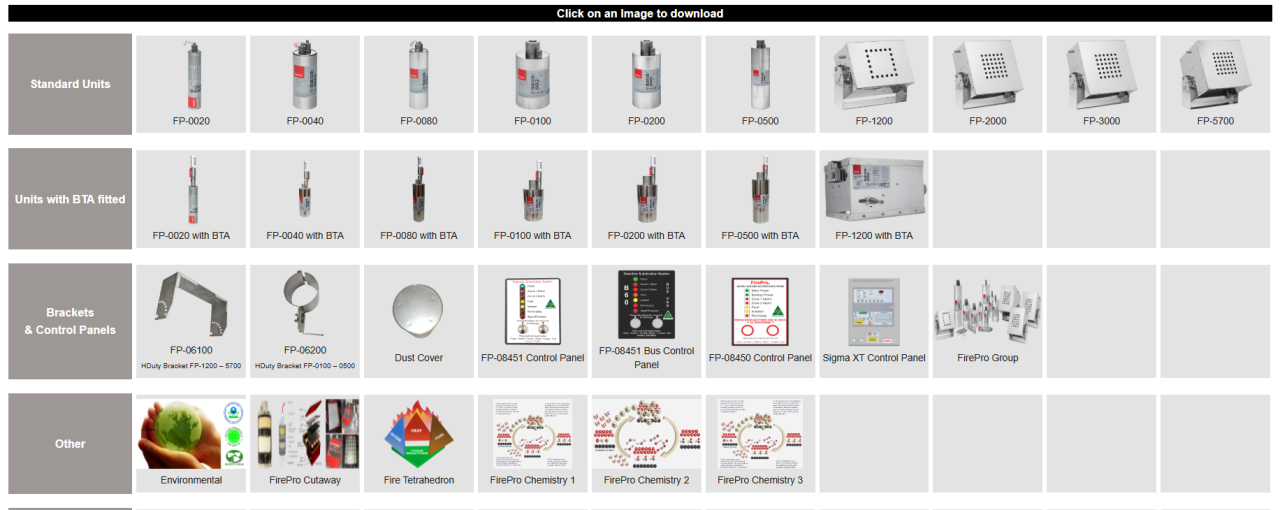

As part of our comprehensive fire safety offerings, MultiTorque proudly distributes FirePro, a pre-engineered condensed aerosol fire suppression system. MultiTorque is the official distributor in Australia (not the owner) and provides FirePro systems for a variety of industrial applications.

FirePro highlights:

- Electrically or thermally activated

- No high-pressure cylinders or pipework required

- Minimal maintenance with a space-saving design

- Certified to AS 4487 Aerosol Systems and AS 5062 Mobile Plant

- Environmentally friendly

Applications include mining, agriculture, vehicle/mobile plant, marine, manufacturing, lithium battery protection, buses, rail systems, cabinets, and power infrastructure.

👉 For FirePro solutions and fire suppression systems, visit: FSEquip

Industries Served by MultiTorque

MultiTorque provides fire safety equipment across multiple Australian industries, offering tailored solutions for each sector:

- Mining & Resources: Mobile and fixed fire safety systems for machinery, fuel storage, and underground operations.

- Transport & Logistics: Fire safety equipment for fleets, depots, and loading areas.

- Oil & Gas: Explosion-proof fire protection for hazardous environments.

- Civil & Construction: Fire systems for heavy machinery and mobile workstations.

- Marine & Ports: Bilge, ballast, and dockside fire safety solutions.

- Manufacturing & Industrial: Systems for factories, workshops, and chemical processing facilities.

- Agriculture & Irrigation: Protection for pumps, engines, and remote operations.

By supplying customised and reliable fire safety equipment, MultiTorque ensures industrial workplaces are safe, compliant, and operationally resilient.

Why MultiTorque is the Fire Safety Equipment Company You Can Trust

MultiTorque’s expertise and dedication make us a leading fire safety equipment company in Australia.

Key reasons to choose MultiTorque:

- Experience: Over 15 years serving Australian industrial sectors.

- Technical expertise: Skilled engineers capable of sourcing, integrating, and maintaining fire safety systems.

- Nationwide coverage: Branches in Perth, Brisbane, and Sydney.

- Reliability: Certified and proven equipment built for industrial environments.

- Integrated solutions: Access to FSEquip expertise and FirePro aerosol fire suppression systems.

Partnering with MultiTorque guarantees your business receives fire safety equipment that performs under the most demanding conditions.

Contact MultiTorque for Fire Safety Equipment Solutions

Ensure your industrial operations are protected with a trusted fire safety equipment company.

📞 Phone: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: MultiTorque Industries

🔗 LinkedIn: Connect with MultiTorque

🔥 Fire suppression expertise: FSEquip

MultiTorque — delivering reliable, compliant, and high-performance fire safety equipment for Australian industries.